10

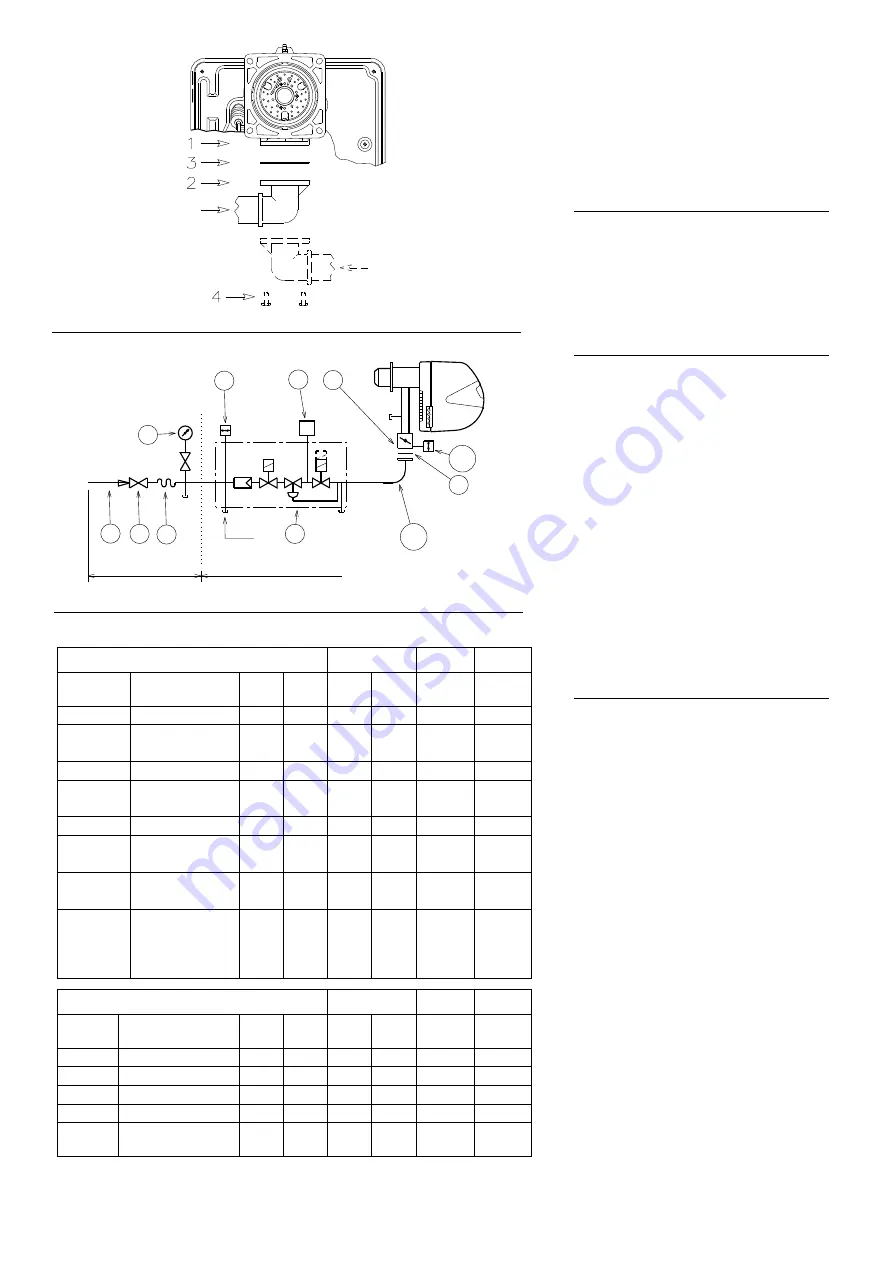

GAS FEEDING LINE

• The gas train must be connected to the gas

attachment 1)(A), using the flange 2), gasket

3) and screws 4) supplied with the burner.

• The gas train can enter the burner from the

right or left side, depending on which is the

most convenient, see fig. (A).

• The gas solenoids must be as close as possi-

ble to the burner, to ensure that the gas

reaches the combustion head within the safety

time of 3s.

GAS TRAIN (B)

Approved, together with the burner, according to

the regulation EN 676, and supplied separately

from the burner, with the code indicated in the

tables (C). It is possible to use the one-stage

gas train of table (C) up to a power of 550 kW,

limiting the ignition output according to the

standard, with the aid of only the brake, as spec-

ified on page 12.

