31

20034293

GB

Start-up, calibration and operation of the burner

6.8

Pressure switch adjustment

6.8.1

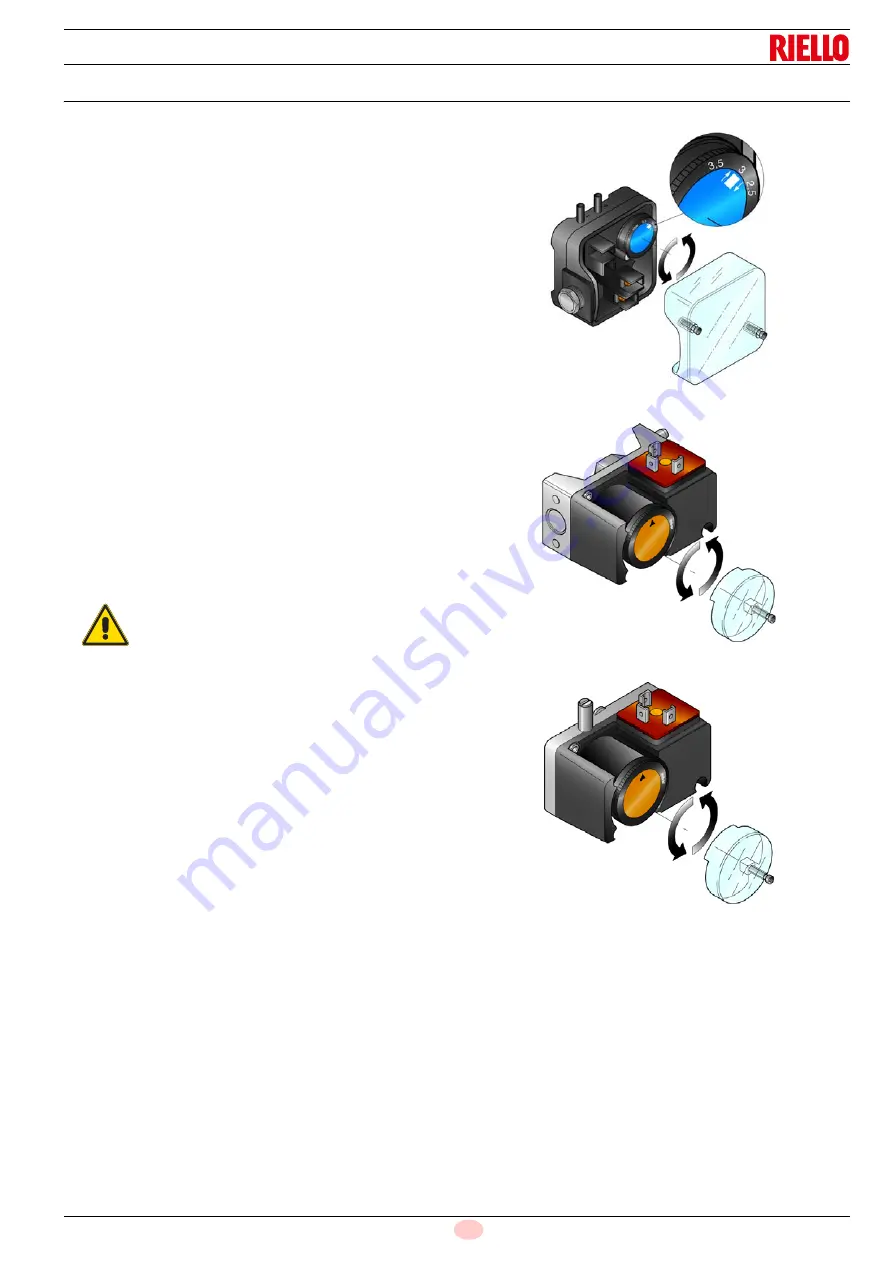

Air pressure switch

Adjust the air pressure switch after having performed all other

burner adjustments with the air pressure switch set to the start of

the scale (Fig. 39).

With the burner working at MIN output, insert a combustion ana-

lyser in the stack, slowly close the suction inlet of the fan (for ex-

ample, with cardboard) until the CO value does not exceed 100

ppm.

Then slowly turn the appropriate knob clockwise until the burner

reaches the lockout position.

Check the indication of the arrow pointing upwards on the gradu-

ated scale (Fig. 39).

Turn the knob clockwise again, until the value shown on the grad-

uated scale corresponds with the arrow pointing downwards, and

so recovering the hysteresis of the pressure switch (shown by the

white mark on a blue background, between the two arrows).

Now check the correct start-up of the burner.

If the burner locks out again, turn the knob anticlockwise a little

bit more.

The incorporated air pressure switch can work in a “differential”

mode if connected with two pipes. If a negative pressure in the

combustion chamber during pre-purging prevents the air pres-

sure switch from switching. Switching may be obtained by fitting

a second pipe between the air pressure switch and the suction in-

let of the fan. In such a manner the air pressure switch operates

as differential pressure switch.

6.8.2

Maximum gas pressure switch

Adjust the maximum gas pressure switch after having performed

all the other burner adjustments with the maximum gas pressure

switch set at the end of the scale (Fig. 40).

With the burner operating at MAX output, reduce the adjustment

pressure by slowly turning the relative knob anticlockwise until

the burner locks out.

Then turn the knob clockwise by 2 mbar and repeat burner firing.

If the burner locks out again, turn the knob again clockwise by 1

mbar.

6.8.3

Minimum gas pressure switch

Adjust the minimum gas pressure switch after having performed

all the other burner adjustments with the pressure switch set at

the start of the scale (Fig. 41).

With the burner operating at MAX output, increase adjustment

pressure by slowly turning the relative knob clockwise until the

burner locks out.

Then turn the knob anti-clockwise by 2 mbar and repeat burner

starting to ensure it is uniform.

If the burner locks out again, turn the knob anti-clockwise again

by 1 mbar.

WARNING

The use of the air pressure switch with differential

operation is allowed only in industrial applications

and in places where national rules enable the air

pressure switch to control only fan operation.

Fig. 39

D3951

Fig. 40

D3856

Fig. 41

D3855

Summary of Contents for RLS 250/M

Page 2: ...Original instructions ...

Page 45: ...43 20034293 GB Appendix Electrical panel layout ...

Page 46: ...20034293 44 GB Appendix Electrical panel layout ...

Page 47: ...45 20034293 GB Appendix Electrical panel layout ...

Page 48: ...20034293 46 GB Appendix Electrical panel layout ...

Page 49: ...47 20034293 GB Appendix Electrical panel layout ...

Page 51: ......