20068118

40

GB

Start-up, calibration and operation of the burner

The control box will automatically report the same values set at

the points “

P0

” and “

P1

” to points “

P2

” to “

P8

”.

Press the key “

+

” until point “

P9

” has been reached.

Once “

P9

” has been reached wait until the display visualises the

flashing indictor “

P9

” proposing the same settings as point “

P0

”.

Now it is possible to change this value to attain the desired max-

imum operating power.

If the gas pressure is too low, despite opening the gas servomotor

to the maximum 90°, it is necessary to use the stabiliser of the

gas valve.

After adjusting point “

P9

keep the key “

+

” pressed for about 5 sec-

onds, the display shows “

CALC

” for a few seconds.

The control box will automatically calculate the points from “

P8

”

to “

P2

”, distributing them in a line. These are theoretical and must

be checked.

Check that the settings of point “

P8

” are adequate.

If not, modify the point.

Proceed in sequence, with the button “

-

” , up to point “

P1

”.

It is possible to modify point “

P1

” to obtain a different minimum

modulation point to the ignition point (“

P0

”).

During the adjustment of each point, work on the air and gas ser-

vomotors, without modifying the position of the gas valve stabilis-

er.

Halfway through the procedure (i.e. around point

P4

or

P5

), you

are advised to measure the gas delivery and check that the out-

put is about 50% of the maximum output.

If this is not the case, work also on the gas valve stabiliser: in this

case however, it is necessary to revise the calibrations of all the

points previously set.

Once the calibration of point “

P1

” is finished, confirm by simulta-

neously pressing keys “

+

” and “

-

” (

ESC

): the parameter “

546

” ap-

pears.

If you want to make the burner work on the entire modulation

curve, press the “

+

” and “

-

” (

ESC

) keys simultaneously: in this

way, parameter “

546

” will automatically be assigned the value of

100% and parameter “

545

” will have a value of 20%.

If you want to make the burner work on just a part of the modula-

tion curve, modify parameters “

546

” and “

545

” according to the

"Parameter modification procedure"

Simultaneously press the keys “

+

” and “

-

” (

ESC

) twice, the dis-

play will show the position of the current load.

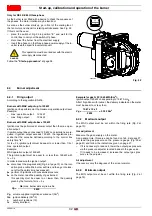

Factory settings

Tab. O

IMPORTANT

The purpose is to reach the point “

P9

” to adjust/fix

the maximum operating power.

IMPORTANT

Before moving on from one point to the next, wait

for the servomotors to reach the position visual-

ised on the display.

D90

4

1

h min s

%

V

P

Point of the curve

Burner

RS 25/E BLU

RS 35/E BLU

P0

air

16°

13°

gas

20°

20°

WARNING

it is nec-

essary to carry out a

, which is used to

memorise the parameters and the data in the con-

trol box inside the RDI21 display …

This operation allows the parameters and the

points of the modulation curve to be restored in

case of problems.

It is advisable to perform a backup every time that

a parameter is changed!

For the procedure refer to the section

D9

014

P

h

V

min s

%

ESC

Summary of Contents for RS 25/E BLU Series

Page 2: ...Translation of the original instructions...

Page 65: ...63 20068118 GB Appendix Electrical panel layout RS 25 E BLU...

Page 66: ...20068118 64 GB Appendix Electrical panel layout RS 35 E BLU...

Page 67: ...65 20068118 GB Appendix Electrical panel layout RS 35 E BLU 3Ph...

Page 68: ...20068118 66 GB Appendix Electrical panel layout RS 25 35 E BLU...

Page 69: ...67 20068118 GB Appendix Electrical panel layout RS 35 E BLU 3Ph...

Page 70: ...20068118 68 GB Appendix Electrical panel layout...

Page 71: ...69 20068118 GB Appendix Electrical panel layout...

Page 72: ...20068118 70 GB Appendix Electrical panel layout...

Page 73: ...71 20068118 GB Appendix Electrical panel layout...

Page 75: ......