���

DCLF 40 D

DCLF 60 D

DCLF 80 D

DCLF 100 D

DCLF 130 D

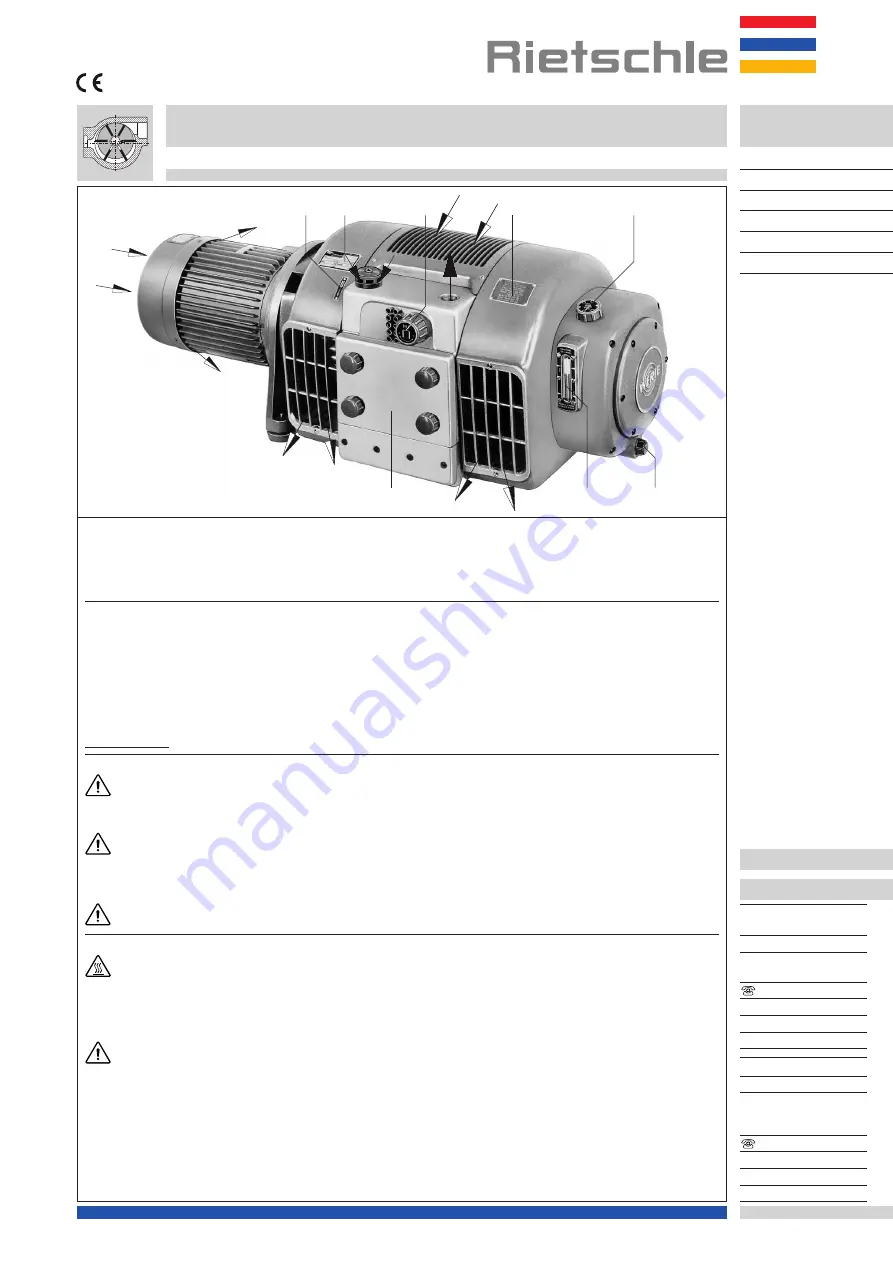

M

N

S

H

F

F

K

I

B

E

E

F

F

O

A

D

DCLF...D

Compressors

Operating Instructions

Pump ranges

These operating instructions concern the following oil lubricated rotary vane compressors: Models DCLF 40 D to

DCLF 130 D. All models have nominal capacities of 40, 60, 80, 100 and 130 m

3

/hr operating at 50 cycles. The pressure

limits (bar) are indicated on the data plate (N). The pumping curves showing capacity against pressure can be found

in data sheet D 350.

Description

All models are complete with a threaded connection on the exhaust and a suction knob on the inlet. All the air handled

is filtered by a built-in micro-fine filter. The oil separation of the compressed air which has the function of re-circulating

oil back into the circulation system is carried out by an oil separation system that needs very little maintenance. Metered

lubrication is achieved using a built in oil pump. High efficiency cooling fans are located between the compressor housing

and the motor resp. oil tank. The fan covers provide protection from accidentally touching the fans when the compressor

is in operation. The compressed air is cooled by an after cooler.

All the compressors are driven by a direct flanged three phase, standard TEFV motor via a pin and bush coupling.

Pressure can be adjusted to the required levels, however, they are limited to a maximum point.

Optional extras: As required, non return valve (ZRK), suction filter (ZAF),motor starter (ZMS) and star delta starter (ZSG).

Suitability

The units DCLF...D are suitable for the use in the industrial field i.e. the protection equipments

corresponds to EN DIN 294 table 4, for people aged 14 and above.

The DCLF...D units produce pressure up to the maximum limits, which are shown at the data plate (N). They may be

operated continuously.

Amounts of water vapour, water, other liquids, aggressive gases, or vapours may not be handled.

The ambient and suction temperatures must be between 5 and 40°C. For temperatures outside this range please

contact your supplier.

The standard versions may not be used in hazardous areas. Special versions with Ex-proof motors can be supplied.

For all applications where an unplanned shut down of the compressor could possibly cause harm to

persons or installations, then the corresponding safety backup system must be installed.

Handling and Setting up (pictures

���

,

���

and

���

)

Compressors that have reached operating temperature may have a surface temperature at position (Q) of

more than 70°C. WARNING! Do Not Touch.

For maintenance purposes we recommend a space of 0.3 m in front of filter housing (S), oil preseparator (T

1

) and oil

separator (T

2

). The cooling air entries (E) and the cooling air exits (F) must have a minimum distance of 20 cm from any

obstruction. The discharged cooling air must not be re-circulated.

The DCLF...D compressors can only be operated reliably if they are installed horizontally.

For installations that are higher than 1000 m above sea level there will be a loss in capacity. For further

advice please contact your supplier.

When installed on a solid base the compressors may be installed without fixing down. If the compressors are installed

on a base plate we would recommend fitting anti-vibration mounts. This range of compressors are almost vibration free

in operation.

BE 350

1.7.97

Werner Rietschle

GmbH + Co. KG

Postfach 1260

79642 SCHOPFHEIM

GERMANY

0 76 22 / 392-0

Fax 0 76 22 / 39 2300

E-Mail: info@rietschle.com

http://www.rietschle.com

Rietschle (UK) Ltd.

Bellingham Way

NEW HYTHE

KENT ME20 6XS

UNITED KINGDOM

0 16 22 / 71 6816

Fax 0 16 22 / 71 5115

E-Mail: info@rietschle.co.uk

http://www.rietschle.co.uk