29

20151717

GB

Calibration and operation

6.3

Visualisation and programming modes

The operator panel, and especially the display visualisation, has

4 working modes:

Normal Mode

Info Mode (

InFo

)

Service Mode (

Ser

)

Parameter Mode (

PArA

)

The information for accessing and operating at the various levels

is given below.

Visualises the operation conditions and allows you to modify the

operation point of the burner manually.

It does not require any use of the keys of the operator panel.

It allows access to the other visualisation and programming

modes.

Some examples in the standard conditions are given below.

6.3.1

Operation

Normal display

Normal display is the standard display during normal operation,

which is the higher menu level. From normal display it is possible

to pass to the Info, Service or Parameters level.

Display in standby mode.

The unit is in standby mode.

Note:

OFF flashes when the manual switching off function or the

manual control

are active, and when the regulator is off.

Display during starting/stopping.

Displaying the program phases

.

The unit is in phase 30. The regulator requires heat.

The bar is displayed under the symbols

and

.

The individual phases of the program and the components con-

trolled are displayed according to the sequence of the program.

Normal

Mode

WARNING

Eventual modifications to the parameters and the

settings should be set and saved only in the unit's

internal memory.

To save the modified settings in the PME7... pro-

gram module, the backup should be activated

manually. Otherwise there is the risk of losing the

safety functions.

WARNING

At the first start-up or after replacing the program

module, the sequence of the functions and the pa-

rameter settings should be checked when the re-

store process ha finished. Otherwise there is the

risk of losing the safety functions.

WARNING

If the parameters need to be changed, a backup

copy must be made! Otherwise there is the risk of

losing the safety functions.

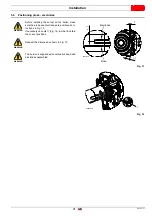

D9002

P

h

V

min s

%

Fig. 26

S9028

Fig. 27

o

o

o

o

o

o

o

o

Summary of Contents for RX 360 S/PV

Page 2: ...Translation of the original instructions...

Page 68: ...20151717 63 Appendix 0 0 0 1 0 2 0 0 0 0 0 0 0 0 0 0 1 0...

Page 69: ...64 20151717 Appendix...

Page 70: ...20151717 65 Appendix 0 1 1 1 1 1 1...

Page 71: ...66 20151717 Appendix 0 0 0 1 1 2 3 435678...

Page 75: ......