20159324

32

GB

Maintenance

7.1

Notes on safety for the maintenance

The periodic maintenance is essential for the good operation,

safety, yield and duration of the burner.

It allows you to reduce consumption and polluting emissions and

to keep the product in a reliable state over time.

Before carrying out any maintenance, cleaning or checking

operations:

7.2

Maintenance programme

7.2.1

Maintenance frequency

7.2.2

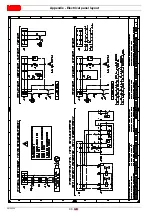

Safety test - with no gas supply

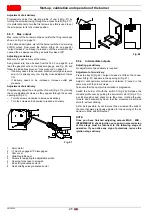

To perform commissioning in safety conditions, it is very

important to check correct wiring between gas valves and burner.

For this purpose, after checking that connections comply with the

burner wiring diagrams, it is necessary to carry out a start-up

cycle with gas cock closed (dry test).

1

The manual gas valve must be closed using the locking/

unlocking device (“Lock-out / tag out” procedure).

2

Ensure that burner limit electrical contacts are closed

3

Ensure that minimum gas pressure switch contact is closed

4

Try to start the burner.

The start-up cycle must occur according to the following steps:

–

Fan motor start-up for pre-purging

–

Gas valve leak detection control, if applicable.

–

Pre-purging completion

–

Achievement of the ignition point

–

Power supply of the ignition transformer

–

Supply of gas valves.

As gas is closed, the burner cannot ignite and its control box will

switch to stop or safety lockout condition.

The actual supply of gas valves can be checked by inserting a

tester; some valves are equipped with lights (or closing/opening

position indicators) that activate as soon as they are powered.

7.2.3

Checking and cleaning

Combustion head

Open the burner and make sure that all components of the

combustion head are in good condition, not deformed by the

high temperatures, free of impurities from the surroundings

and correctly positioned.

Gas filter

Change the gas filter when it is dirty.

Burner

Check that there are not excess wear or loosen screws.

The screws securing the electrical leads in the burner plugs

should also be fully tightened.

Clean the outside of the burner.

Clean and grease the adjustable profile of the cams.

Fan

Check to make sure that no dust has accumulated inside the fan

or on its impellers, as this condition will cause a reduction in the

air flow rate and provoke polluting combustion.

Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics

intact, especially: the flue gas temperature and combustion

chamber pressure.

Gas leaks

Make sure that there are no gas leaks on the pipe between the

gas meter and the burner.

7

Maintenance

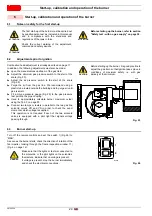

DANGER

The maintenance interventions and the calibration

of the burner must only be carried out by qualified,

authorised personnel, in accordance with the

contents of this manual and in compliance with the

standards and regulations of current laws.

DANGER

Disconnect the electrical supply from the burner

by means of the main system switch.

DANGER

Close the fuel shut-off valve.

Wait for the components in contact with heat

sources to cool down completely.

The gas combustion system should be checked at

least once a year by a representative of the

manufacturer or another specialised technician.

ATTENTION

IF POWER SUPPLY OF GAS VALVES

OCCURS IN UNEXPECTED MOMENTS, DO

NOT OPEN THE MANUAL VALVE,

DISCONNECT POWER SUPPLY, CHECK

WIRINGS, CORRECT THE ERRORS AND

CARRY OUT THE WHOLE TEST AGAIN.

The operator must use the required equipment

during maintenance.