Introduction

The detector «Steklo-3» (hereinafter, the Detector):

- is intended for detecting destruction of all known kinds of construction

glass: common, quenched, patterned, armored, multilayer and laminated

with polymer film, glass units, as well as hollow glass blocks installed in

structural units (openings) and/or interior elements of closed spaces;

- generates alarm messages by control relay contacts opening;

- ensures case tamper protection;

- may be installed on the wall, ceiling or on a pier between the

monitored glass and curtains.

Features of the Detector

The Detector:

- ensures remote monitoring of controlled glazed structures of any

shape;

- detects destruction of all known kinds of construction glass of

different dimensions and shapes;

- provides multilevel microprocessor signal processing and functional

self-test;

- offer to user an opportunity to choose algorithm of the Detector

operation in dependence on situation on the secured object or on

chosen security tactics;

- displays the Detector status information and noise interference by

means of LED indication;

- possibility of LED indication disabling;

- operates in temperature range from minus 20 up to + 45

0

С, supply

voltage range 9 … 17 V.

Scope of Delivery

Each Detector unit package contains the items listed in Table 1.

Table 1

Name

QNT

Glass Break Detector «Steklo-3»

Testing steel ball

Screw 3-3х30

Glass Break Detector «Steklo-3». Installation Guide

1 pc.

*

2 pcs.

1 copy

* – Supplied optionally

Field of Application

The Detector can be applied in offices, shops, museums, exhibition

halls, banks, accommodation rooms, etc.

Choosing the Detector Location

Before installing the Detector, get acquainted with the following

requirements:

- when choosing the place of installation, the Detector detection zone

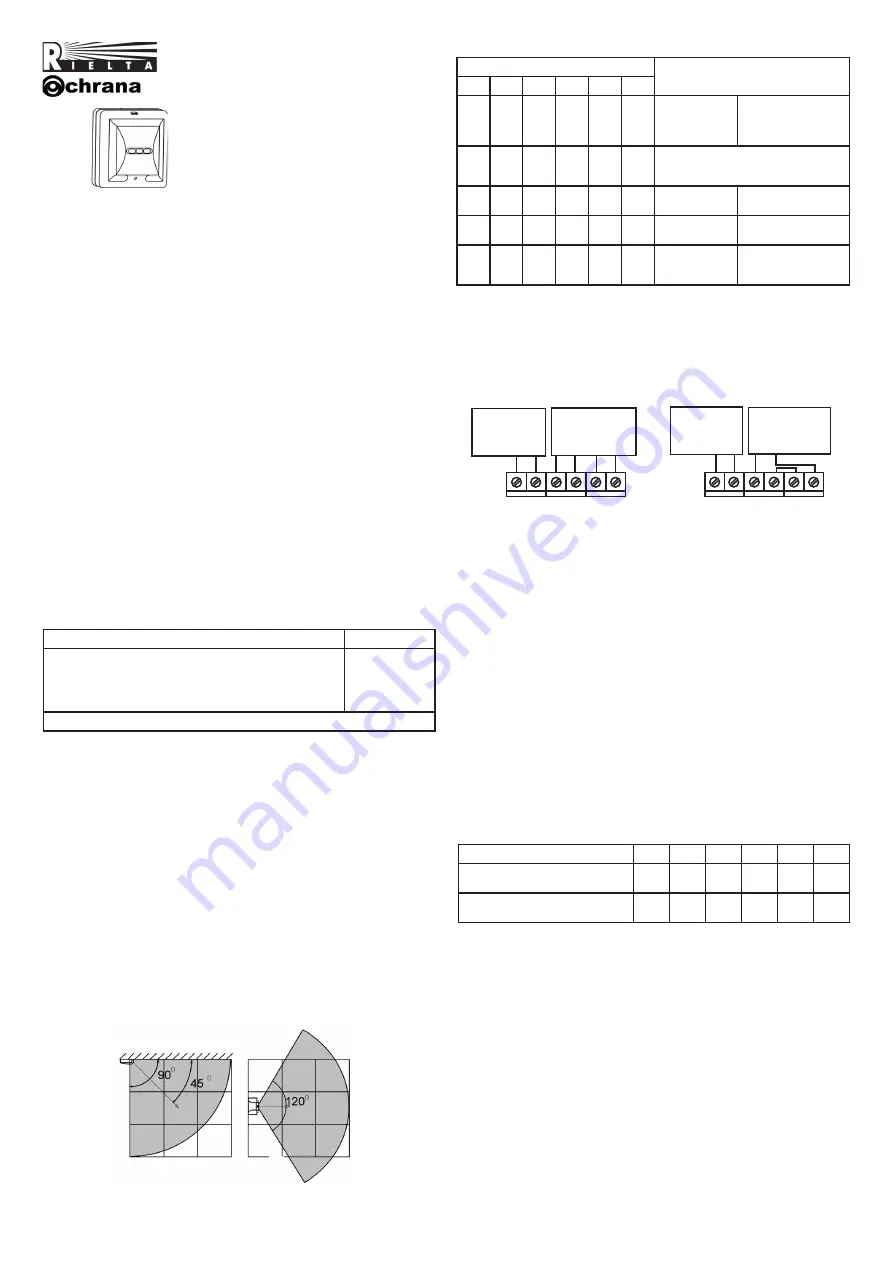

location must be taken into account (Figure 1);

