17

20034293

GB

Installation

5.8.1

Choice of nozzles for 1

st

and 2

nd

stage

Both nozzles must be chosen from among those listed in Tab. J.

The first nozzle determines the delivery of the burner in the 1st

stage.

The second nozzle works together with the 1st nozzle to deter-

mine the delivery of the burner in the 2nd stage.

The deliveries of the 1st and 2nd stages must be contained within

the value range indicated on pag. 9.

Use nozzles with a 60° spray angle at the recommended pres-

sure of 12 bar.

As a rule the two nozzles have equal deliveries but the 1st stage

nozzle may have a delivery less than 50% of the total delivery

when a reduction of the counter-pressure peak is desired at the

moment of starting (the burner allows good combustion rates

also with a 40 - 100 % ratio between the 1st and 2nd stage).

Example

Boiler output = 1630 kW - efficiency 90 %

Output required by the burner:

1630 : 0.9 = 1812 kW

per nozzle:

1812 : 2 = 906 kW

therefore, two equal, 60°, 12 bar nozzles are required:

1° = 18 GPH - 2° = 18 GPH,

or the following two different nozzles:

1° = 16 GPH - 2° = 20 GPH

Nozzle DELAVAN B 60°

Tab. J

5.8.2

Nozzle assembly

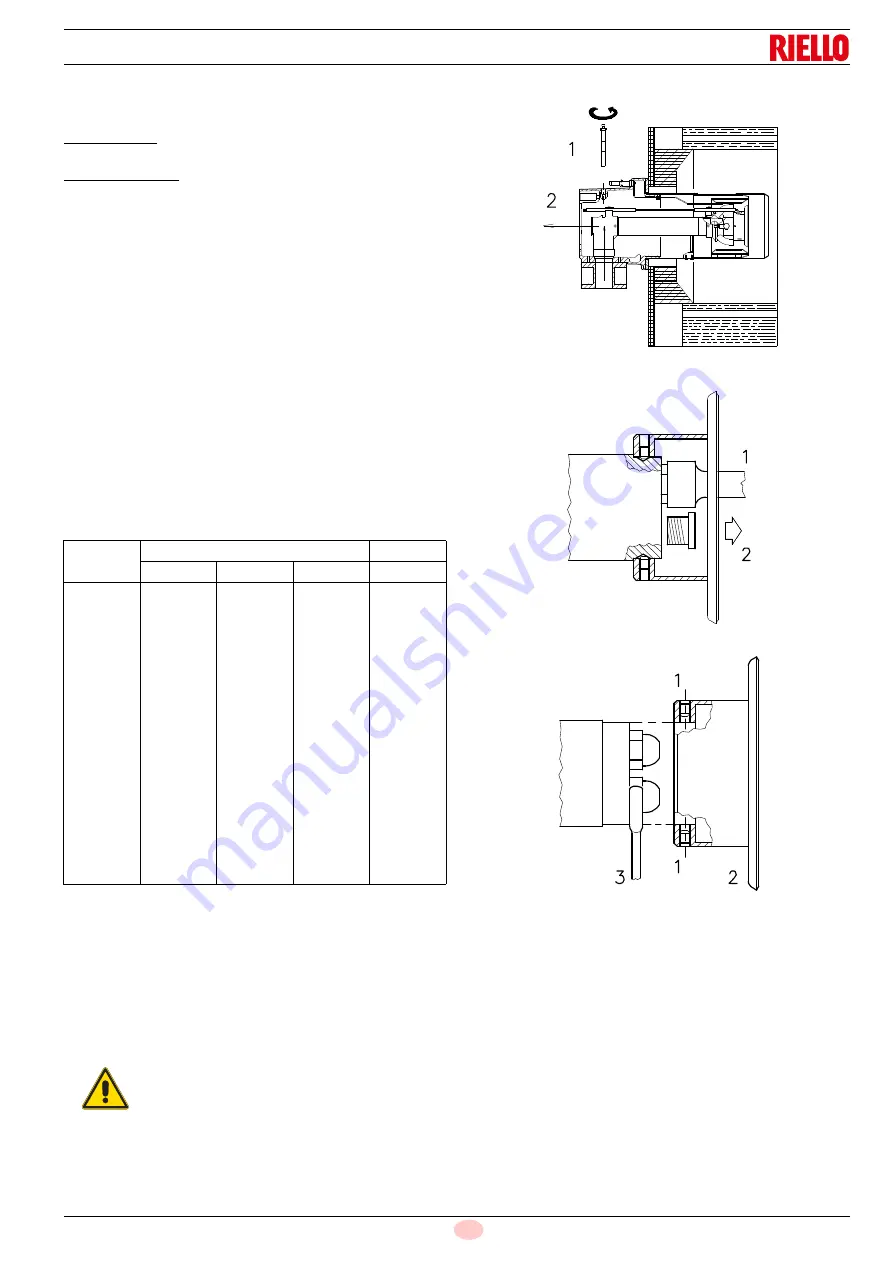

Remove screw 1)(Fig. 11) and extract the internal part 2).

Fit two nozzles with the box spanner (16 mm) 1)(Fig. 12),

after having removed the plastic plugs 2).

Fitting the spanner through the central hole in the flame sta-

bility disk or loosen screws 1)(Fig. 13).

Remove disk 2)(Fig. 13) and replace the nozzles using the

wrench 3).

The nozzle for the 1

st

stage of operation is the one lying beneath

the firing electrodes (Fig. 14).

GPH

kg/h

kW

10 bar

12 bar

14 bar

12 bar

12.0

13.0

14.0

15.0

16.0

17.0

18.0

19.0

20.0

22.0

24.0

25.0

26.0

28.0

30.0

32.0

34.0

35.0

44.16

47.84

51.52

55.20

58.88

62.57

66.25

69.93

73.61

80.97

88.33

92.00

95.69

103.05

110.41

117.77

125.13

128.81

48.73

52.79

56.86

60.92

64.98

69.04

73.10

77.16

81.22

89.34

97.47

101.53

105.59

113.71

121.83

129.95

138.08

142.14

52.96

57.38

61.79

66.20

70.62

75.03

79.44

83.86

88.27

97.10

105.93

110.34

114.75

123.58

132.41

141.24

150.06

154.48

582.36

630.89

679.42

727.95

776.48

825.01

873.54

922.07

970.60

1067.66

1164.72

1198.00

1261.78

1358.84

1455.90

1533.47

1629.31

1667.23

WARNING

Do not use any sealing products such as gaskets,

sealing compound, or tape.

Be careful to avoid damaging the nozzle sealing

seat. The nozzles must be screwed into place

tightly but not to the maximum torque value pro-

vided by the wrench.

Fig. 11

D3172

Fig. 12

D1146

Fig. 13

D1147

Summary of Contents for RLS 250/M

Page 2: ...Original instructions ...

Page 45: ...43 20034293 GB Appendix Electrical panel layout ...

Page 46: ...20034293 44 GB Appendix Electrical panel layout ...

Page 47: ...45 20034293 GB Appendix Electrical panel layout ...

Page 48: ...20034293 46 GB Appendix Electrical panel layout ...

Page 49: ...47 20034293 GB Appendix Electrical panel layout ...

Page 51: ......