34

INSTALLER

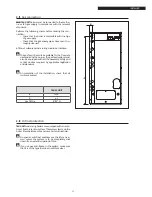

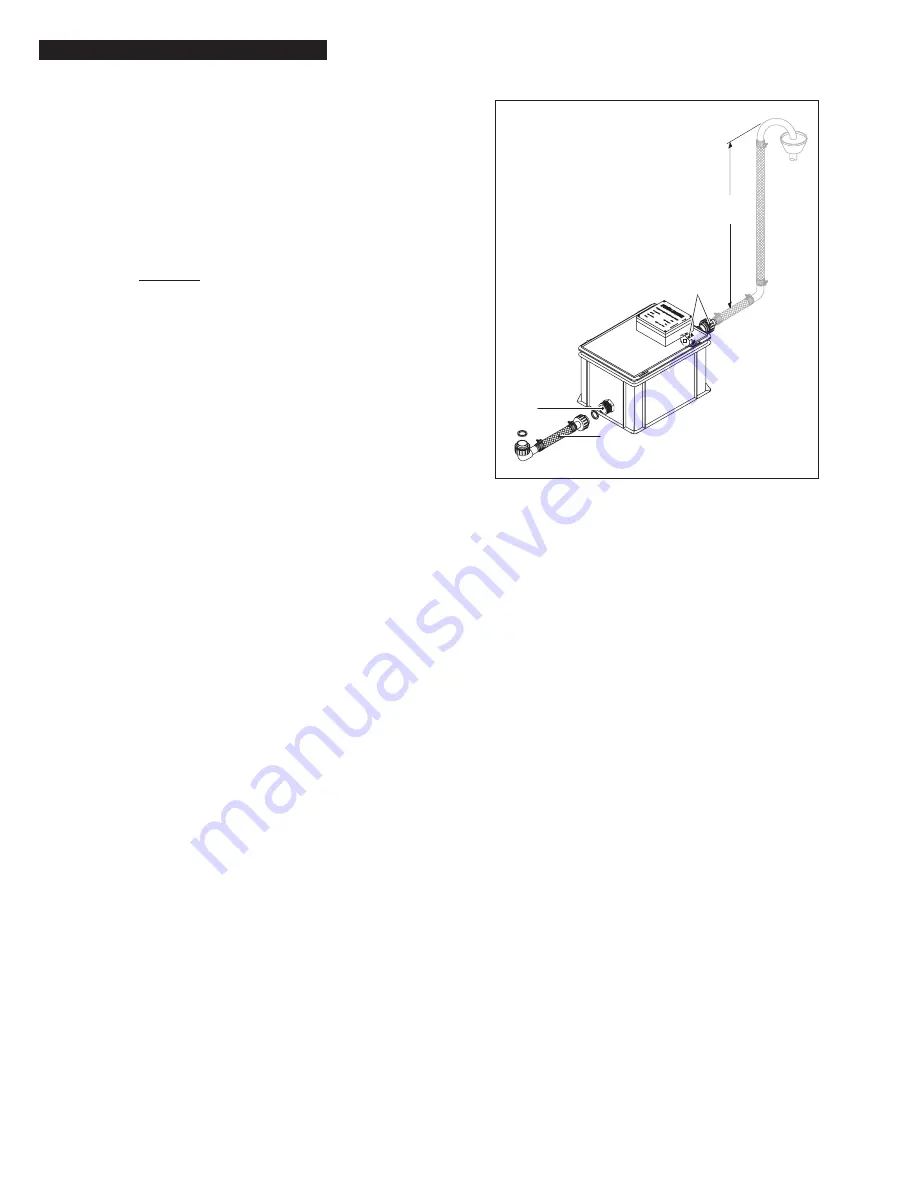

The inlet fitting (A) of the HN2 neutralisation unit (the

lower fitting) must be connected to the boiler conden-

sate drain fitting using the flexible hose (C) supplied.

This condensate drain hose is specially made to prevent

combustion fumes escaping into the atmosphere.

The outlet fitting (B) of the neutralisation unit (the top

fitting) must be connected to the boiler room’s waste

water drain pit using another section of flexible hose

(not supplied).

IMPORTANT

The boiler room’s condensate drain pit must be located

no more than 1.5 metres above the neutralisation unit.

9

All connecting hoses must be kept as straight and

as short as possible. Any curves or sharp bends can

lead to the hoses becoming clogged and can there-

fore prevent proper condensate discharge.

Hoses should also be fixed to the floor and suitably

protected whenever possible.

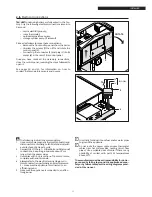

MAINTENANCE

The neutralisation unit should be serviced at regular in-

tervals (at least once a year) or as needs require. The

frequency of servicing depends on the characteristics of

the system. When servicing the unit, always check the

level of the granulate. The minimum granulate level is 15

cm below the top of the granulate box. The initial char-

ge of neutralisation product should be enough to last at

least one season of heating operation with maximum

condensate formation.

The easiest way to check the correct functioning of the

neutralisation unit is to use litmus papers for pH te-

sting. These are readily available from chemists’ shops

and chemical suppliers. Treated condensate leaving the

unit must have a pH between 6.5 and 9. If limescale

forms on the surface of the neutralisation unit, replace

the entire granulate charge.

B

(1”)

1,5 m

max

A

(1”)

C

NH2