���

���

G

b

e

m

s

f

m

D

s

s

Initial Operation (picture

���

)

1. Initially switch the compressor on and off for a few seconds to check the direction of rotation against the direction arrow (O).

Note: On this initial start the pressure pipework should not be connected. If the compressor runs backwards with the pipework

connected a pressure could build up within the housing which could result in damaged rotor blades.

2. Connect the pressure pipe at (B).

For pipework longer than 3 m we recommend using non-return valves (ZRK), to avoid reverse rotation when the units are switched

off.

3. The requested pressure ranges can be adjusted by turning the pressure regulating valve (D) according to the symbols on the top of the regulating

valve.

Potential risks for operating personnel

Noise Emission: The worst noise levels taking into consideration direction and intensity measured according to DIN 45635 part 3 (as per

3. GSGV), are shown in the table at the back. When working permanently in the vicinity of an operating compressor, we recommend wearing

ear protection to avoid any damage to hearing.

Maintenance and Servicing

When maintaining these units and having such situations where personnel could be hurt by moving parts or by live electrical parts,

the compressor must be isolated by totally disconnecting the electrical supply. It is imperative that the unit cannot be re-started

during the maintenance operation. Do not maintain a compressor that is at its normal operating temperature as there is a danger from

hot parts.

1. Lubrication

The DLT compresors have bearings that are greased for life. They need not be serviced.

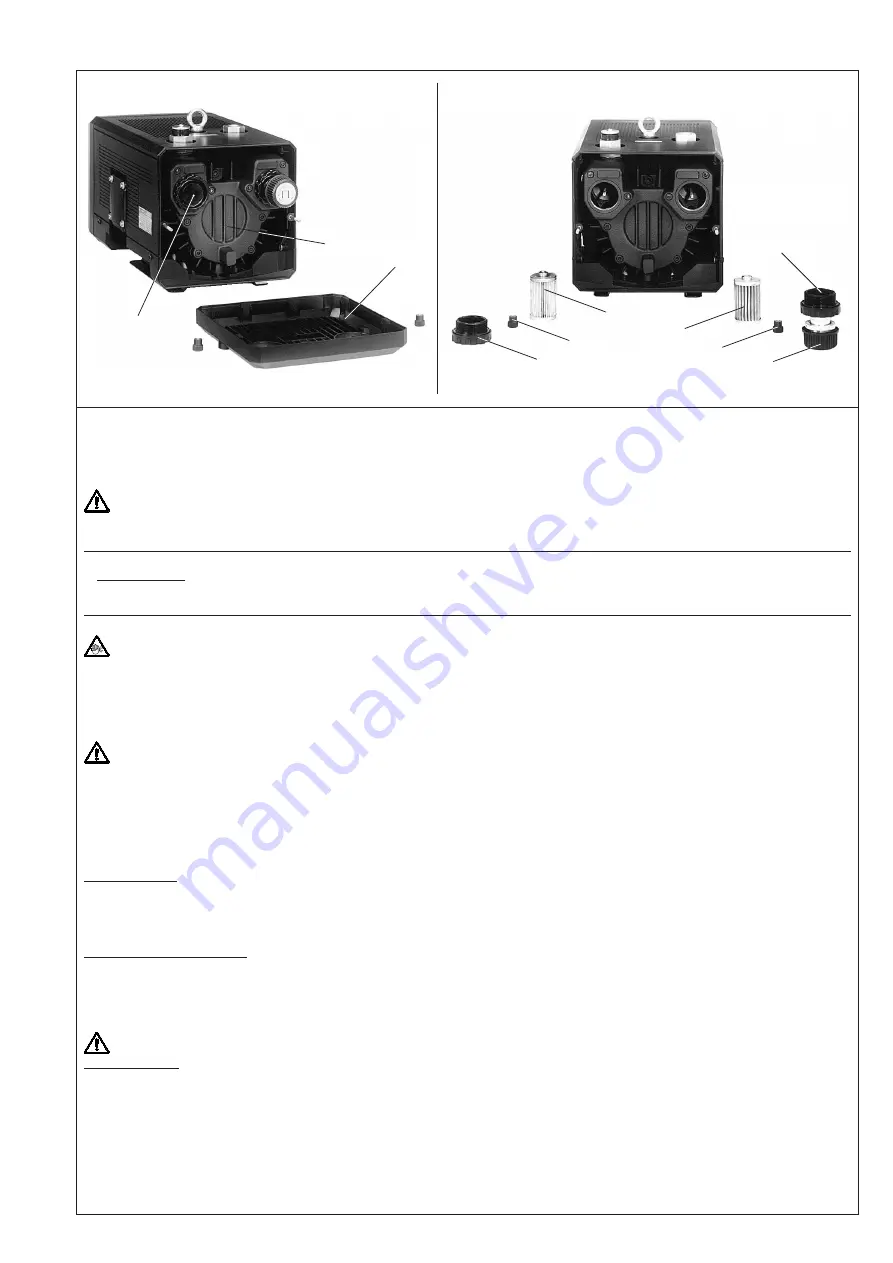

2. Air filtration (pictures

���

and

���

)

The capacity of the compressor can become reduced if the air inlet filters are not maintained correctly.

The filter cartridges (e) on the inlet and (f

➝

optional extras) for compressed air have to be cleaned depending on the amount of contamination.

This is achieved by blowing compressed air from the inside of the cartridge outwards. Even if the cartridges are cleaned their separating efficiency

deteriorates. We would therefore recommend exchanging the cartridges every six months.

Changing the filters:

Screw off exhaust grid (G). Remove screwed cover (s) and milled knob (m). Pull filter cartridges (e) and (f) off and clean or exchange. Re-assemble

in reverse order.

3. Blades (pictures

���

and

���

)

Checking blades: DLT 6 - 25 have 6 blades whilst the DLT 40 has 7 blades. The blades have a low but permanent wear factor.

DLT 6, DLT 10 and DLT 15: first check after 7,000 operating hours, thereafter every 1,000 operating hours.

DLT 25 and DLT 40: first check after 5,000 operating hours, thereafter every 1,000 operating hours.

Screw off exhaust grid (G). Screw off housing cover (b) from housing. Remove blades (d) for inspection. All blades must have a minimum

height (X):

Model

X (minimum height)

DLT 6

20 mm

DLT 10

20 mm

DLT 15

24 mm

DLT 25

24 mm

DLT 40

35 mm

Blades must be changed completely.

Changing blades: If the minimum height is reached, then the whole set of blades should be changed.

Before fitting new blades clean out the housing and the rotor slots with compressed air. Place the blades with the radius outwards (Y) so that the

bevel is in the direction of rotation (O

1

) and corresponds with the radius of the housing (Z).

Fix end cover (b) and exhaust grid (G). Before restarting the pump check free movement of the blades by turning the motor cooling fan before

refitting the cooling grid (G

1

).