20159324

20

GB

Installation

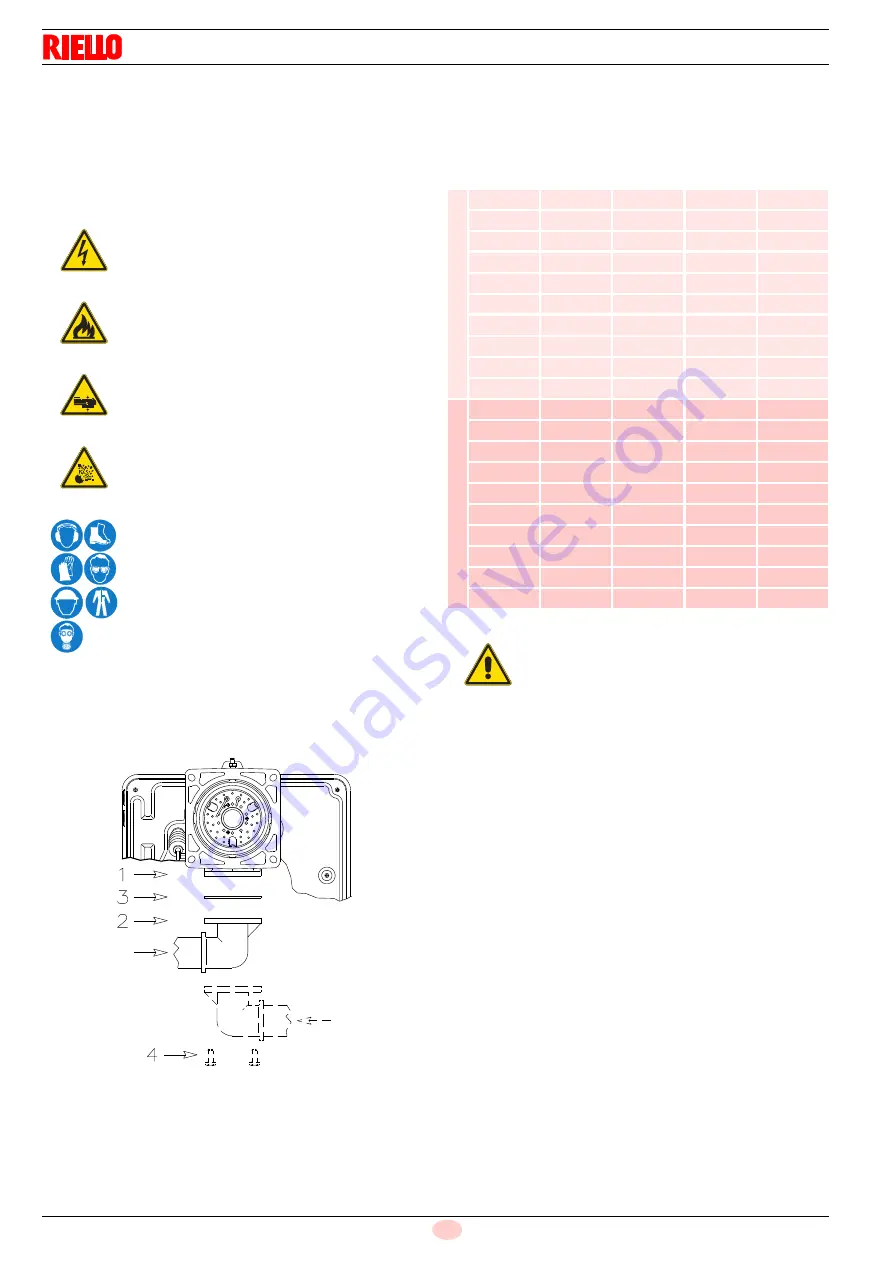

5.9.2

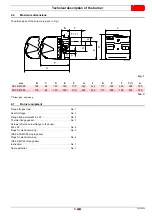

Gas train

Type-approved in accordance with EN 676 and supplied

separately from the burner.

To select the correct gas train model, refer to the manual "Burner-

gas train combination" supplied with the unit.

5.9.3

Gas train installation

The gas train must be connected to the gas connection 1)

(Fig. 21), using the flange 2), the gasket 3) and the screws 4)

supplied with the burner.

The train can enter the burner from the right or left side,

depending on which is the most convenient, see Fig. 21.

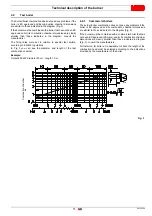

5.9.4

Gas pressure

Tab. F indicates the pressure drops of the combustion head and

gas butterfly valve, on the basis of the burner operating output.

Tab. F

The values shown in Tab. F refer to:

–

Natural gas G 20 NCV 9.45 kWh/Sm

3

(8.2 Mcal/Sm

3

)

–

Natural gas G 25 NCV 8.13 kWh/Sm

3

(7.0 Mcal/Sm

3

)

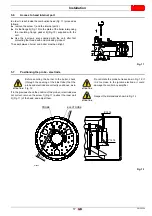

DANGER

Disconnect the electrical power using the main

switch.

Check that there are no gas leaks.

Pay attention when handling the train: danger of

crushing of limbs.

Make sure that the gas train is properly installed

by checking for any fuel leaks.

The operator must use the required equipment

during installation.

Fig. 21

D3839

kW

1

p (mbar)

2

p (mbar)

G 20

G 25

G 20

G 25

RS 25

/M C05

70

0.5

0.6

0.1

0.1

100

1.0

1.4

0.1

0.2

130

1.9

2.8

0.2

0.3

160

3.0

4.4

0.3

0.5

190

4.3

6.5

0.5

0.7

220

6.0

9.0

0.7

1.0

250

7.9

11.8

0.9

1.3

280

10.1

15.1

1.1

1.7

310

12.6

18.8

1.4

2.1

340

15.3

22.9

1.7

2.5

RS 35/M

C0

5

80

3.0

4.4

0.3

0.5

120

4.4

6.6

0.5

0.7

160

5.9

8.8

0.7

1.0

200

7.5

11.1

0.8

1.2

240

9.0

13.3

1.0

1.5

280

10.5

15.7

1.2

1.7

320

12.1

17.9

1.3

2.0

360

13.6

20.3

1.5

2.3

400

15.1

22.6

1.7

2.5

440

16.7

25.0

1.9

2.8

ATTENTION

Data of head thermal power and gas

pressure refer to operation with gas

butterfly valve fully open (90°).