28

INSTALLER

WATER IN CENTRAL HEATING SYSTEMS:

INSTRUCTIONS FOR THE DESIGN, INSTALLATION AND MANAGEMENT OF CENTRAL HEATING SYSTEMS .

1

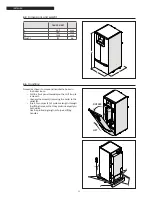

CHEMICAL AND PHYSICAL CHARACTERISTICS OF WATER

The chemical and physical characteristics of water used in central heating systems must conform to the

requirements of EN 14868 standard and to the following tables:

ALUMINIUM BOILERS

with furnace power < 150 kW

Water used for

first filling

Water with sy-

stem operating

(*)

ph

6-8

7-8

Hardness

°fH

< 10°

< 10°

Electrical

conductivity

μs/

cm

< 200

Chlorides

mg/l

< 25

Sulphides

mg/l

< 25

Nitrides

mg/l

< 25

Iron

mg/l

< 0,5

ALUMINIUM BOILERS

with furnace power > 150 kW

Water used for

first filling

Water with sy-

stem operating

(*)

ph

6-8

7-8

Hardness

°fH

< 5°

< 5°

Electrical

conductivity

μs/

cm

< 150

Chlorides

mg/l

< 15

Sulphides

mg/l

< 15

Nitrides

mg/l

< 15

Iron

mg/l

<0,5

(*)

values for water in system after 8 weeks of functioning

General note on water used to top up systems:

− If softened water is used to top up a system, 8 weeks of functioning after topping up, verify that the water in

the system respects the above limits, in particular for electrical conductivity.

− This check is not necessary if demineralised water is used to top up the system.

2 .7

Water in heating circuits

INTRODUCTION

Water used in central heating systems MUST be suitably

treated to ensure the correct functioning of those sy-

stems and to guarantee an extended working life for

boilers and all other system components.

This applies not only to existing systems but to newly

installed systems too.

Sludge, limescale and other contaminants in water can

cause irreversible damage to boilers even in relatively

short times, and despite the use of top quality materials

in their manufacture.

Contact

R

’s Technical Assistance Service for further

information on water additives and their use.

9

Always conform to the standards and legislation

applicable in the country of installation.