20151717

24

GB

Installation

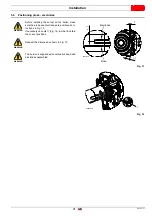

5.8.2

Gas train

This has been type-approved together with the burner, in accord-

ance with regulation EN 676, and is supplied as standard.

Gas input pipe

2

Manual valve

3

Valve including:

- filter (replaceable) (F)

- working valves (V1 - V2)

- pressure adjuster (R)

4

Pilot valve including:

- manual valve (VM)

- pressure adjuster (PR)

- safety valves (VP1 - VP2)

P1 Pressure upline of the filter

P2 Downstream pressure of valve

P3 Downstream pressure of pilot

Tab. N

DANGER

Disconnect the electrical power using the main

switch.

Check that there are no gas leaks.

Pay attention when handling the train: danger of

crushing of limbs.

Make sure that the gas train is properly installed

by checking for any fuel leaks.

The operator must use the required equipment

during installation.

Fig. 18

V1

V2

R

F

1

2

3

P1

P2

VP1

1

PR

VP2

P3

4

VM

20127964

GAS TRAINS

MAXIMUM INLET

PRESSURE

BURNER

MODEL

IN

OUT

mbar

MODEL

USE

VR 425 VA 1009

1”

1”

100

RX 360 S/PV

G20/G25

VR 420 VA 1004

1”

1”

100

RX 360 S/PV

LPG

Summary of Contents for RX 360 S/PV

Page 2: ...Translation of the original instructions...

Page 68: ...20151717 63 Appendix 0 0 0 1 0 2 0 0 0 0 0 0 0 0 0 0 1 0...

Page 69: ...64 20151717 Appendix...

Page 70: ...20151717 65 Appendix 0 1 1 1 1 1 1...

Page 71: ...66 20151717 Appendix 0 0 0 1 1 2 3 435678...

Page 75: ......