16

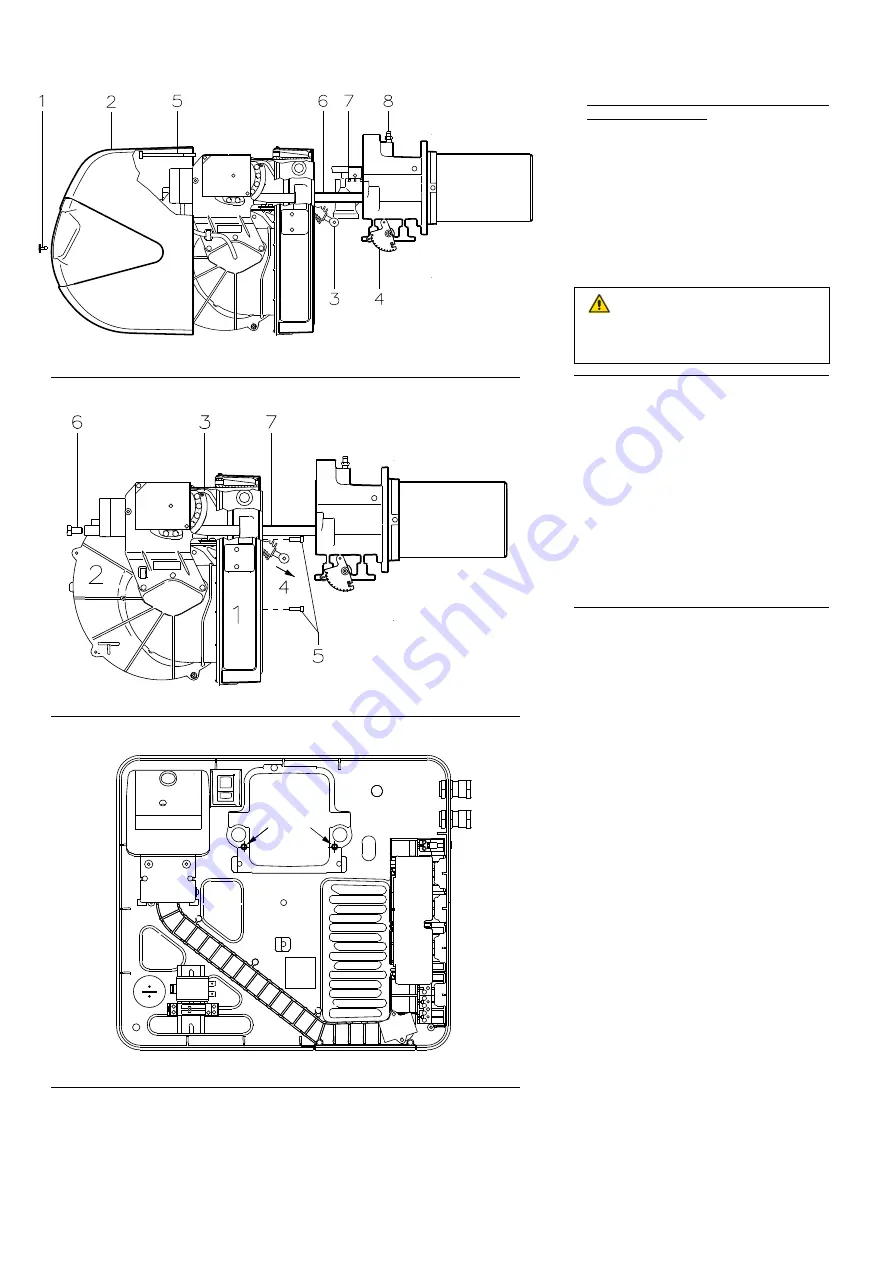

TO OPEN THE BURNER (A):

- Switch off the electrical power.

- Remove the screw 1) and pull out the hood

2).

- Disengage the articulated coupling 3) from

the graduated sector 4).

- Remove the screw 5) only with the long head

models; pull the burner back on the guides 6)

for about 100mm. Disconnect the probe and

electrode leads and then pull the burner fully

back.

Now extract the gas distributor 7) after having

removed the screw 8).

Remove the screws 2)(B)p.7 and tighten the two

extensions 25)(A)p.4 supplied with the burner.

Retighten the two screws 2)(B)p.7 on the termi-

nal of the extensions.

TO CLOSE THE BURNER (A):

- Push the burner up to approximately 100 mm

from the pipe coupling.

- Reconnect the leads and slide in the burner

until it comes to a stop.

- Replace the screw 5) and carefully pull the

probe and electrode cables outwards until

they are slightly taut.

- Re-couple the articulated coupling 3) to the

graduated sector 4).

- In the long head models, unscrew the exten-

sions and reposition them in the appropriate

space; tighten the screws to the guides

2)(C)p.7.

- Reposition the hood 2) and fix with the

screw 1).

SWITCHBOARD MAINTENANCE

If it is necessary to carry out maintenance on the

switchboard 1)(B), it is possible to remove only

the fan unit 2)(B), to allow improved access to

the electrical components.

With the burner open as in fig. (A), unhook the

tie-rod 3)(B), removing the screw on the variable

profile cam, and extract it from the tip 4)(B).

At this point, disconnect the cables relating to

the air pressure switch, the servomotor and fan

motor.

Remove the 3 screws 5)(B) positioned on the

protective cover.

Removing the 2 screws 6)(B), it is possible to

unthread the fan unit 2)(B) from the guides

7)(B).

Finally, you can use 2 of the 3 screws 5)(B) to fix

the electrical switchboard to the pipe coupling,

in the points indicated in fig. (C), and then carry

out the maintenance operations.

ATTENTION

Proceed with the assembly of the

inner part of the combustion head,

tightening the screw 8)(A) with a tight-

ening torque of

4 ÷ 6 Nm

.

(A)

OPENING THE BURNER

D3846

(B)

D3876

(C)

D3877