20098208

26

GB

Maintenance

7.1

Notes on safety for the maintenance

The periodic maintenance is essential for the good operation,

safety, yield and duration of the burner.

It allows you to reduce consumption and polluting emissions and

to keep the product in a reliable state over time.

Before carrying out any maintenance, cleaning or checking oper-

ations:

7.2

Maintenance programme

7.2.1

Maintenance frequency

7.2.2

Checking and cleaning

Combustion

Carry out an analysis of the combustion discharge gases.

Significant differences with respect to the previous check indicate

the points where more care should be exercised during mainte-

nance.

Combustion head

Open the burner and make sure that all components of the

combustion head are in good condition, not deformed by the

high temperatures, free of impurities from the surroundings

and correctly positioned.

Burner

Check that there are not excess wear or loosen screws.

Clean the outside of the burner.

Fan

Check to make sure that no dust has accumulated inside the fan

or on its blades, as this condition will cause a reduction in the air

flow rate and provoke polluting combustion.

Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics in-

tact, especially the flue gas temperature and combustion cham-

ber pressure.

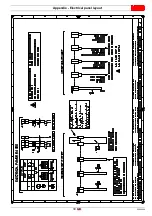

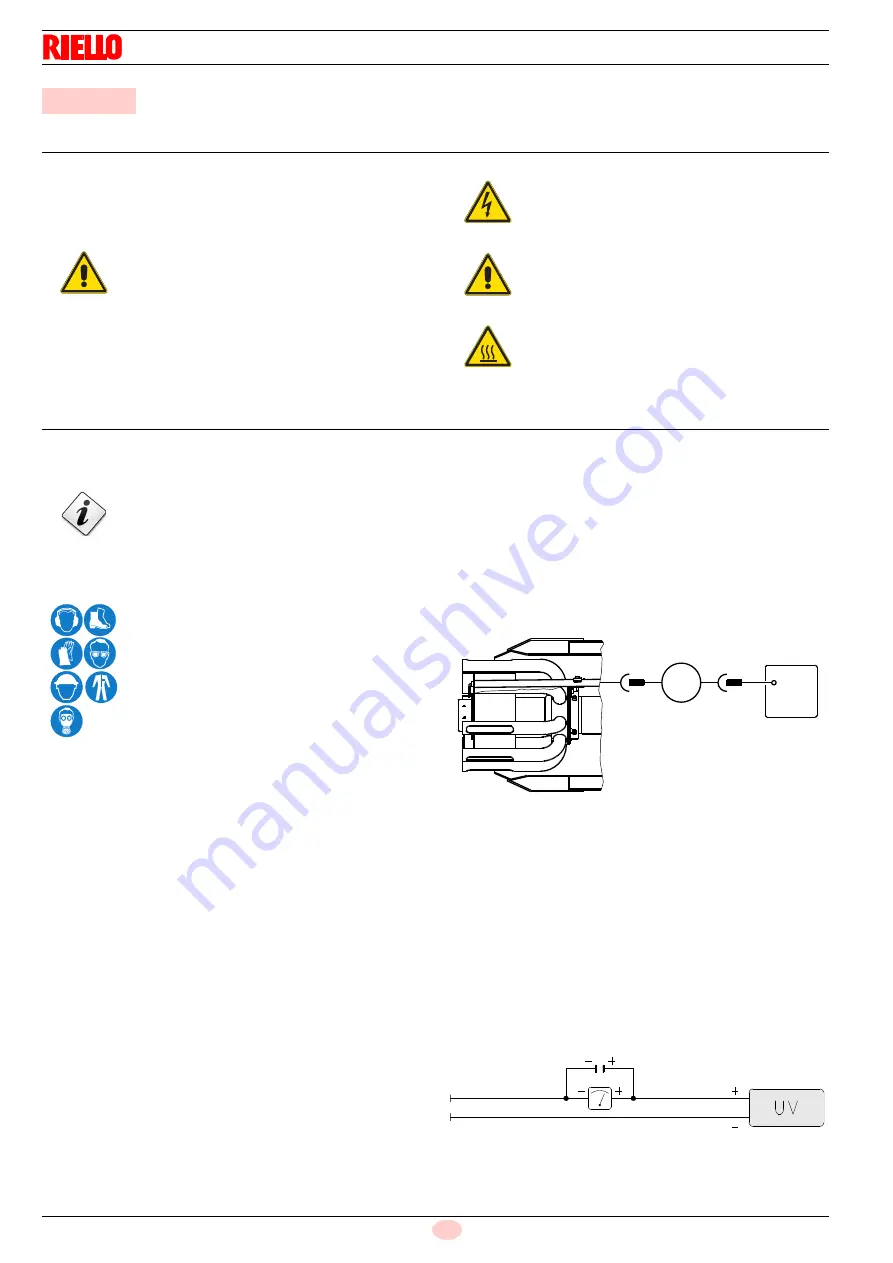

Flame presence check

The burner is fitted with an ionisation system to check that a

flame is present. The minimum current for control box operation

is 6 µA (Fig. 35).

The burner provides a much higher current, so controls are not

normally required. However, if it is necessary to measure the ion-

isation current, disconnect the plug-socket on the ionisation

probe cable and insert a direct current microammeter with a base

scale of 100 µA. Carefully check the polarities!

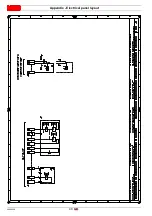

Electrical current to UV cell

Clean the glass cover from any dust that may have accumulated.

To remove the photocell, pull out outwards; it is only pressed in.

Minimum value for correct operation: 70 µA.

If the value is lower, it could be due to:

–

exhausted photocell

–

low voltage (lower than 187 V)

–

bad regulation of the burner

In order to measure the current, use a microammeter of 100 mA

c.c., connected in series to the photocell, as in the scheme, with

a capacitor of 100 mF - 1V c.c. at the same level of the instru-

ment.

7

Maintenance

DANGER

The maintenance interventions and the calibration

of the burner must only be carried out by qualified,

authorised personnel, in accordance with the con-

tents of this manual and in compliance with the

standards and regulations of current laws.

DANGER

Disconnect the electrical supply from the burner

by means of the main system switch.

DANGER

Close the fuel interception tap.

Wait for the components in contact with heat

sources to cool down completely.

The gas combustion system should be checked at

least once a year by a representative of the man-

ufacturer or another specialised technician.

The operator must use the required equipment

during maintenance.

Fig. 35

-

+

µ

A

D3097

Fig. 36

D1143