6

GENERAL

1 .3

Product description

This

TAU UNIT

condensing boiler is designed to produce

hot water for central heating systems. If used in conjun-

ction with a remote storage cylinder, it can also produce

domestic hot water. The innovative boiler body uses the

condensation of steam from the combustion gases to

recover up to 15% extra energy, with obvious benefits

in terms of running costs. The boiler body is made from

highly corrosion resistant stainless steel to guarantee an

extended working life and excellent reliability. The boi-

ler body conforms to the strictest Italian and European

standards governing the migration of heavy metals to

condensate. A premixed micro-flame burner guarante-

es extremely low emissions.

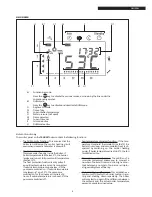

The control system applies compensated control logic to

maximise energy recovery in all seasons. The combu-

stion gases are cooled to a temperature near that of the

central heating return before they leave the boiler body.

This makes it possible to use plastic flue pipes instead

of metal ones, with significant savings in overall instal-

lation costs.

Special accessories are available to increase the number

of central heating circuits served, to cascade a number

of

TAU UNIT

boilers and to connect single or double re-

turn lines to suit the needs of the installation, impro-

ving heat stratification in the water inside the body and

optimising performance.

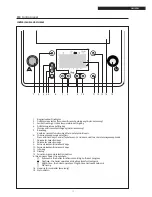

1 .4

Safety devices

This

TAU UNIT

condensing boiler is equipped with the following safety devices

An automatic

safety thermostat

that trips at 100° and

shuts down the burner.

An

electronic safety system

that monitors flow rate

through the central heating system using two sensors,

one on the flow pipe and the other on the return pipe.

This safety system forces the boiler to perform a safety

shutdown if flow rate is insufficient or not detected.

Flue gas safety thermostat

.

A flue gas thermostat in the bottom of the heat exchan-

ger that triggers an error condition if flue gas tempera-

ture exceeds 75°C. A flue gas temperature sensor in the

bottom of the heat exchanger that triggers a transient

error if flue gas temperature exceeds 85°C and a perma-

nent error if it exceeds 90°C.

A fan safety system

that uses a Hall effect speed sensor

to continuously monitor fan speed.

9

The activation of a safety device indicates a poten-

tially dangerous malfunction in the modulation

system. Contact

R

’s Technical Assistance Service

immediately.

You may attempt to restart the boiler after a short

delay (see “Preparing for initial start-up”).

0

Never start the boiler up even for a short period if

the safety devices are not functioning correctly or

have been tampered with.

9

Safety devices must only be replaced by

R

’s Tech-

nical Assistance Service using original spare parts.

Refer to the spare parts catalogue supplied with the

boiler.

Always check that the boiler is functioning correctly after

any repairs.