- it is recommended to install the Detector at least 2 m height (see

examples of installation in Figures 4 – 8);

- during joint operation with an active ultrasonic Detector, distance

between Detectors must be not less than 1 m;

- the entire surface of the monitored glass should be available within

the direct visibility of the Detector;

- distance (L) between the Detector and the farthest point of the

monitored glass should not exceed 6 m. If square of a secured glass

exceeds 1 m

2

, distance L can be increased up to 9 m;

- for protection of any type of glasses listed in Table 2, universal mode

of the Detector operation can be applied.

GLASS BREAK

DETECTOR

«STEKLO-3»

Adjustment

Set the «1», «2» and «5» DIP-switches to the ON position. Energize the

Detector. At this time the red LED indicator («Alarm» message indicator)

should light for 2 – 10 sec and go out, that indicates the Detector

changing to standby mode.

Estimate the interference situation in the room. Yellow LED indicator

lighting is an evidence of high-frequency interference in the room. Green

LED lighting means low-frequency interference presence. Eliminate the

cause of interference wherever it is possible.

Fulfill the Detector adjustment as follows:

- set DIP-switches «1» and «2» in OFF position, DIP-switch «6» – in

ON position, DIP-switches «3» and «4» – in OFF position;

- suspend a steel ball 21

– 22 mm in diameter on a 35 cm long thread

near the farthest part of the monitored glass (ordinary, ornamental,

armed, laminated), deflect it at an angle of 30 – 70° (see Table 3, 45°

for hollow glass blocks). Deliver a blow to the most distant place of

the secured glass. If red indicator is not lighting after test blows, the

Detector sensitivity should be increased by DIP-switches «1» and «2»

(See Table 2).

Table 3

Glass thickness, mm

<3

3...4

4...5

5...6

6...7

>7

Ball deflection angle for ordinary,

armed and ornamental glass,

0

30

35

40

45

50

55

Ball deflection angle for,

hardened and laminated glass,

0

45

50

55

60

65

70

– for monitoring a multilayer glass or a small area of glass, it is allowed

to use electronic glass break simulator during adjustment;

- check the correctness of the Detector adjustment with the Detector

cover installed;

– after completing the Detector adjustment, set DIP-switch «6» to

OFF position and choose the mode of operation by «3», «4» and «5»

DIP-switches (See Table 2) in accordance with type of secured glass

and security tactics accepted on the object.

Manufacturer’s Guarantees

The manufacturer guarantees conformity of the Detector to the

Technical Specifications requirements provided the transportation,

storage, installation and operation conditions are observed.

The guaranteed shelf life of the Detector is 63 months since the date

of manufacture.

The guaranteed useful life is 60 months since the day of putting into

operation within the guaranteed shelf life.

The Detectors that are found non-conforming to the Technical

Specifications requirements shall be repaired by manufacturer, provided

the installation and operation rules have been complied with.

Table 2

DIP-switch position

Detector Operating Mode

1

2

3

4

5

6

OFF

OFF

ON

ON

OFF

ON

OFF

ON

Sensitivity

(detection

range)

adjustment

minimum

+6 dB

+14 dB

+20 dB (maximum)

OFF

ON

Universal mode

Detection of glass destruction with

chip fallout

OFF

ON

Alarm memory

indication

– OFF

– ON

OFF

ON

LED indication

control

– OFF

– ON

OFF

ON

Standby mode

Adjustment

–

LED indicator

lighting green

The Detector Installation

Remove the cover and PCB of the Detector and fasten the Detector

with the help of screws. Choose the place of the Detector installation

and mark out it’s fastenings using the Detector base for the purpose.

The Detector Connection

Fulfill the Detector connection in accordance with Figures 2 or 3.

Installation Guide

Figure 1 – Glass Break (GB) channel Detection Pattern

Figure 2 –Separate Connection

of Alarm Loop and Tamper contact

Figire 3 – Joined connection of

Alarm Loop and Tamper contact

Power

Supply

CP

CP

+

12V

–

Power

Supply

Tamper

AL

Top View

Side View

6 m

6 m

+

–

AL1 AL2

+

–

AL

+

12V

–

Tamper

AL