FAN SPEED CONTROL ADR 80 - 230

ADR80230_5.04_eng

Project:

ADR Regulator

Revision Doc.:5,0

Date

: 29.05.2009

Page.

7

Setup

in ADR

Min

10 %

Max

85 %

Start

at 12.5 bar

End

at 20.0 Bar

SET

17 bar

Prop.-

band

2.5 bar

Note: Do not use a small proportional band otherwise you may expect hunting

Based on the setup above following control will be in function

Band in which you find a definite speed regulation

Start

Start of

prop.-band

Proportional-

band

SET Proportional-

band

End of

Prop.-Band

Full

Speed

Pressure bar

12.5

14.5

2.5

17.0

2.5

19.5

20.0

Temperature °C

>35.0

40°

40°- 46°

46°

46° - 52°

52°

53°

Voltage (output) in %

10

10

= 85%

100 %

6.4.0 To control two different Set points and how to define = DUO SET

The firmware in the EEPROM allows the usage of two different Set points. This with one sensor, with two of a kind or differ-

ent sensors (i.e. Temperature sensor and pressure transducer).

.

6.4.1 Window to set „DUO SET“

After your decision to use 2 sensors (Probes) follow option are open to be set.

Example: Pressure

Example input control parameter for DUO - SET

As before you can configure the control parameter for each Sensor in the subdirectory “REGULATION”

6.4.2 Sensors/Pressure transducer 1 or 2 Set points (DUO-SET)

Each sensor input can be defined separate according to the different Probes (Example)

Sensor 1 (P1)or (S1): Pressure via pressure transmitter, Sensor 2 (P2) or(S2): Temperature via temperature sensors NTC

Attention: Do not forget to place the correct jumper according to the sensor

6.

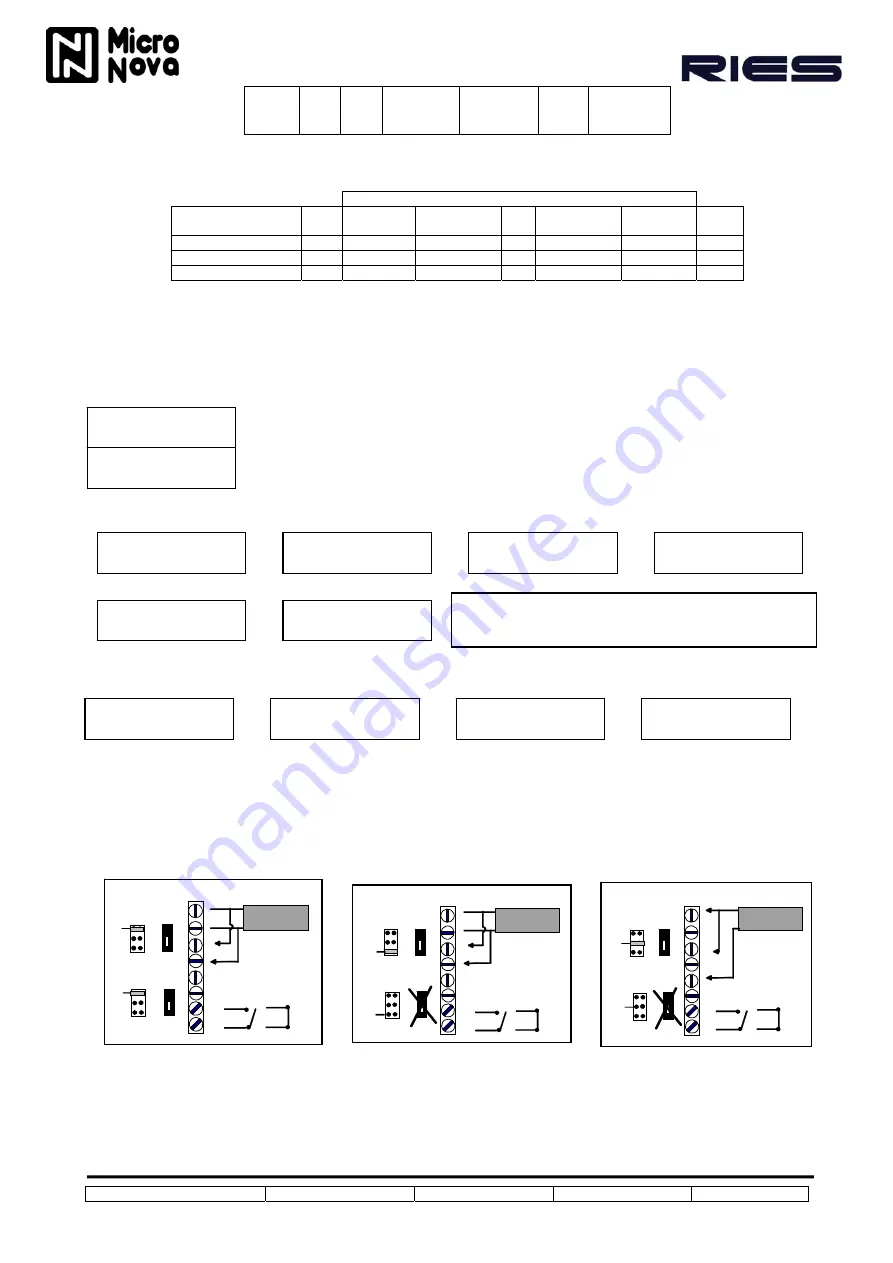

4.3 Wiring and placing jumpers for 2 set point but one sensor only

Attention: Bypass connection has to be made potential free (no voltage)

Depending to the sensor input Jumper have to be placed. Please consider for 1 sensor with 2 set points with open Bypass (SET1) control is fixed by set point S1.

With closed Bypass (SET2) control is taken over by set point 2

Î

PROBES FUNCtion

NORMAL

Ú

Î

P1

PROBE TYPE:

CURR 4 20 mA

Ú

Î

P1

MAX PRESSURE

IN BAR 30.0

Ú

Î

P1

REGULATION

PRESSURE

Ú

Î

P1

INPUT REG

IN BAR

Ú

Î

P1

FREON TYPE

FREON R22

Ú

Î

P1

WORKING IN

CHILLER

Ú

Î

P1

REGULATION

START 9.5 BAR

Ú

Î

P1

REGULATION

STOP 20.0 BAR

Ú

Î

P1 REGULATION

SET 17.0 BAR

Ú

Î

P1 REGULATION

BAND 2.0 BAR

Ú

V

JP1 (IN1)

V

JP2 (IN2)

IN1

IN

+12

GND

BY PASS

+

+

-

-

0 - 10 V

SET 1

SET 2

V

I

N

V

I

N

JP1 (IN1)

JP2 (IN2)

+12

GND

BY PASS

NTC - 10K

NTC

NTC

IN1

IN2

+

+

-

-

SET 1

SET 2

NO

V

I

N

V

I

N

mA

JP1 (IN1)

mA

JP2 (IN2)

+12

GND

BY PASS

0-20 / 4-20 mA

IN1

IN2

SET 1

SET 2

NO

V

I

N

V

I

N

+

-

-

Î

PROBES FUNCtion

INDEPENDANT

Ú

NORMAL

A „normal“control between both sensors

will take place. In function “Chiller” the

highest value of both sensor will control the

output of the ADR. In function “Heatpump”

the lowest value of both sensors controls

the output.

INDEPENDANT

The firmware offers for each sensor a

window for an individual programming of

each probe. No o matter if it is for tempera-

ture , pressure, external voltage or chiller

and heatpump

Same windows also available for Sensor (Probes)2

P1 = Sensor 1, P2 = Snesor 2