12

NOTE

The servomotor follows the adjustment of cam

III only when the angle of the cam is reduced. If

it is necessary to increase the angle of the cam,

you must first increase the angle of the servo-

motor by means of the “output increase” key,

then increase the angle of cam III, and finally

bring the servomotor to the position of MIN out-

put, with the “output reduction” key.

If it is necessary to adjust cam III, remove the

cover 1) (inserted with a trigger catch, as indi-

cated in fig. (B), extract the special key 2) from

inside, and insert it in the notch of cam III.

Adjustment of air delivery

Progressively adjust the starting profile of cam

4)(A) by turning the screws working through the

access hole 6)(A). It is preferable not to turn the

first screw since this is used to set the air

damper to its fully closed position.

2 - MAX. OUTPUT

Max. output of the burner must be set within the

firing rate range shown on page 5.

In the above description, we left the burner

switched on, working at MIN output. Now press

the button 2)(A)p.11 “output increase”, and keep

it pressed until the servomotor has opened the

air damper and the gas butterfly valve at 90°.

Adjusting gas delivery

Measure the gas delivery at the meter.

As a general rule, it can be seen from the table

on page 6, just read the gas pressure on the

pressure gauge, see fig.(C)p.10, and follow the

indications given on page 6.

- If delivery needs to be reduced, diminish out-

let gas pressure and, if it is already very low,

slightly close adjustment valve VR.

- If delivery needs to be increased, increase

outlet gas pressure.

Adjustment of air delivery

Progressively adjust the end profile of cam 4)(A)

by turning the cam adjustment screws as they

appear through the access opening 6)(A).

- Turn the screws clockwise to increase air

delivery.

- Turn the screws anti-clockwise to reduce air

delivery.

3 - INTERMEDIATE OUTPUTS

Adjusting gas delivery

No adjustment of gas delivery is required.

Adjustment of air delivery

Press the key 2)(A)p.11 “output increase” a little

so that a new screw 5)(A) appears in the open-

ing 6)(A). Adjust it until optimal combustion is

obtained. Proceed in the same way with the

other screws.

Take care that the cam profile variation is pro-

gressive.

Switch the burner off with the switch 1)(A)p.11.

Release the variable profile cam by putting the

servomotor slot 2)(A) in a vertical position and

check more than once, rotating the cam forward

and backward by hand, that the movement is

soft and smooth, without sticking.

As far as is possible, try not to move those

screws at the ends of the cam that were previ-

ously adjusted for the opening of the air damper

to MAX and MIN output.

NOTE

Once you have finished adjusting outputs MAX -

MIN - INTERMEDIATE, check ignition once

again: noise emission at this stage must be

identical to the following stage of operation. If

you notice any sign of pulsations, reduce the

ignition stage delivery.

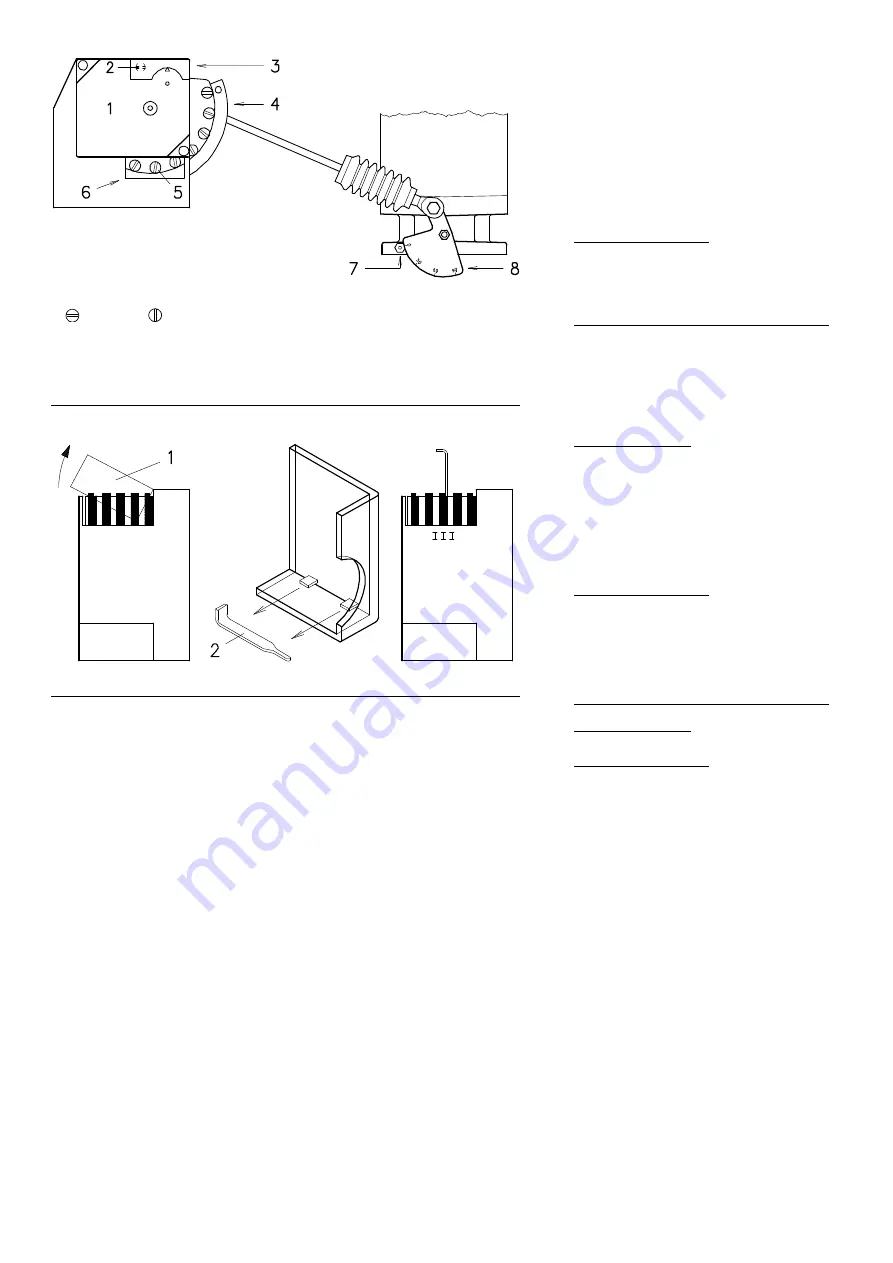

(A)

(B)

D518

D793

1 Servomotor

2

Constraint /

Release of cam 4

3 Cam cover

4 Variable profile cam

5 Screws for adjusting the variable profile

6 Slit to access the screws 5

7 Index of graduated sector 8

8 Gas butterfly valve graduated sector