20089637

28

GB

Start-up, calibration and operation of the burner

6.6

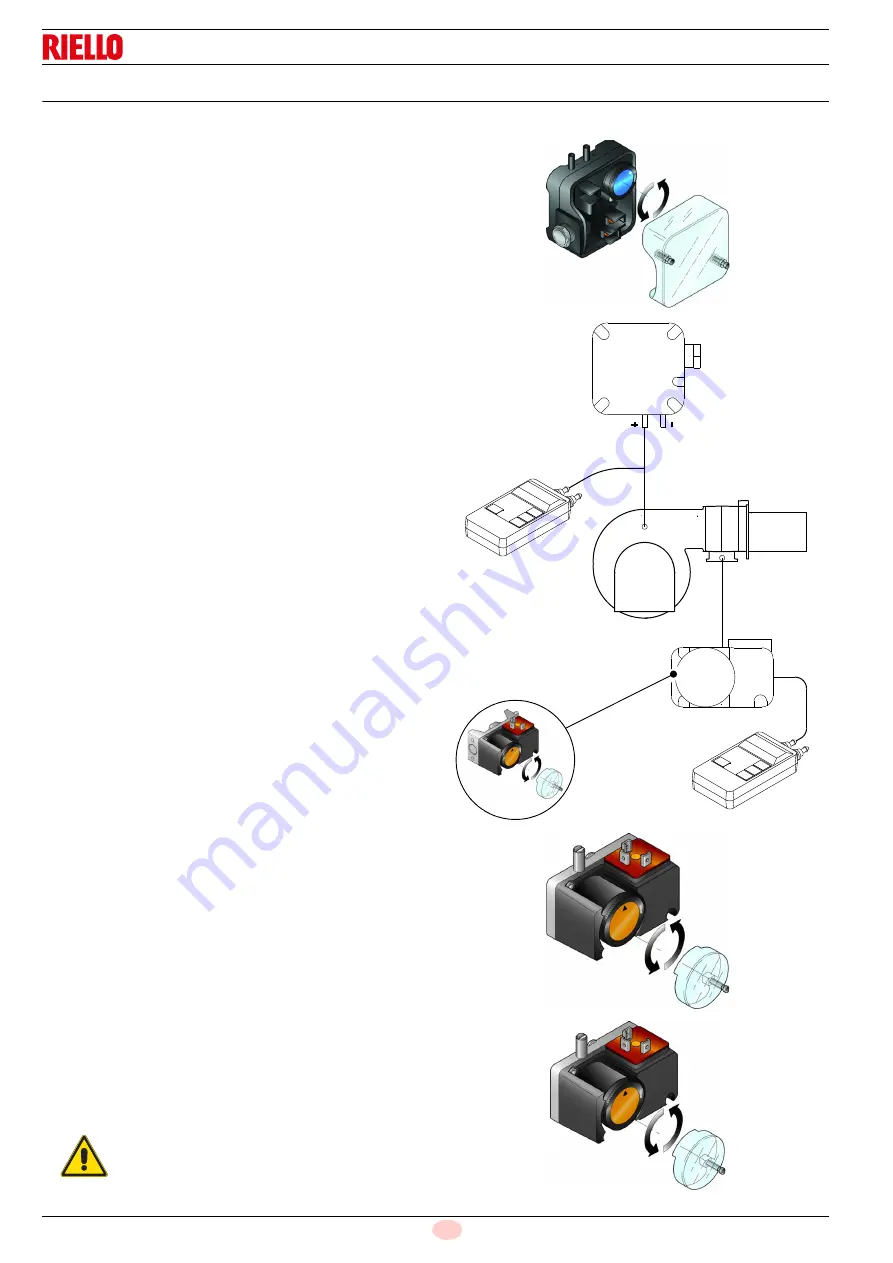

Pressure switch adjustment

6.6.1

Air pressure switch - check CO

Adjust the air pressure switch after performing all other burner

adjustments with the air pressure switch set to the start of the

scale (Fig. 31).

With the burner operating at MIN output, insert a combustion

analyser in the stack, slowly close the suction inlet of the fan (for

example, with a piece of cardboard) until the CO value does not

exceed 100 ppm.

Slowly turn the appropriate knob clockwise until the burner goes

into lockout.

Check the indication of the arrow pointing upwards on the gradu-

ated scale.

Turn the knob clockwise again, until the value shown on the grad-

uated scale corresponds with the arrow pointing downwards, and

so recovering the hysteresis of the pressure switch (shown by the

white mark on a blue background, between the two arrows). Now

check the correct start-up of the burner.

If the burner locks out again, turn the knob anticlockwise a little

bit more.

6.6.2

Maximum gas pressure switch

Adjust the maximum gas pressure switch (Fig. 32) after making

all other burner adjustments with the maximum gas pressure

switch set to the end of the scale.

To calibrate the maximum gas pressure switch, open the tap and

then connect a pressure gauge to its pressure test point.

The maximum gas pressure switch must be regulated to a value

no higher than 30% of the measurement read on the gauge when

the burner is working at maximum output.

After making the adjustment, remove the pressure gauge and

close the tap.

6.6.3

Minimum gas pressure switch

The purpose of the minimum gas pressure switch is to prevent

the burner from operating in an unsuitable way due to too low gas

pressure.

Adjust the minimum gas pressure switch (Fig. 33) after having

adjusted the burner, the gas valves and the gas train stabiliser.

With the burner operating at maximum output:

–

install a pressure gauge downstream of the gas train stabilis-

er (for example at the gas pressure test point on the burner

combustion head);

–

choke slowly the manual gas cock until the pressure gauge

detects a decrease in the pressure read of about 0.1 kPa

(1 mbar). In this phase, verify the CO value which must al-

ways be less than 100 mg/kWh (93 ppm).

–

Increase the adjustment of the gas pressure switch until it in-

tervenes, causing the burner shutdown;

–

remove the pressure gauge and close the cock of the gas

pressure test point used for the measurement;

–

open completely the manual gas cock.

6.6.4

PVP pressure switch kit

Adjust the pressure switch for the leak detection control (PVP kit)

(Fig. 34) according to the instructions supplied with the kit.

WARNING

1 kPa = 10 mbar

Fig. 31

D3854

PGM

PA

D3856

20181543

Fig. 32

Fig. 33

D3855

Fig. 34

D3855

Summary of Contents for RS 1300/EV BLU

Page 2: ...Translation of the original instructions ...

Page 40: ...20089637 38 GB Appendix Electrical panel layout ...

Page 41: ...39 20089637 GB Appendix Electrical panel layout ...

Page 43: ...41 20089637 GB Appendix Electrical panel layout ...

Page 44: ...20089637 42 GB Appendix Electrical panel layout 0 1 1 1 ...

Page 45: ...43 20089637 GB Appendix Electrical panel layout 0 1 0 ...

Page 46: ...20089637 44 GB Appendix Electrical panel layout 0 1 1 1 2 1 3 1 1 1 1 1 1 1 41 4 4 1 1 2 1 ...

Page 47: ...45 20089637 GB Appendix Electrical panel layout 0 0 0 1 0 2 0 0 0 0 0 0 0 30 3 3 0 0 1 0 4 ...

Page 48: ...20089637 46 GB Appendix Electrical panel layout 0 0 1 2 0 0 3 3 3 0 1 4 ...

Page 53: ......

Page 54: ......

Page 55: ......