20017786

18

Installation

4.5

Securing the burner to the boiler

4.5.1

Boring the boiler plate

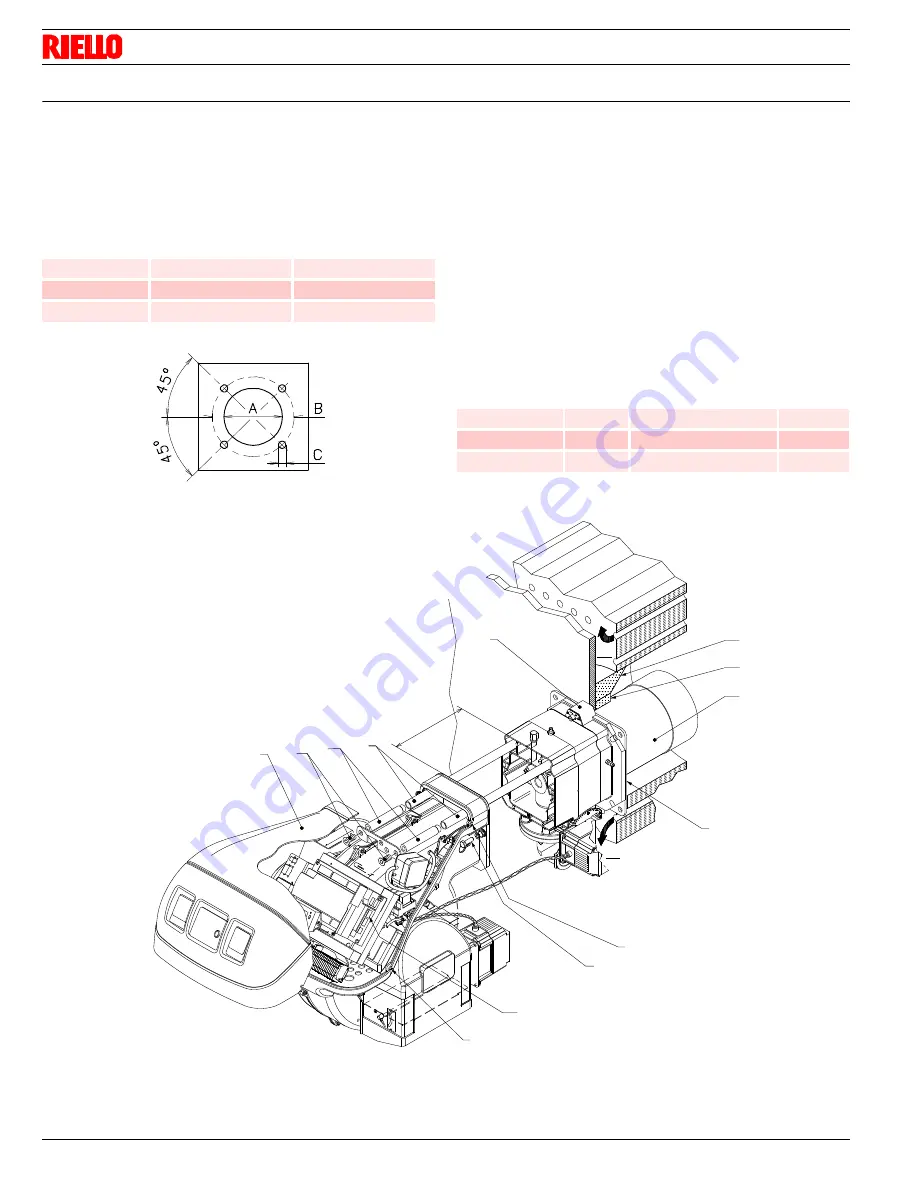

Make holes in the plate shutting off the combustion chamber, as il-

lustrated in Fig. 10.

The position of the threaded holes can be marked using the ther-

mal insulation screen supplied with the burner.

Tab. K

4.5.2

Length of the blast tube

The length of the blast tube must be selected according to the

indications provided by the manufacturer of the boiler, and in

any case it must be greater than the thickness of the boiler door

complete with its refractory. The available lengths L are those in-

dicated in the table below.

For boilers with front flue passes 13)(Fig. 11) or flame inversion

chambers, a protection in refractory material 11) must be insert-

ed between the boiler refractory 12) and the blast tube 10).

This protection must not compromise the extraction of the blast

tube. See Fig. 11.

For boilers with a water-cooled frontal, a refractory lining is not

necessary 11)-12)(Fig. 11) unless expressly requested by the

boiler manufacturer.

Tab. L

Model

Short blast tube

Long blast tube

(with kit)

RS 70/E

9

27/32“

15

5/32“

RS 100/E

9

27/32“

15

5/32“

RS 130/E

11

1/32“

16

11/32“

Fig. 10

D455

inch

A

B

C

RS 70/E

7

9/32“

10

13/16“

- 12

25/32“

1/2 W

RS 100/E

7

9/32“

10

13/16“

- 12

25/32“

1/2 W

RS 130/E

7

21/32“

10

13/16“

- 12

25/32“

1/2 W

15

5

3

4

2

1

3

14

9

12

11

8

10

13

13

4 "

Fig. 11

D9278