20034293

16

GB

Installation

5.6.2

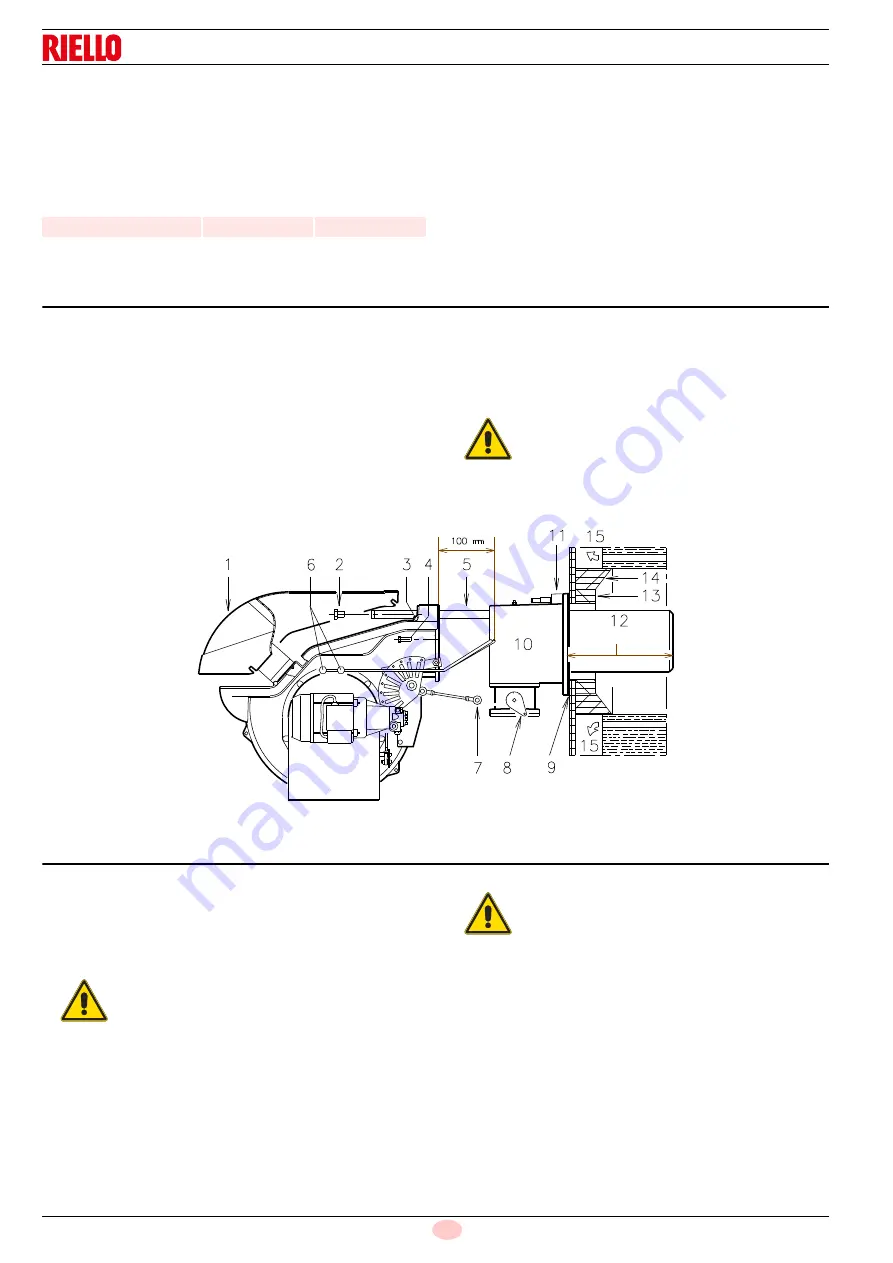

Blast tube length

The length of the blast tube must be selected according to the in-

dications provided by the manufacturer of the boiler, and in any

case it must be greater than the thickness of the boiler door com-

plete with its fettling.

The range of lengths available, L (mm), is as follows:

Tab. I

For boilers with front flue passes 15)(Fig. 10) or flame inversion

chambers, protective fettling in refractory material 13) must be in-

serted between the boiler fettling 14) and the blast tube 12).

This protective fettling must not compromise the extraction of the

blast tube.

For boilers having a water-cooled front the refractory fettling 13)-

14)(Fig. 10) is not required unless it is expressly requested by the

boiler manufacturer.

5.7

Securing the burner to the boiler

Detach the combustion head from the burner:

disconnect the hoses by unscrewing the two connectors

6)(Fig. 10).

Disengage the articulated coupling 7) from the graduated

sector 8).

Loosen the 4 screws 3) and remove the cover 1).

Remove the screws 2) from the slide bars 5).

Remove the 2 screws 4) and pull the burner back on slide

bars 5) by about 100 mm.

Disconnect the electrode wires and then pull the burner

completely off the slide bars.

Secure the sleeve with flange 11) to the boiler plate, inter-

posing the thermal insulating screen 9) supplied with the

burner.

Use the 4 screws, also supplied with the unit, after first pro-

tecting the thread with an anti-locking product.

5.8

Nozzles

The burner complies with the emission requirements of the

EN 267 standard.

In order to guarantee that emissions do not vary, recommended

and/or alternative nozzles specified by Riello in the Instruction

and warning booklet should be used.

Short

Long

RLS 250/M MZ

418

548

WARNING

The seal between burner and boiler must be air-

tight.

Fig. 10

D8911

WARNING

It is advisable to replace nozzles every year

during regular maintenance operations.

CAUTION

The use of nozzles other than those specified by

Riello S.p.A. and inadequate regular maintenance

may result into emission limits non-conforming to

the values set forth by the regulations in force, and

in extremely serious cases, into potential hazards

to people and objects.

The manufacturing company shall not be liable for

any such damage arising from nonobservance of

the requirements contained in this manual.

Summary of Contents for RLS 250/M

Page 2: ...Original instructions ...

Page 45: ...43 20034293 GB Appendix Electrical panel layout ...

Page 46: ...20034293 44 GB Appendix Electrical panel layout ...

Page 47: ...45 20034293 GB Appendix Electrical panel layout ...

Page 48: ...20034293 46 GB Appendix Electrical panel layout ...

Page 49: ...47 20034293 GB Appendix Electrical panel layout ...

Page 51: ......