19

20029918

GB

Operation

6.7

Combustion head

The combustion head comprises a highly thermal resistant cylin-

der whose surface features numerous holes, encased in a metal

"mesh" (Fig. 16).

The air-gas mixture is pushed inside the cylinder and out of the

head through the holes in the perimeter.

Combustion starts when the air-gas mixture is ignited by a spark

generated by the electrode.

The metal "mesh" is the combustion head's most essential ele-

ment since it improves burner performance considerably.

The flame developed on the surface of the head is perfectly re-

tained and adheres to the mesh when operating at the maximum

setting. This allows modulating ratios as high as 6:1, avoiding the

danger of flashback when modulating is at its minimum.

The flame features an extremely compact geometry, meaning

that there is no risk of contact between the flame and parts of the

generator, consequently eliminating the possible problem of poor

combustion.

The flame's structure means that smaller combustion chambers

can be developed, designed to exploit this particular feature.

6.8

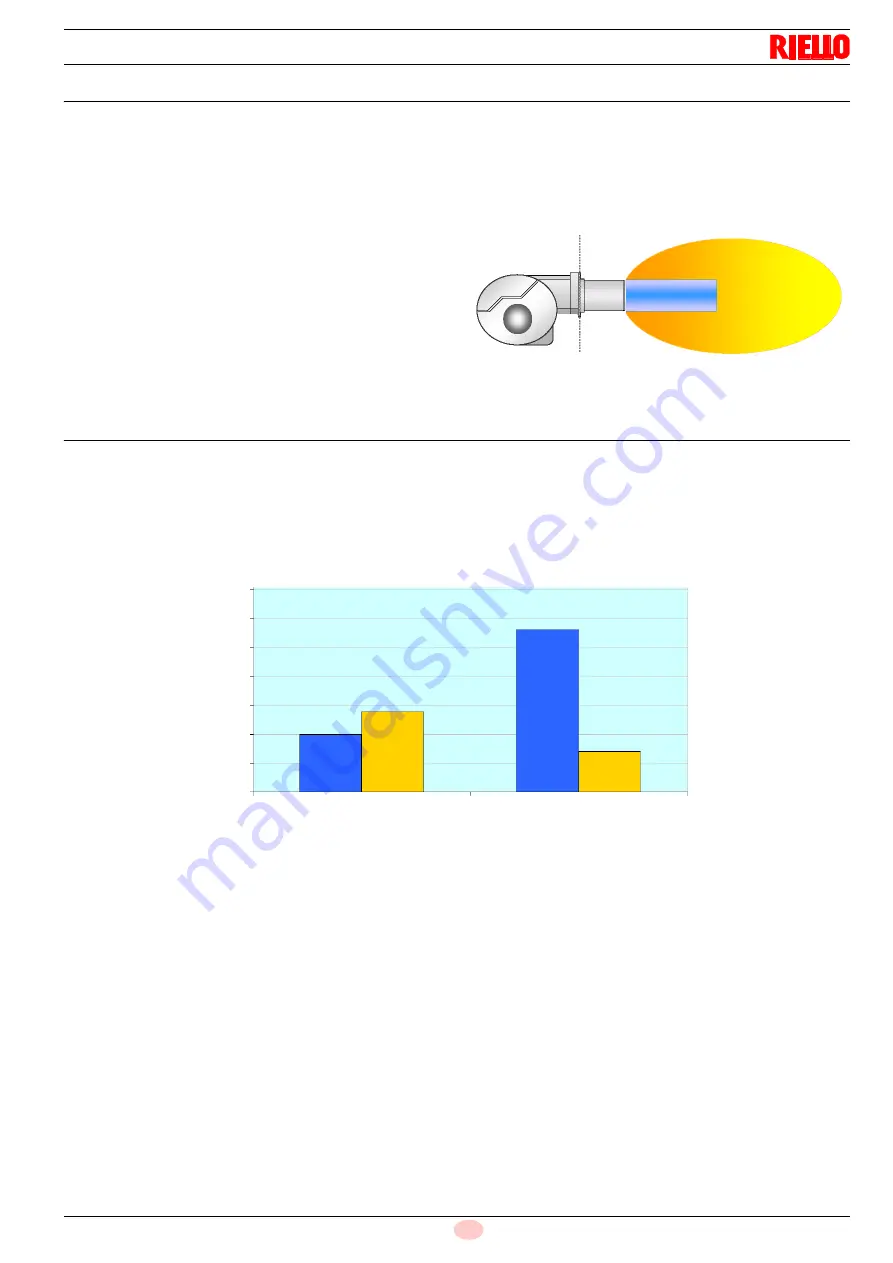

Emissions

The emission values of the burners are much lower than the limits

laid down by the strictest standards.

The flame's distribution and its spread over a large surface

means that the burner manages to limit the formation of ther-

mal NOx, the main causes of pollutant emission.

Fig. 16

D9714

mg/kWh

NOx

CO

NOx

CO

CLASS 3 LIMIT = 80 mg/kWh

70

60

50

40

30

20

10

0

Fig. 17

Maximum

modulation 35 kW

Minimum

modulation 7 kW