KEY TO LAY-OUT (B)

1 - Gas input pipe

2 - Manual valve

3 - Vibration damping joint

4 - Pressure gauge with pushbutton cock

5 - Multibloc, including:

- filter (replaceable)

- one-stage or two-stage working valve

- pressure adjuster

6 - Minimum gas pressure switch

7 - Valve seal checking device.

In accordance with the standard EN 676,

gas valve leak detection control devices

are compulsory for burners with maximum

outputs of more than 1200 kW.

8 - Gasket

9 - Gas train/burner adaptor

P1 - Pressure at combustion head

P2 - Up-line pressure of valves/adjuster

L - Gas train supplied separately with the code

indicated in tables (C)

L1 - The responsibility of the installer

KEY TO LAY-OUT FOR TABELS (C)

C.T.= Checking device for gas valves seal:

- = Gas train without gas valve leak

detection control device; device that

can be ordered separately and

assembled subsequently (see Col-

umn 7).

= Train with seal checking device

already assembled.

= With this train the integrated leak

detection cannot be activated.

7

= VPS valve leak detection control device.

Supplied separately from gas train on

request.

9

= Gas train/burner adaptor.

Supplied separately from gas train on

request.

Note

See the accompanying instructions for the

adjustment of the gas train.

(A)

(B)

D3839

D8066

5

P2

P1

1 0

8

1

2

3

4

1 1

9

6

7

L 1

L

BURNERS AND RELATIVE GAS TRAINS APPROVED ACCORDING TO EN 676

*

Trains complete with 6-pin plug for connection to burner.

GAS TRAINS L (One-stage)

BURNER

7

9

Code

Model Ø

C.T.

RS

34/1

RS

44/1

Code

Code

3970602

MBC 120

3/4”

•

-

-

3000824

3970553

3970229

*

MB-DLE 407 S20

3/4”

-

•

-

3010123

3000824

3970599

MB-DLE 407 S52

3/4”

-

-

•

3010123

3000824

3970554

3970230

*

MB-DLE 410 S20

1”

-

•

•

3010123

3000824

3970258

MB-DLE 410 S52

1”1/4

•

3010123

3000824

3970144

3970231

*

MB-DLE 412 S20

1”1/4

-

•

•

3010123

-

3970180

3970232

*

MB-DLE 415 S20

1”1/2

-

•

•

3010123

-

3970181

3970233

*

3970182

3970234

*

MB-DLE 420 S20

2”

-

-

•

•

3010123

3010123

-

-

3000822

GAS TRAINS L (Two-stage)

BURNER

7

9

Code

Model

Ø

C.T.

RS

34/1

RS

44/1

Code

Code

3970046 MB-ZRDLE 407 S20

3/4”

-

•

-

3010123 3000824

3970079 MB-ZRDLE 410 S20

1”

-

•

•

3010123 3000824

3970152 MB-ZRDLE 412 S20

1”1/4

-

•

•

3010123

-

3970183 MB-ZRDLE 415 S20

1”1/2

-

•

•

3010123

-

3970184

3970185

MB-ZRDLE 420 S20

2”

-

•

•

•

•

3010123

-

-

3000822

(C)

Summary of Contents for RS 34/1 MZ

Page 22: ...LED LED 3...

Page 33: ...11 10 A B C 7 8 VR VS 4 18 A 3 C A C B D3855 D3854 D3841...

Page 37: ...15 TL TS...

Page 38: ...16 LED 10 3 1 3 1 3 2 3 17 3 1 3 LED 17 170V 1 3 3 LED 1 3 3 3 LED LED LED 10...

Page 40: ...18 LED 3 LED 3 RMG PC 3002719 2 1 0 4 2 0 8 6 2 8 LED 3 3 10...

Page 41: ...19 EN 60 335 1 RS 34 44 1 MZ 1 TL 7 2 6 3 TR 4 5 2 6 6A 6A RS 34 44 1 MZ 24 TL 24 D11833...

Page 43: ...21 RS 34 1 MZ...

Page 44: ...22 RS 44 1 MZ...

Page 45: ...23 RS 34 44 1 MZ...

Page 47: ......