20044359

30

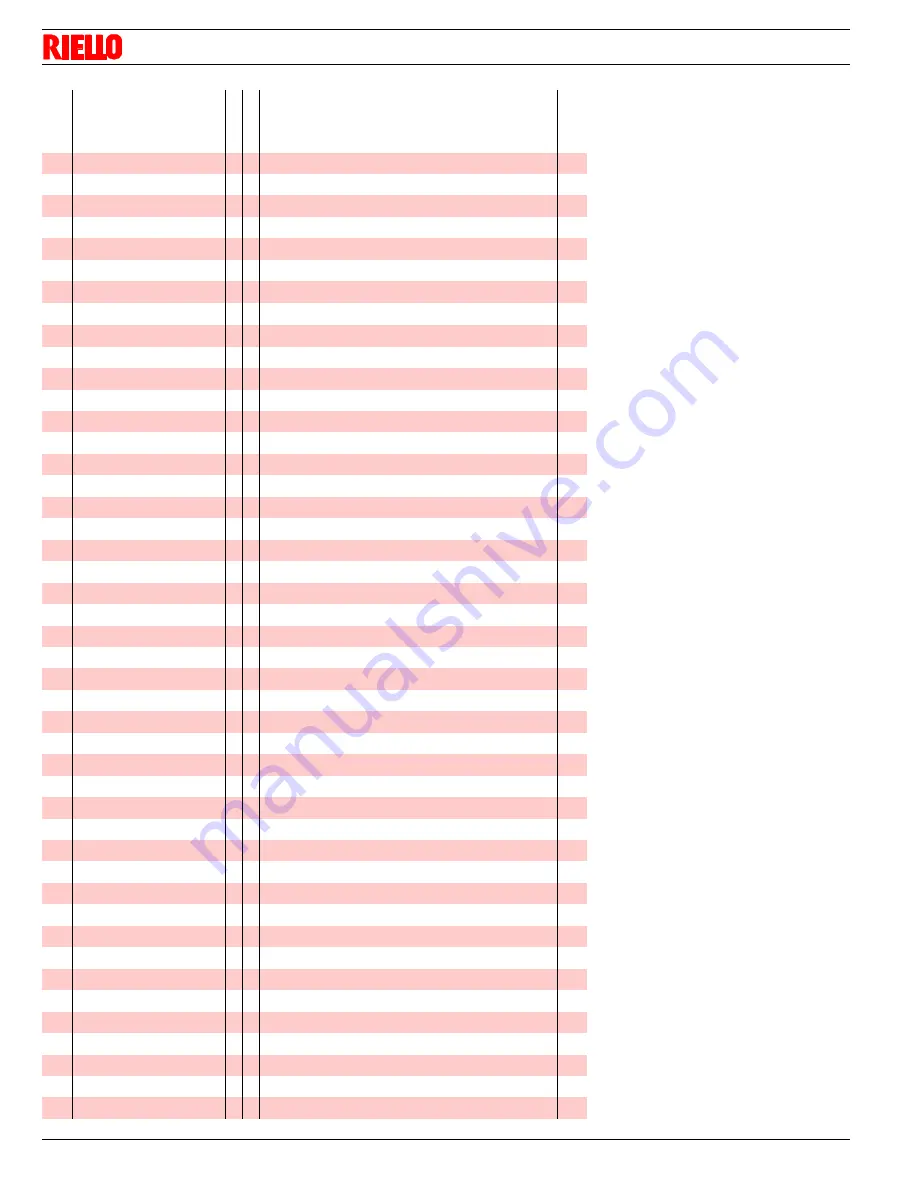

Appendix - Spare parts

N.

CODE

20

044216

20

105015

DESCRIPTION

1

3003760

•

FAN

A

1

3012986

•

FAN

A

2

3014194

• •

GRADUATE SECTOR

3

3003830

• •

SOUND DAMPING

4

20060108

• •

AIR INTAKE

5

20027023

• •

SWITCH

6

3012988

• •

CONDENSER

B

7

20010962

• •

BUTTON

C

8

20027013

• •

LIGHT SIGNAL

C

9

20027014

• •

LIGHT SIGNAL

C

10

3003763

• •

INSPECTION WINDOW

11

20026772

• •

BAR

C

12

20026773

• •

COVER

C

13

3013727

• •

SCREW

14

20026784

• •

VIEWING PORT AND SEAL

15

20026787

• •

PILOT TUBE

16

3013927

• •

CONTROL BOX

B

17

20027017

• •

CONTACTOR

C

18

20027018

• •

LIGHT SIGNAL

19

20027020

• •

LIGHT SIGNAL

20

3012956

• •

TRANSFORMER

B

21

20027021

• •

SWITCH

C

22

20008601

• •

SERVOMOTOR

B

23

3012993

• •

MOTOR

C

24

20027028

• •

SCREW

25

3003891

• •

CONNECTOR

C

26

3012948

• •

AIR PRESSURE SWITCH

A

27

3013926

• •

DISPLAY

28

3013940

• •

CONNECTORS

29

3003794

• •

ELECTRODE CONNECTOR

A

30

3003846

•

FERRULE

30

3003845

•

FERRULE

31

3003854

• •

ELBOW

32

3013129

• •

EXTERIOR TUBE

33

3003857

•

INTERIOR TUBE

33

3003859

•

INTERIOR TUBE

34

3012081

•

GAS HEAD

34

3012082

•

GAS HEAD

35

3012997

•

DISC

A

35

3012998

•

DISC

A

36

3003865

•

TUBE

36

3003866

•

TUBE

37

20026794

• •

PILOT CONNECTOR UNIT

38

3013136

• •

ELECTRODE

A

39

20027450

• •

U BOLT

*