20141167

12

GB

Technical description of the burner

4.12

Electrical control box

The control box is a control and supervision system for forced

draught burners, for intermittent operation (at least one controlled

shutdown every 24 hours).

Important notes

All interventions (assembly and installation operations,

assistance, etc.) must be carried out by qualified personnel.

Before modifying the wiring in the control box connection

area, fully disconnect the system from the power supply

(omnipolar separation).

Protection against electrocution from the control box and all

connected electric components is obtained with the correct

assembly.

Before any intervention (assembly and installation

operations, assistance, etc.), ensure the wiring is in order

and that the parameters are correctly set, then make the

safety checks.

Falls and collisions can negatively affect the safety

functions.

In this case, the control box must not be operated, even if it

displays no evident damage.

For safety and reliability, comply with the following

instructions:

–

Avoid conditions that can favour the development of

condensate and humidity. Otherwise, before switching on

again, make sure the control box is perfectly dry.

–

Static charges must be avoided since they can damage the

control box’s electronic components when touched.

Installation notes

•

Check the electrical wiring inside the boiler complies with the

national and local safety regulations.

•

Install switches, fuses, earth connection etc. in compliance

with local regulations.

•

Do not confuse the powered conductors with the neutral

ones.

•

Ensure that spliced wires cannot get into contact with

neighbouring terminals. Use adequate ferrules.

•

Arrange the H.V. ignition cables separately, as far as

possible from the control box and the other cables.

•

When wiring the unit, make sure the 230V AC mains voltage

cables are run strictly separate from extra low-voltage cables,

to avoid the risk of electrocution.

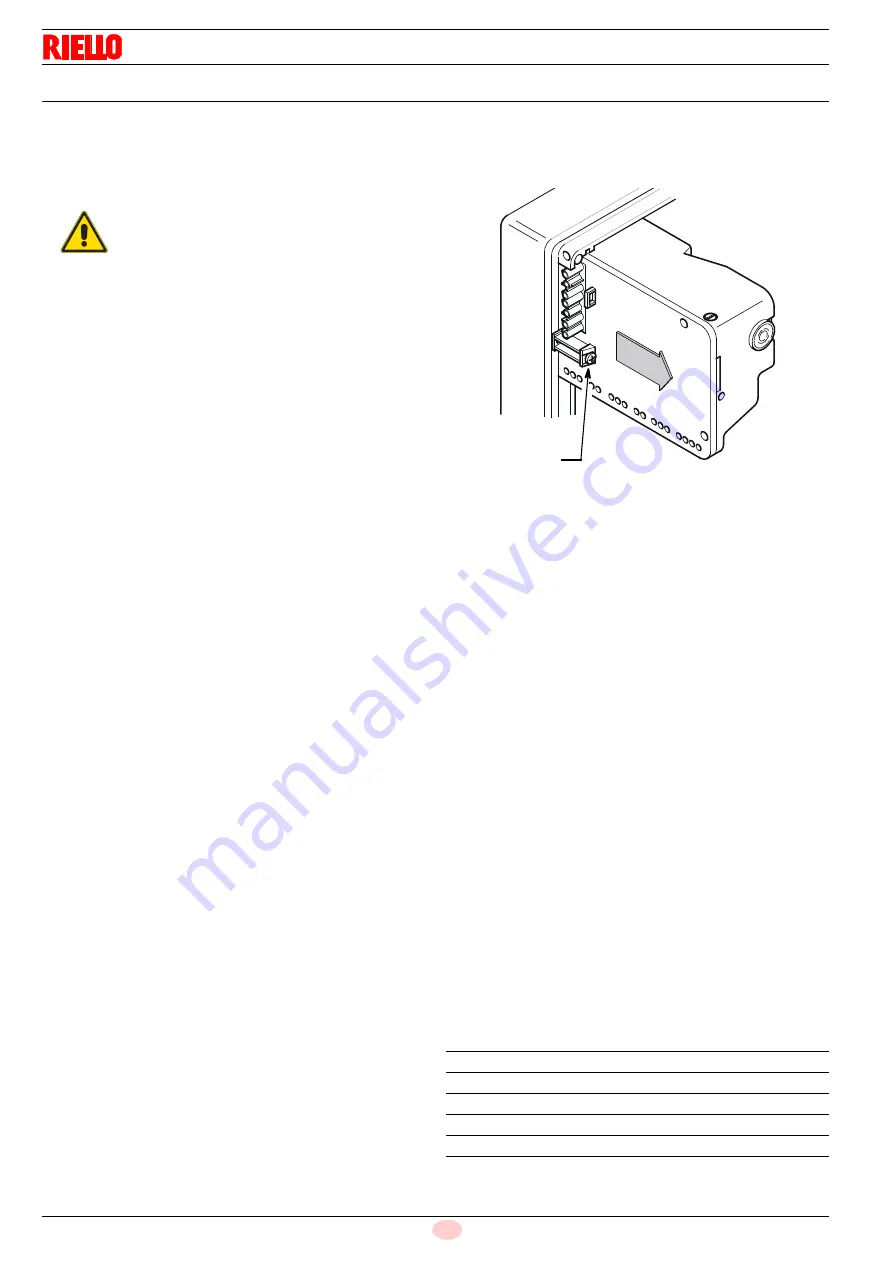

To remove the control box from the burner it is necessary to

(Fig. 5):

disconnect all the connectors connected to it, all the plugs,

the high voltage cables and the earth wire (

TB

);

unscrew the screw (

A

) and pull the control box in the

direction of the arrow.

To install the control box it is necessary to:

tighten the screw (

A

) with a tightening torque of 1 - 1.2 Nm;

reconnect all previously disconnected connectors, making

sure to connect the 7 pin power plug as the final step.

NOTE:

The burners have been approved for intermittent operation.

This means that they must stop once every 24 hours to

permit the electrical control box to check its efficiency at

start up. The boiler limit thermostat (TL) normally ensures

the stopping of the burner. If this is not the case, it is

necessary to apply a timer switch in series to the limit

thermostat (TL) that turns off the burner at least once every

24 hours.

Electrical wiring of ionisation probe

It is important for signal transmission to be almost totally free

of any disturbances or loss:

•

Always separate the probe cables from the other cables:

– the line capacity reduces the magnitude of the flame

signal;

– use a separate cable.

•

The cable length must not exceed 1 m.

•

Respect the polarity

•

Insulation resistance

– must be at least 50 M

between the ionisation probe and

the earth;

– a dirty detector reduces the insulation resistance, fostering

leakage currents.

•

The ionisation probe is not protected against the risk of

electrocution. When connected to the electricity supply, the

ionisation probe must be protected against any accidental

contact.

•

Position the ionisation probe so that the ignition spark cannot

form an arc on the probe (risk of electric overcharge).

Technical data

Tab. G

ATTENTION

To avoid accidents, material or environmental

damage, observe the following instructions!

The control box is a safety device! Avoid opening

or modifying it, or forcing its operation. The

Manufacturer cannot assume any responsibility

for damage resulting from unauthorised work!

Mains voltage

AC 210... 230 V -15 % / +10 %

Mains frequency

50/60 Hz ±6%

Built-in fuse

T4A 250V

Energy consumption

40 VA

Protection level

IP00

Fig. 5

E9275

A