21

20159324

GB

Installation

Column 1

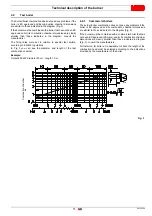

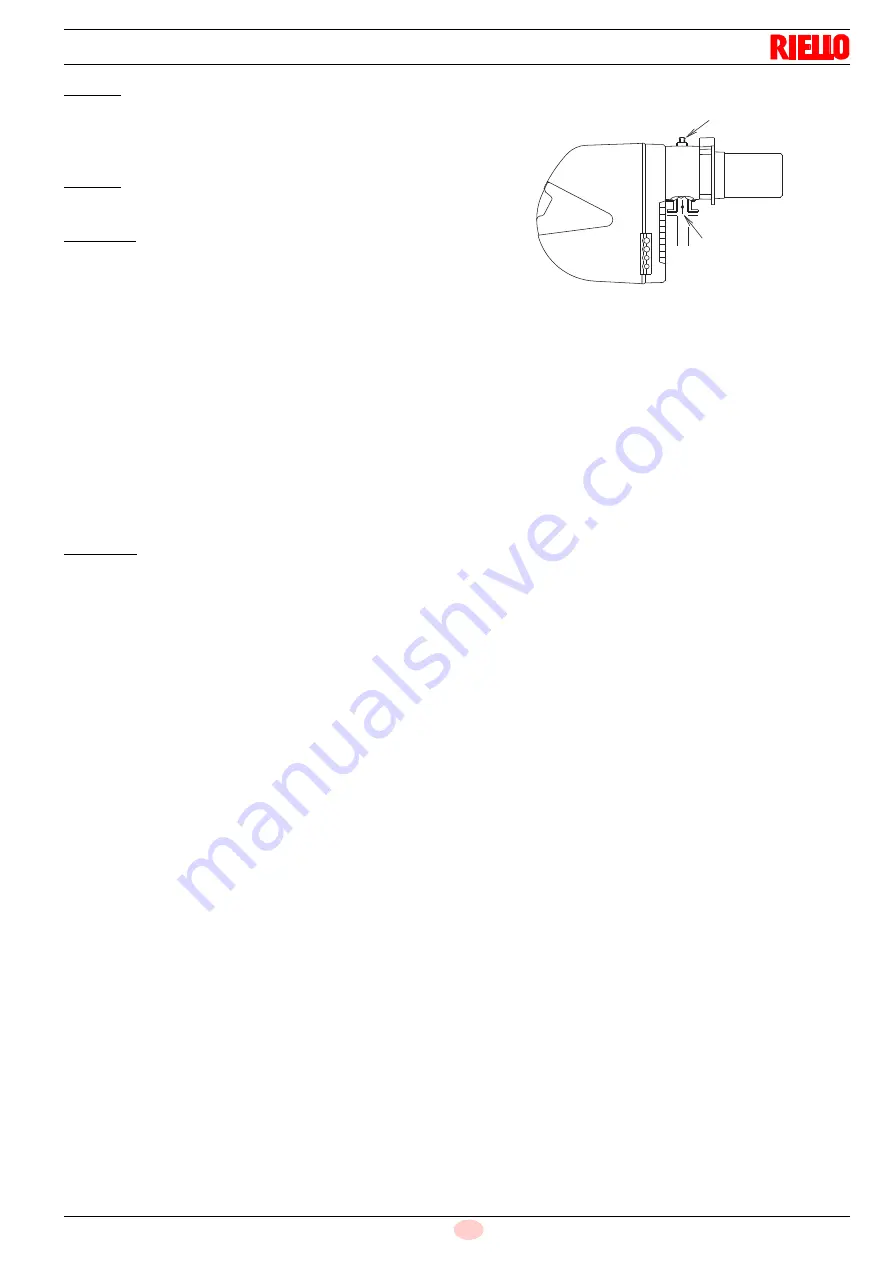

Combustion head pressure drop.

Gas pressure measured at test point 1)(Fig. 22), with:

•

combustion chamber at 0 mbar;

•

burner working at maximum output

Column 2

Pressure loss at gas butterfly valve 2)(Fig. 22) with maximum

opening: 90°.

To calculate the approximate output at which the burner operates

in the 2nd stage:

–

subtract the combustion chamber pressure from the gas

pressure measured at test point 1)(Fig. 22).

–

Find in Tab. F related to the burner concerned, the pressure

value closest to the result of the subtraction.

–

Read the corresponding output on the left.

Example - RS 35/M C05:

Maximum output operation

Natural gas G 20 NCV 9.45 kWh/Sm

3

Gas pressure at test point 1)(Fig. 22)

=

15.6 mbar

Pressure in combustion chamber

=

2.0 mbar

15.6 - 2.0

=

13.6 mbar

A pressure of 13.6 mbar, column 1, corresponds in table

RS 35/M C05 to output of 360 kW.

This value serves as a rough guide; the effective output must be

measured at the gas meter.

To calculate the required gas pressure at test point 1)(Fig. 22),

set the maximum modulating output required from the burner

operation:

–

find the nearest output value in the table Tab. F for the burner

in question.

–

read, on the right (column 1), the pressure at the test point 1)

(Fig. 22).

–

Add this value to the estimated pressure in combustion

chamber.

Example - RS 35/M C05:

Required burner maximum output operation: 360 kW

Natural gas G 20 NCV 9.45 kWh/Sm

3

Gas pressure at an output of 360 kW

=

13.6 mbar

Pressure in combustion chamber

=

2.0 mbar

13.6 + 2.0

=

15.6 mbar

pressure required at test point 1)(Fig. 22).

Fig. 22

2

1

S8738