20037075

36

GB

Start-up, calibration and operation of the burner

Further interfaces and computer communication functions for re-

mote control or integration in centrally supervised systems are

available according to the system’s configuration.

NOTE

The first start-up and all further operations concerning internal set-

tings of the control system or expansion of basic functions, are ac-

cessed with a password and are reserved for technical service

personnel specifically trained for internal programming of the in-

strument and for the specific application obtained with this burner.

The first start-up and curve synchronization manual is supplied with

the burner.

The complete manual for checking and setting all parameters will

be provided on application.

5.6

Final calibration of the pressure switches

5.6.1

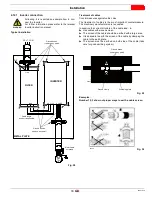

Air pressure switch

Adjust the air pressure switch (Fig. 34) after having performed all

other burner adjustments with the air pressure switch set to the

start of the scale.

With the burner operating at min. output, increase adjustment pres-

sure by slowly turning the relative dial clockwise until the burner

locks out.

Then turn the dial anti-clockwise by about 20% of the set point and

repeat burner starting to ensure it is correct.

If the burner locks out again, turn the dial anti-clockwise a little bit

more.

To check this, insert a combustion analyser into the chimney,

slowly close the fan suction inlet (for example with cardboard)

and check that the burner locks out, before the CO in the fumes

exceeds 1%.

5.6.2

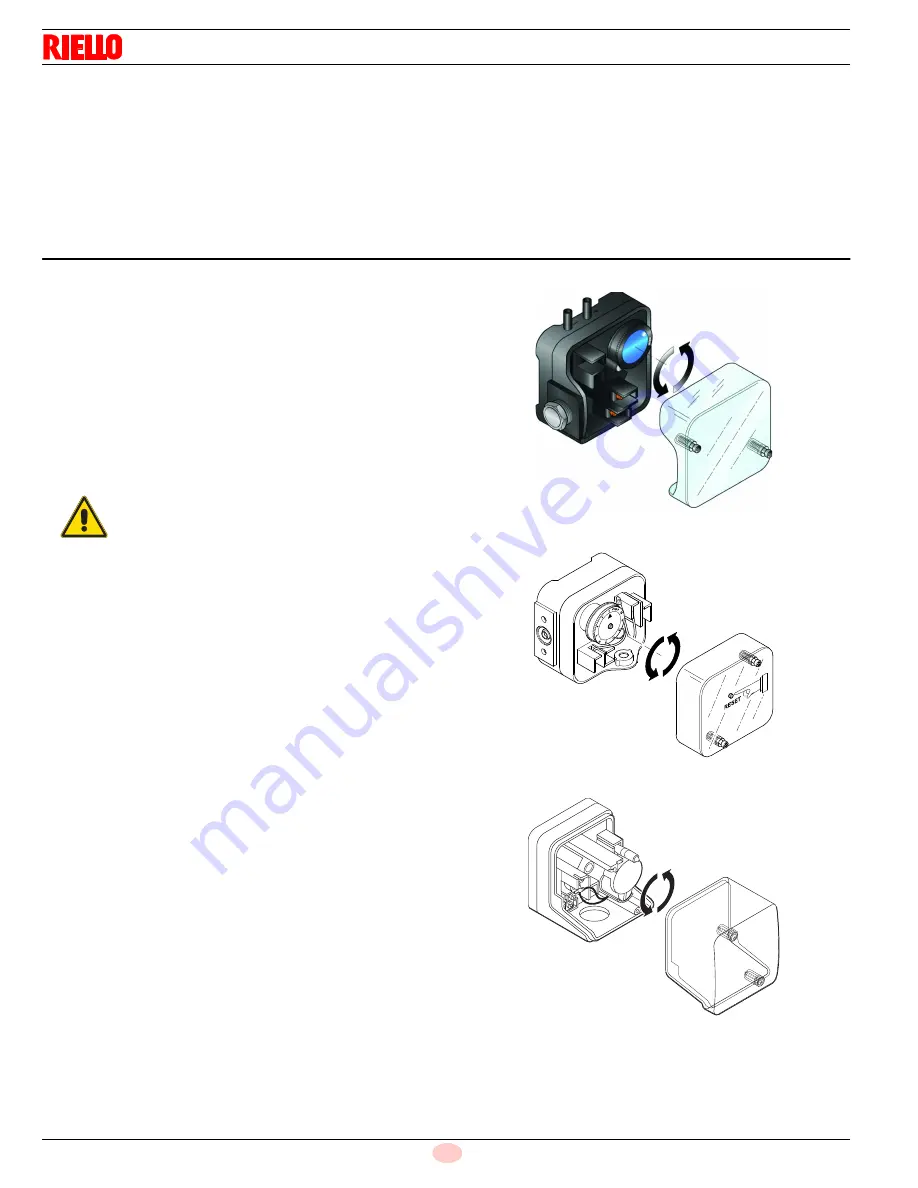

Maximum gas pressure switch

Adjust the maximum gas pressure switch (Fig. 35) after having per-

formed all other burner adjustments with the maximum gas pres-

sure switch set to the end of the scale.

With the burner operating at MAX output, reduce the adjustment

pressure by slowly turning the adjustment dial anticlockwise until

the burner locks out.

Then turn the dial clockwise by 0.8” WC and repeat burner firing.

If the burner locks out again, turn the dial again clockwise by

0.4” WC.

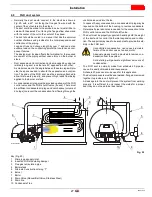

5.6.3

Minimum gas pressure switch

Adjust the minimum gas pressure switch (Fig. 36) after having per-

formed all the other burner adjustments with the pressure switch

set at the start of the scale.

With the burner operating at MAX output, increase adjustment

pressure by slowly turning the relative dial clockwise until the burn-

er locks out.

Then turn the dial anti-clockwise by 0.8” WC and repeat burner

starting to ensure it is uniform.

If the burner locks out again, turn the dial anti-clockwise again by

0.4” WC.

WARNING

As a rule, the air pressure switch must prevent the

formation of CO. To check this, insert a combustion

analyser into the chimney, slowly close the fan suc-

tion inlet (for example with cardboard) and check

that the burner locks out, before the CO in the

fumes exceeds 400 ppm.

Fig. 34

D3854

Fig. 35

D9272

Fig. 36

D9290

Summary of Contents for RS 300/EV FGR

Page 2: ......