27

20159324

GB

Start-up, calibration and operation of the burner

6.6

Pressure switch adjustment

6.6.1

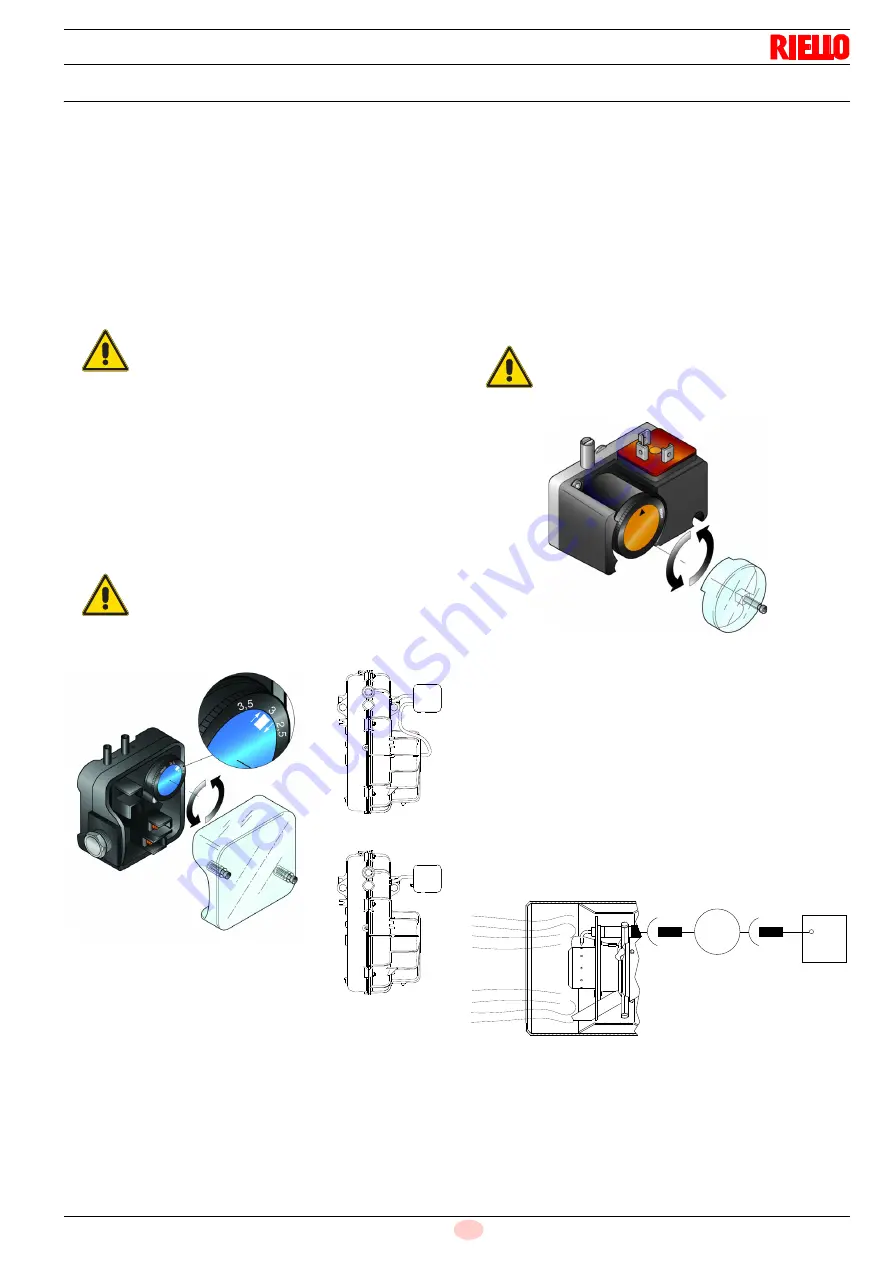

Air pressure switch

Adjust the air pressure switch after performing all other burner

adjustments with the air pressure switch set to the start of the

scale (Fig. 29).

With the burner operating in 1st stage, increase adjustment

pressure by slowly turning the relevant knob clockwise until the

burner locks out.

Then turn the knob anti-clockwise by about 20% of the set point

and repeat burner starting to ensure it is correct.

If the burner locks out again, turn the knob slightly anticlockwise.

The incorporated air pressure switch can work in a 'differential'

mode if connected with two pipes.

If a strong depression in the combustion chamber during the pre-

purging phase does not allow the air pressure switch to switch,

this can be obtained by applying a second tube between the air

pressure switch and the suction inlet of the fan.

In this way, the pressure switch will work in differential mode.

6.6.2

Gas minimum pressure switch

Adjust the minimum gas pressure switch after performing all the

other burner adjustments with the pressure switch set to the start

of the scale (Fig. 30).

With the burner operating in 2nd stage, increase adjustment

pressure by slowly turning the relevant knob clockwise until the

burner stops.

Then turn the knob anticlockwise by 0.2 kPa (2 mbar) and repeat

burner start-up to ensure it is operating regularly.

If the burner locks out again, turn the knob again anticlockwise by

0.1 kPa (1 mbar).

6.6.3

Flame presence check

The burner is fitted with an ionisation system to check that a

flame is present. The minimum current required for the control

box operation is 6

A.

The burner supplies a significantly higher current value, so that

no check is usually needed.

However, if it is necessary to measure the ionisation current,

disconnect the plug-socket 8)(Fig. 4 on page 12) on the

ionisation probe cable and insert a direct current microammeter

with a base scale of 100

A.

Carefully check polarities.

ATTENTION

As a rule, the air pressure switch must limit the CO

in the fumes to less than 1% (10,000 ppm).

To check this, insert a combustion analyser into

the chimney, slowly close the fan suction inlet (for

example with cardboard) and check that the

burner locks out, before the CO in the fumes

exceeds 1%.

ATTENTION

The use of the air pressure switch with differential

operation is allowed only in industrial applications

and where rules enable the air pressure switch to

control only fan operation without any reference to

CO limit.

Fig. 29

D3842

D3951

ATTENTION

1 kPa = 10 mbar

Fig. 30

D3855

Fig. 31

RMG

10

D3843

µA