Start-up, calibration and operation of the burner

23

20040407

GB

5.4

Burner firing

Having completed the checks indicated in the previous heading,

the pilot of the burner should fire.

If the motor starts but the flame does not appear and the flame

safeguard goes into lock-out, reset and wait for a new firing at-

tempt.

Pilot adjustment has been illustrated on page 13.

Having adjusted the pilot, reconnect the main valve and ignite the

main flame; it might require several attempts to purge the air from

the gas lines or to adjust the valve with little gas.

Once the burner has fired, now proceed with calibration operations.

5.5

Burner calibration

The optimum calibration of the burner requires an analysis of the

flue gases at the boiler outlet.

Adjust successively:

➤

Firing output

➤

Maximum burner output

➤

Minimum burner output

➤

Intermediate outputs between low and high fire

➤

Air pressure switch

➤

Minimum gas pressure switch

5.5.1

Firing output

Pilot adjustment has been illustrated on page 13.

5.5.2

Maximum burner output

Maximum output of the burner must be set within the “Firing rate”

range shown at page 8. In the above instructions we left the burner

running in MIN. output operation.

➤

Move the selector 24)(Fig. 6) in manual position.

➤

Move the selector 43)(Fig. 6) in position (+) (increase output)

and keep it until the servomotor has opened the air damper

and the gas butterfly valve to 90°.

Gas calibration

Measure the gas delivery at the meter.

A guideline indication can be calculated from the Tab. H, page 17,

simply read off the gas pressure on the U-type manometer

(Fig. 25), and follow the instructions at page 17.

➤

If delivery needs to be reduced, reduce outlet gas pressure

and, if it is already very low, slightly close adjustment valve.

➤

If delivery needs to be increased, increase outlet gas pres-

sure.

Adjusting air delivery

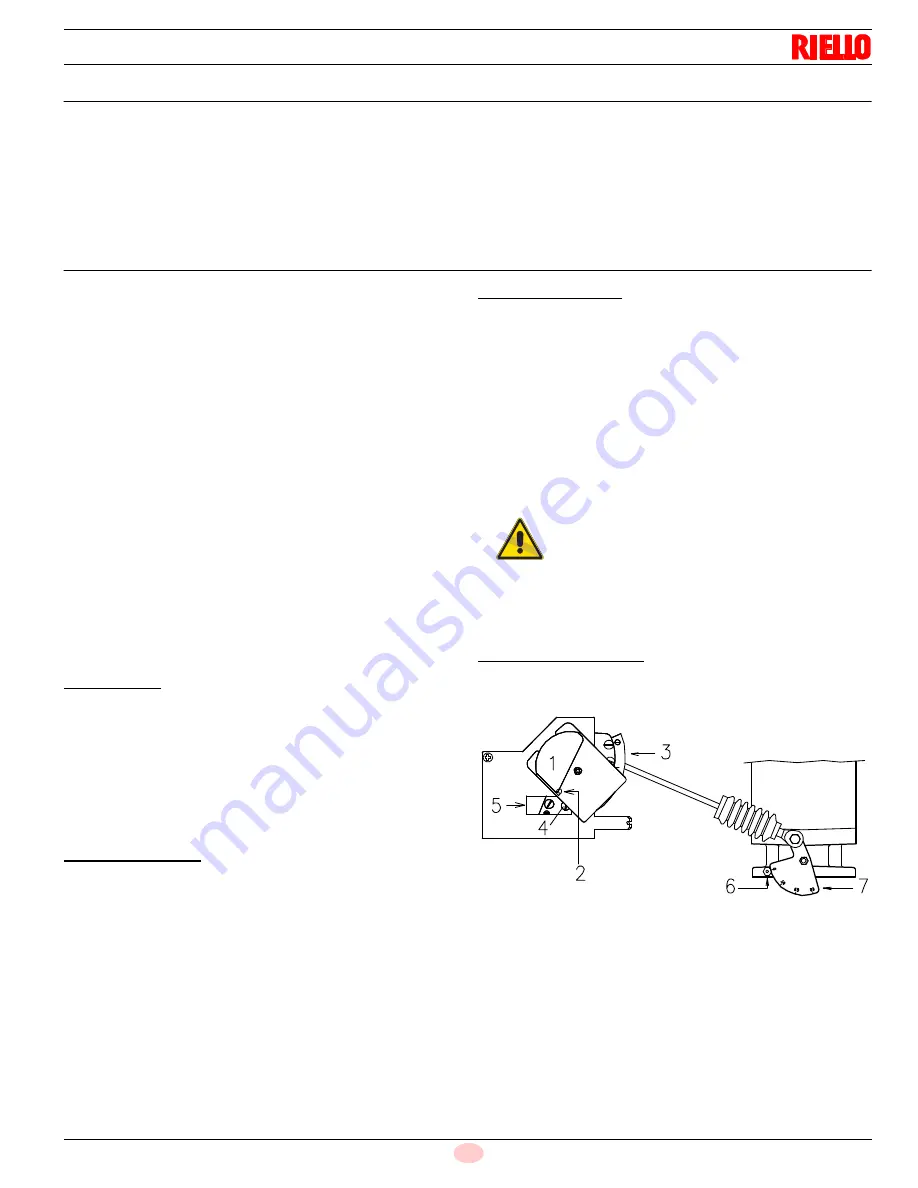

Progressively adjust the end profile of cam 4)(Fig. 27) by turning

the cam adjustment screws as they appear through the access

opening 6).

➤

Turn the screws clockwise to increase air delivery.

➤

Turn the screws counter-clockwise to reduce air delivery.

5.5.3

Minimum burner output

Minimum output must be selected within the “Firing rate” range

shown at page 8.

➤

Move the selector 24)(Fig. 6) in manual position.

➤

Move the selector 43)(Fig. 6) in position (-) (reduction output)

until the servomotor has closed the air damper and the gas

butterfly valve to 15° (factory set adjustment).

Adjusting gas delivery

Measure the delivery of gas from the gas meter.

➤

If this value is to be reduced, decrease the angle of orange

cam slightly by proceeding a little at a time until the angle is

changed from 15° to 13° or 11°....

➤

Move the selector 24)(Fig. 6) in manual position.

➤

If it has to be increased move the selector 43)(Fig. 6) in posi-

tion (+) (increase output) (i.e. open the gas butterfly valve by

10-15°), increase the orange cam angle with small successive

movements, i.e. take it from angle 15° to 17° - 19°....

➤

Move the selector 43)(Fig. 6) in position (-) (reduction output)

until the servomotor is taken to the minimum opening position

and measure the gas delivery.

Adjustment of air delivery

Progressively adjust the starting profile of cam 4)(Fig. 27) by turn-

ing the screws working throught the access hole 6).

Key (Fig. 27)

1

Servomotor

2

Lever, push to engage, push to release

3

Adjustable profile cam

4

Cam profile adjustment screws

5

Opening for access to screws 5

6

Index for graduated sector 8

7

Graduated sector for gas butterfly valve

WARNING

The servomotor follows the adjustment of cam only

when the cam angle is reduced.

If it is necessary to increase the cam angle, first in-

crease the servomotor angle with the switch “output

increase”, then increase the orange cam angle, and

at the end bring the servomotor back to the MIN out-

put position with the switch ”output decrease”.

Fig. 27

D2267