20044359

18

Installation

4.8

Combustion head setting

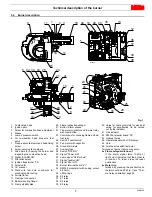

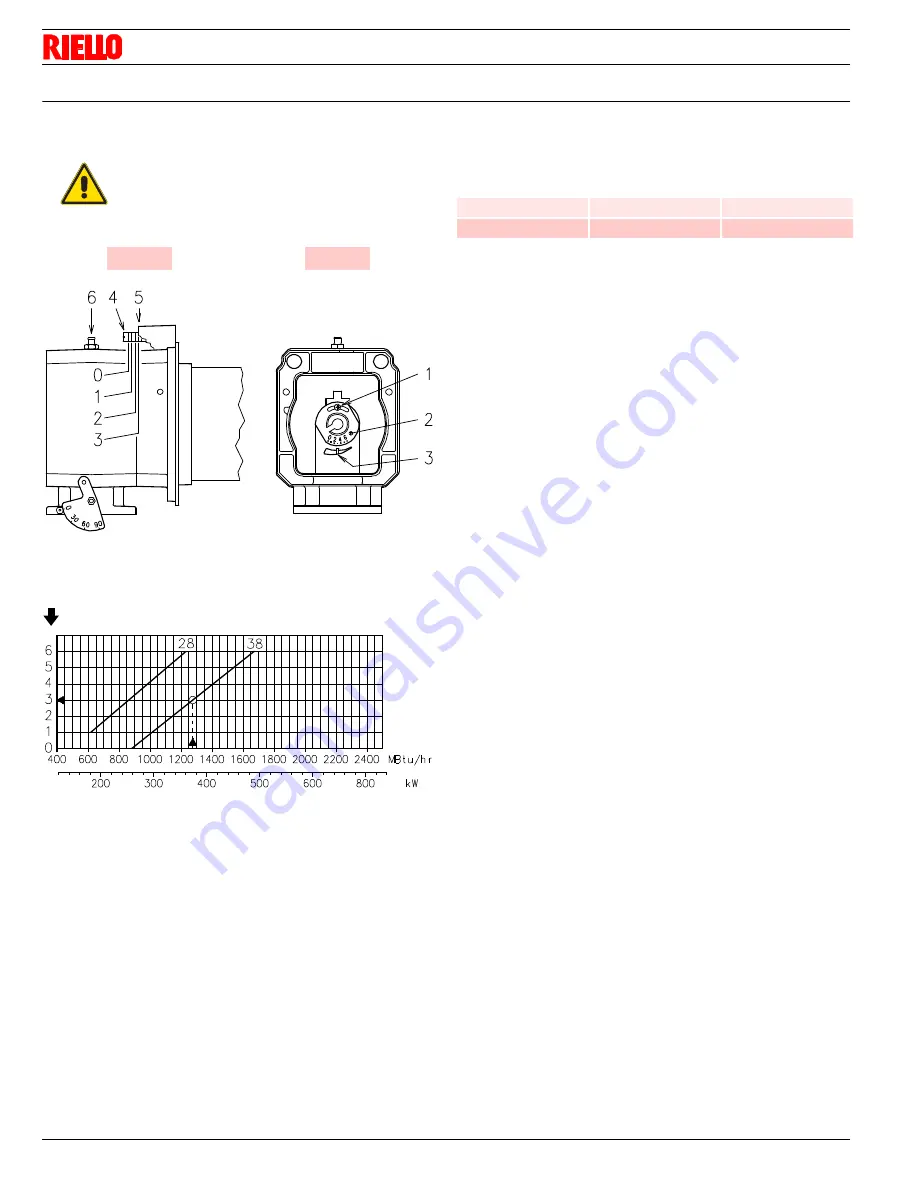

Installation operations are now at the stage where the blast tube

and sleeve are secured to the boiler as shown in Fig. 13.

4.8.1

Modulation minimum output

When the MIN output is within the value range given in Tab. F, the

gas ring 2) (Fig. 13) is adjusted to zero.

Tab. F

There are two possible cases:

A

The MIN burner output is not in the values of Tab. F

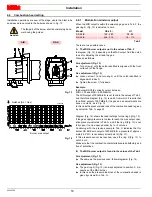

In diagram (Fig. 14), depending on the MAX output, find the notch

to use for adjusting the air and the gas.

Proceed as follows.

Air adjustment (Fig. 13)

Turn screw 4) until the notch identified is aligned with the front

surface 5) of the flange.

Gas adjustment (Fig. 13)

Loosen screw 1) and turn ring 2) until the notch identified is

aligned with index 3).

Tighten the screw 1) fully down.

Example:

the burner RS 28/E varies its output between:

MIN = 300 and MAX = 990 MBtu/hr.

The MIN output of 300 MBtu/hr is not found in the values of Tab. F

and therefore diagram (Fig. 14) is valid, from which it results that

for a MAX output of 990 MBtu/hr the gas and air adjustments are

done on notch 4, as in Fig. 13.

In this case the pressure load loss of the combustion head is given

by column A Tab. G, page 20.

Diagram (Fig. 14) shows the ideal settings for the ring 2)(Fig. 13).

If the gas supply pressure is too low to reach the max output oper-

ation pressure indicated in Tab. G, and if the ring 2)(Fig. 13) is not

fully open, it can be opened wider by 1 or 2 notches.

Continuing with the previous example, Tab. G indicates that for

burner RS 28/E with output of 990 MBtu/hr a pressure of approxi-

mately 2.2” WC is necessary at test point 6)(Fig. 13).

If this pressure cannot be reached, open the ring 2)(Fig. 13) to

notch 4 or 5.

Make sure that the combustion characteristics are satisfactory and

free of pulsations.

B

The MIN burner output is found in the values of the Tab. F

Air adjustment (Fig. 13)

The same as the previous case: follow diagramm (Fig. 14).

Gas adjustment (Fig. 13)

The gas ring 2)(Fig. 13) is always adjusted to position 0, irre-

spective of the MAX burner.

In this case the pressure load loss of the combustion heads is

given by column B in Tab. G.

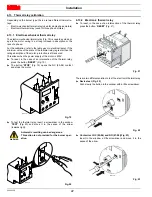

WARNING

The fan part of the burner shall be completely back-

ward using the guides.

Fig. 13

D2315

AIR

GAS

Fig. 14

20106409

Burner max output

Notches (Air = Gas)

Model

MBtu/hr

kW

RS 28/E

198 - 280

58 - 82

RS 38/E

266 - 375

78 - 110