13

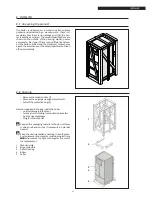

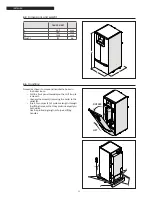

GENERAL

The storage cylinder pump conforms to the 2015 ERP Di-

rective. The pump is suitable for use in central heating/

domestic hot water applications and can function with

4 different head curves.

The pump runs at maximum speed and produces the

head/flow rate determined by the selected curve.

Each curve is characterised by a maximum head ex-

pressed in metres.

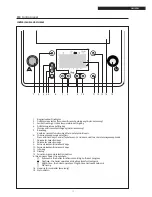

User interface

The user interface features one button (1), one red/

green LED (2) and four yellow LEDs.

LED (2)

BUTTON (1)

Via this interface, users can access:

− Functioning (performance display) mode. Pump

performance is displayed during functioning as

a % of current draw with respect to rated load.

Alarm conditions can be seen from the colour of

LED (2).

− Setting mode. Setting mode is accessed by

pressing the button (1), and is used to select the

pump curve.

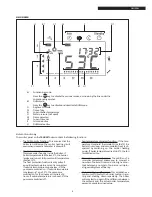

ADJUSTING THE PUMP

Display

Meaning

% power

LED 1 green and LED 2

yellow, both lit

Low load

0-25

LED 1 green and LEDs 2,

3 yellow, all lit

Low-medium

load

25-50

LED 1 green, LEDs 2, 3,

4 yellow, all lit

Medium-high

load

50-75

LED 1 green, LEDs 2, 3,

4, 5 yellow, all lit

High load

75-100

PUMP LOAD CURVE

100 %

75 %

50 %

25 %

Functioning mode

A) Performance display

When the pump is functioning, LED 1 is green. The four

yellow LEDs indicate the instantaneous power draw as

shown in the table above. In functioning mode, all ac-

tive LEDs are lit (not flashing) to differentiate this con-

dition from setting mode. If the pump is stopped by the

external control signal, LED 1 flashes green.

B) Alarm display

If the pump detects one or more alarm conditions, LED 1

changes from green to red. When an alarm is active, the

LEDs indicate the type of alarm as shown in the follow-

ing table. If more than one alarm is active at the same

time, the LEDs only show the alarm condition with the

highest priority. Alarm priority follows the order of the

table.

When no alarm is active, the user interface automati-

cally displays pump performance.