37

20151674

GB

Operation, indications, diagnostic

8.3

Resetting of burner control

When a lockout occurs, the burner control can be immediately re-

leased by pressing the “RESET” button.

NOTE:

For the meaning of the diagnostic codes and errors, see the

chapter “Error code list with operation via the control box control

panel” on page 36.

8.3.1

Diagnostics of the cause of the fault

After the lockout, the faults indicator lamp stays on fixed. Under

these conditions, it is possible to activate the visual diagnostic of

the cause of the fault based on the table of colour codes by keep-

ing the reset button pressed for more than 3 seconds (info but-

ton).

Press the reset button again (info button) for at least 3 seconds

to activate the diagnostics interface.

If the diagnostic interface is started accidentally, a condition sig-

nalled by the blinking red indicator light, it can be deactivated by

pressing the reset button again (info button) for > 3 seconds.

The switching moment is indicated by a pulse of yellow light.

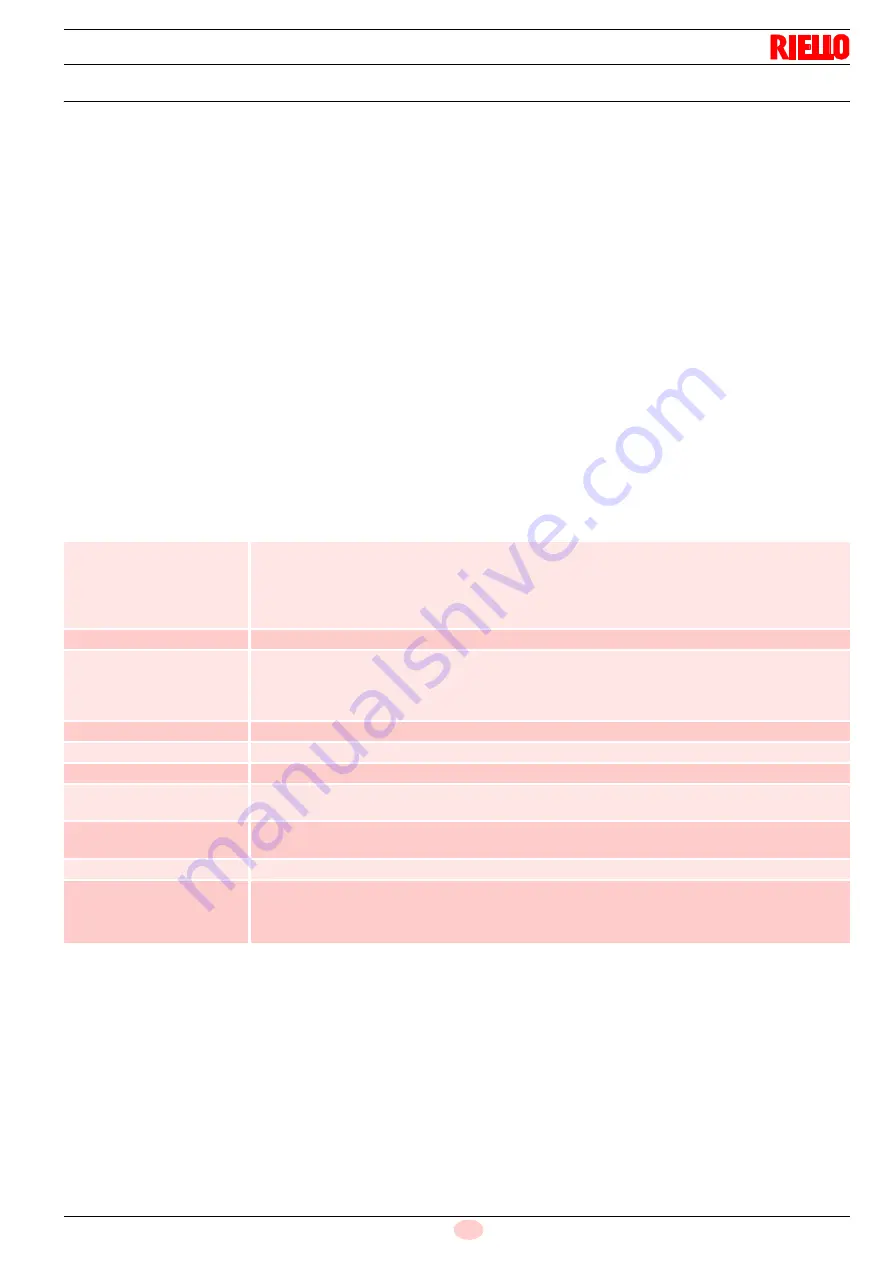

Tab. Y

During the diagnosis of the cause of the fault, the outputs of the

controls are disabled

–

The burner stays off

–

Indication of external fault (alarm) on the clamp X2-03, foot 3

on fixed

At the outlet of the diagnostic of the cause of the fault the burner

is switched on again by resetting the burner control.

Press the reset button (info button) for about 1 second (< 3 sec-

onds).

Error code table

Red blink code

fault indicator light

Possible cause

2 blinks

No flame at the end of the safety time

–

Fuel valves dirty or defective

–

Flame detector dirty or defective

–

Burner not adjusted correctly, no fuel

–

Ignition device defective

4 blinks

–

Extraneous light at burner start-up

7 blinks

Too many flame losses during operation (limitation of repetitions)

–

Fuel valves dirty or defective

–

Flame detector dirty or defective

–

Burner adjustment incorrect

8 blinks

Free

9 blinks

Free

10 blinks

Wiring error or internal error, outlet contacts, other faults

12 blinks

Valve test

–

Fuel valve 1 leak

13 blinks

Valve test

–

Fuel valve 2 leak

14 blinks

POC error valve closure control

15 blinks

Error code

15 (e.g. according to the type of program module)

error code 20: Min gas pressure switch fault

error code 22: Safety loop error

Summary of Contents for RX 150 S/PV

Page 2: ...Translation of the original instructions...

Page 48: ...20151674 46 GB Appendix Electrical panel layout 0 1 0 0 1 0 RX 150 S PV...

Page 49: ...47 20151674 GB Appendix Electrical panel layout...

Page 50: ...20151674 48 GB Appendix Electrical panel layout...

Page 51: ...49 20151674 GB Appendix Electrical panel layout 0 0 0 1 1...

Page 54: ......

Page 55: ......