20098208

24

GB

Start-up, calibration and operation of the burner

6.7.2

Maximum gas pressure switch

Adjust the maximum gas pressure switch (Fig. 31) after perform-

ing all other burner adjustments with the maximum gas pressure

switch set to the end of the scale.

With the burner operating at maximum output, lower adjustment

pressure by slowly turning the relative knob anticlockwise until

the burner locks out.

Turn the knob clockwise by 2 mbar and repeat the start-up of the

burner.

If the burner locks out again, turn the knob clockwise again by 1

mbar.

6.7.3

Minimum gas pressure switch

Adjust the minimum gas pressure switch (Fig. 32) after perform-

ing all the other burner adjustments with the pressure switch set

to the start of the scale.

With the burner operating at maximum output, increase adjust-

ment pressure by slowly turning the relative knob clockwise until

the burner locks out.

Then turn the knob anticlockwise by 2 mbar and repeat burner

start-up to ensure it is uniform.

If the burner locks out again, turn the knob anticlockwise again by

1 mbar.

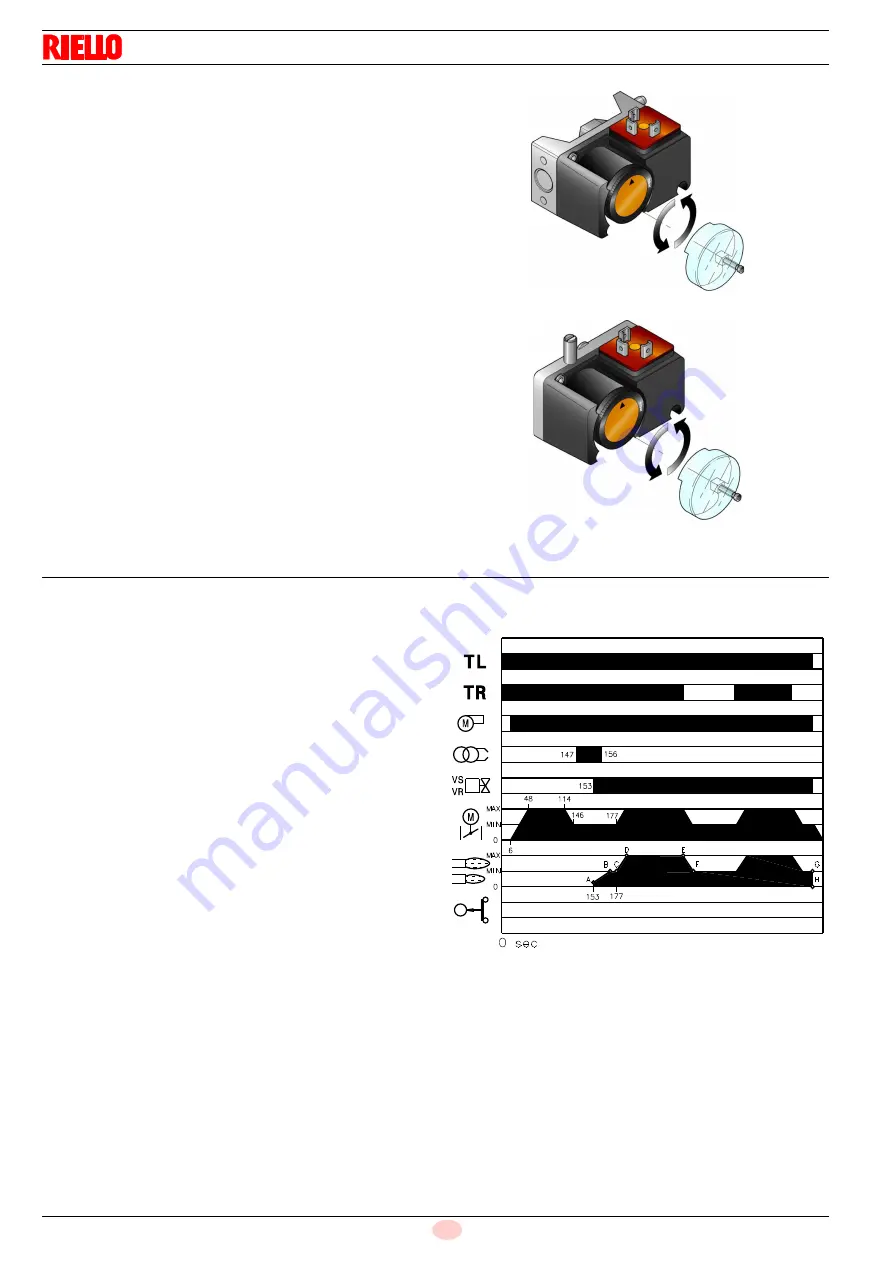

6.8

Operation sequence of the burner

6.8.1

Burner start-up

0s

TL thermostat/pressure switch closes.

6s

Fan motor starts up. Servomotor starts: 130 rotation to

the right, until contact is made on cam I.

48s

The air damper is positioned to MAX output.

48s

Pre-purging stage with MAX output air delivery.

Duration 66 seconds.

144s

The servomotor rotates to the left up to the angle set on

the cam II.

146s

The air damper and the gas butterfly valve adopt the MIN

output position (with cam II).

147s

Ignition electrode strikes a spark.

164s

The safety valve VS opens, along with the adjustment

valve VR (quick opening).

The flame is ignited at a low output level, point A

(Fig. 33). Output is then progressively increased, with the

valve opening slowly up to MIN output, point B (Fig. 33).

156s

The spark goes out.

177s

The control box start-up cycle ends.

Fig. 31

D3856

Fig. 32

D3855

Fig. 33

NORMAL IGNITION

20061660