25

20159324

GB

Start-up, calibration and operation of the burner

6.4

Burner ignition

Once the above steps are completed, the burner should ignite.

If the motor starts but the flame does not appear and the control

box goes into lockout, reset and wait for a new ignition attempt.

If ignition does not occur, it is possible that gas is not reaching the

combustion head within the safety time period of 3 seconds.

Therefore, it is necessary to increase gas ignition delivery.

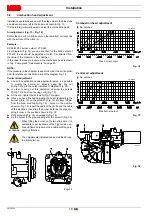

The arrival of gas to the sleeve is indicated by the U-type

pressure gauge (Fig. 25).

If the burner locks out again, refer to chapter "Faults - Possible

causes - Solutions” on page 35.

Once ignition has taken place, proceed with global calibration

operations.

6.5

Burner adjustment

The optimum adjustment of the burner requires an analysis of

flue gases at the boiler outlet.

Adjust successively:

Output upon ignition (minimum)

Max. burner output

Intermediate outputs between Min. and Max.

Air pressure switch

Minimum gas pressure switch

6.5.1

Determination of output upon ignition

(minimum)

According to the regulation EN 676.

Burners with MAX output up to 120kW

Ignition can be performed at the maximum operation output level.

Example:

•

max. operation output: 120 kW

•

max. ignition output: 120 kW

Burners with MAX output above 120kW

Ignition must be performed at a lower output than the max.

operation output.

If ignition output does not exceed 120 kW, no calculations are

required.

If ignition output exceeds 120 kW, the regulations prescribe that

the value be defined according to the control box safety time "ts":

for "ts" = 3s, ignition output must be equal to, or lower than, 1/3

of max. operation output.

Example:

MAX operation output of 450 kW.

The ignition output must be equal to, or less than,

150kW with ts = 3s

In order to measure the ignition output:

–

disconnect the plug-socket 24)(Fig. 4 on page 12) on the

ionisation probe cable (the burner will fire and then go into

lockout after the safety time has elapsed).

–

Perform 10 ignitions with consecutive lockouts.

–

Read, on the meter, the quantity of gas burned.

This quantity must be equal to, or lower than, the quantity

given by the formula, for ts = 3s:

Vg:

volume supplied in ignitions carried out (Sm

3

)

Qa:

ignition output (Sm

3

/h)

n:

number of ignitions (10)

ts

: safety time (sec)

Example

for gas G 20 (9.45 kWh/Sm

3

): ignition output 150 kW

corresponding to 15.87 Sm

3

/h.

After 10 ignitions with lockout, the output indicated on the meter

must be equal to, or less than:

6.5.2

Output upon ignition (minimum)

Min output must be selected within the firing rate range shown on

Fig. 2 on page 10.

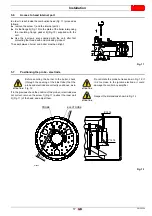

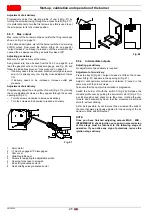

Press the button 2)(Fig. 26) “output reduction”, and keep it

pressed until the servomotor has closed the air damper and the

gas butterfly valve at 15° (adjustment made in the factory).

Adjusting gas delivery

Measure the gas delivery at the meter.

–

If it is necessary to reduce it, reduce slightly the angle of cam

III Fig. 28 on page 26

with small, regular movements, i.e.

bring it from an angle of 15° to 13° - 11°....

–

If it is necessary to increase it, press slightly the button

“output increase” 2)(Fig. 26) (open by 10-15° the gas butterfly

valve), increase the angle of cam III Fig. 28 on page 26 with

small, regular movements, i.e. bring it from an angle of 15° to

17° - 19°....

Then press the button “output reduction” until the servomotor

is in the position of minimum opening, and measure the gas

output.

Note

The servomotor follows the adjustment of cam III only when the

angle of the cam is reduced. If it is necessary to increase the

angle of the cam, you must first increase the angle of the

servomotor by means of the “output increase” key, then increase

the angle of cam III, and finally bring the servomotor to the

position of MIN output, with the “output reduction” key.

If it is necessary to adjust cam III Fig. 28, remove the cover

1)(Fig. 28) inserted with a trigger catch, as indicated in Fig. 28,

extract the special key 2)(Fig. 28) from inside, and insert it in the

notch of cam III.

ATTENTION

In the event the burner stops, in order to prevent

any damage to the installation, do not unblock the

burner more than twice in a row. If the burner

locks out for a third time, contact the customer

service.

DANGER

In the event there are further lockouts or faults

with the burner, the maintenance interventions

must only be carried out by qualified, authorised

personnel, in accordance with the contents of this

manual and in compliance with the standards and

regulations of current laws.

Vg =

3600

Qa

(max. burner output)

x n x ts

Vg =

3600

15.87 x 10 x 3

= 0.132 Sm

3