20159324

22

GB

Installation

5.10

Electrical connections

Notes on safety for the electrical wiring

Notes:

•

the model RS 35/M C05 three phase leaves the factory with

an electrical supply setting of

400V

.

If

230V

power supply is used, change the motor connection

from star to delta and change the setting of the thermal relay

as well.

•

The burners RS 25-35/M C05 have been approved for

intermittent operation.

This means they should be compulsorily stopped at least

once every 24 hours to enable the control box to perform a

check of its own efficiency at start-up.

Normally, the stopping of the burner is guaranteed by the

boiler's thermostat/pressure switch.

If this is not the case, a time switch should be fitted in series

to IN to provide for burner shut-down at least once every 24

hours.

•

The RS 25-35/M C05 burners leave the factory fitted for two

stage operation and must therefore be fitted to the TR

thermostat/pressure switch.

If on the other hand you require a burner with single stage

operation, insert a jumper between clamps T6 - T7 of plug X4.

Modulating operation

If the output power regulator kit RWF or the converter 0...10V /

4...20mA is connected, in 3-point signal, the thermostat/pressure

switch TR must be removed (if the 4-pole socket becomes

unhooked, apply the supplied cover).

Using just the regulator RWF also remove the TL thermostat/

pressure switch.

Before carrying out any maintenance, cleaning or checking

operations:

Use flexible cables according to EN 60 335-1 Regulations:

•

if in PVC sheath, use at least H05 VV-F.

•

if in rubber sheath, use at least H05 RR-F.

All cables to be connected to the burner must be passed through

the cable grommets.

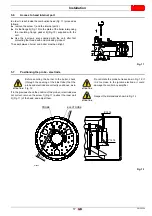

DANGER

The electrical wiring must be carried out with the electrical supply disconnected.

Electrical wiring must be made in accordance with the regulations currently in force in the country of destination

and by qualified personnel. Refer to the wiring diagrams.

The manufacturer declines all responsibility for modifications or connections different from those shown in the

wiring diagrams.

Check that the electrical supply of the burner corresponds to that shown on the identification label and in this

manual.

The electrical safety of the device is obtained only when it is correctly connected to an efficient earthing system,

made according to current standards. It is necessary to check this fundamental safety requirement. In the event of

doubt, have the electrical system checked by qualified personnel. Do not use the gas tubes as an earthing system

for electrical devices.

The electrical system must be suitable for the maximum power absorption of the device, as indicated on the label

and in the manual, checking in particular that the section of the cables is suitable for that level of power

absorption.

For the main power supply of the device from the electricity mains:

- do not use adapters, multiple sockets or extensions;

- use a multiple pole switch with at least a 3 mm gap between the contacts (over voltage category III), as

envisaged by the present safety standards.

Do not touch the device with wet or damp body parts and/or in bare feet.

Do not pull the electric cables.

ATTENTION

–

Do not invert the neutral with the phase in the

electrical supply line. An inversion would lead

to lockout due to ignition failure.

–

Replace the components only with original

spare parts.

DANGER

Disconnect the electrical supply from the burner

by means of the main system switch.

DANGER

Close the fuel shut-off valve.

DANGER

Avoid condensate, ice and water leaks from

forming.