20008423

16

GB

Technical description of the burner

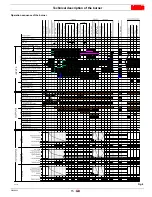

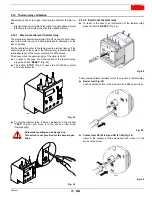

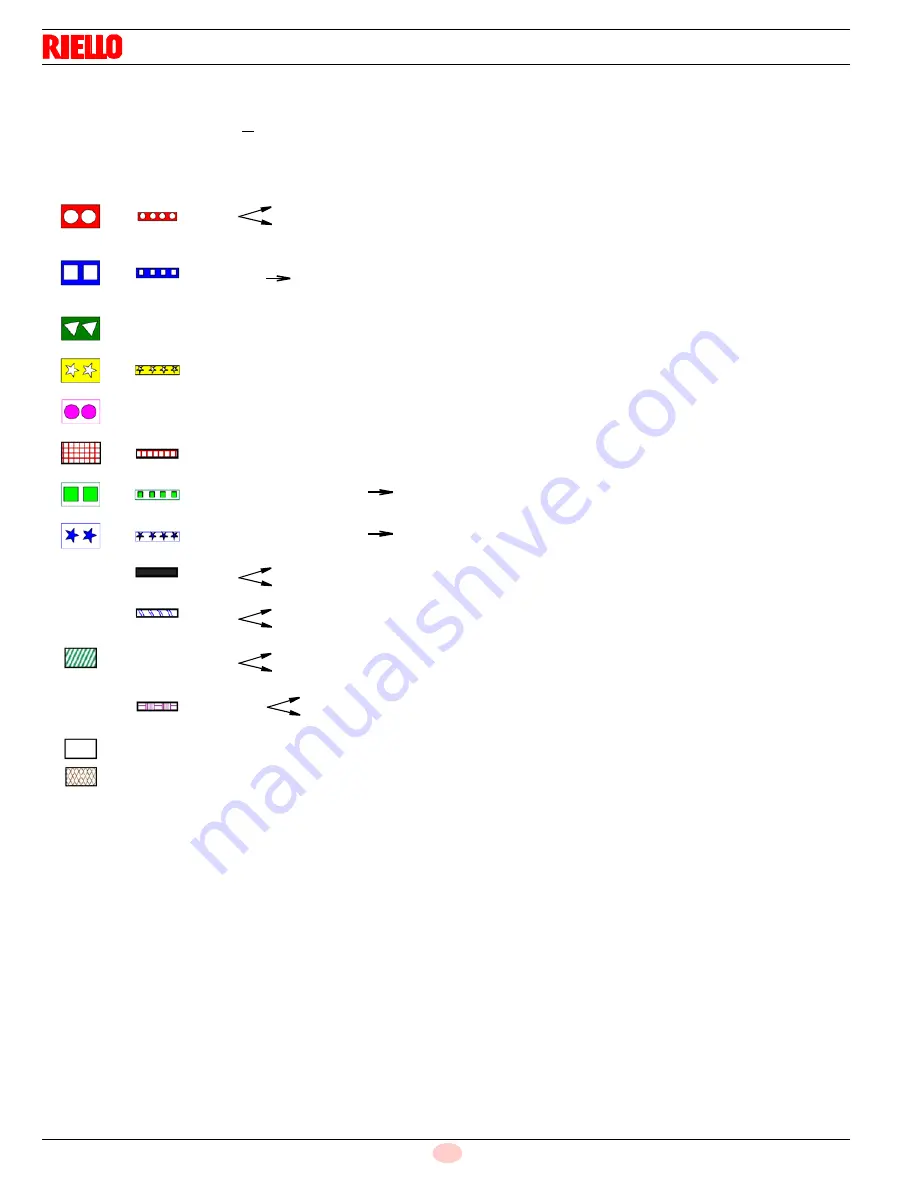

Legend to the sequence diagrams:

Depending on the parameter, valve proving takes place:

between phase 62 and phase 70 or/and

between phase 30 and phase 32.

Assignment of times:

t0

Postpurge lockout position

t01

Max. time safety phase

t10

Min. time home run

t21

Min. time start release

t22

Fan runup time t30 Prepurge time part 1

t34

Prepurge time part 3

t36

Min. ON time oil pump

t38

Preignition time gas / oil

t42

Preignition time OFF

t44

Interval 1 gas / oil

t62

Max. time low-fire

t70

Afterburn time

t74

Postpurge time 1 gas / oil (tn1)

t78

Postpurge time 3 gas / oil (tn3)

t80

Valve proving evacuate time

t81

Leakage test time atmospheric pressure

t82

Leakage test filling test

t83

Leakage test time gas pressure

tmn1

Min. time extraneous light test (5 s.) after skip over of pre-

purge

tmx1

Max. damper running time

tmx2

Max. time startup release

tmx3

Max. time circulation heavy oil

tn

Postpurge time

TSA1 Safety time 1

TSA2 Safety time 2

tv

Prepurge time gas / oil

Signal ON Signal OFF Next phase

Parameter direct start

Checking with controller on

Deviation

10

No Rep. decrement

10

70

Without VP70 with VP80

62

Stop, up to Ph – max. time

01

Stop, up to Ph – max. time

10

Input: don´t care

Output: OFF

Output: ON

00, Rep = 0

12, Rep > 0

01

0-3 s.

00, Rep = 0

12, Rep > 0

01

0-30 s.

00, Rep = 0

12, Rep > 0

01

0-3 s.

00, Rep = 0

12, Rep > 0

01

79

10

Param.