/ PM6

e

d

s

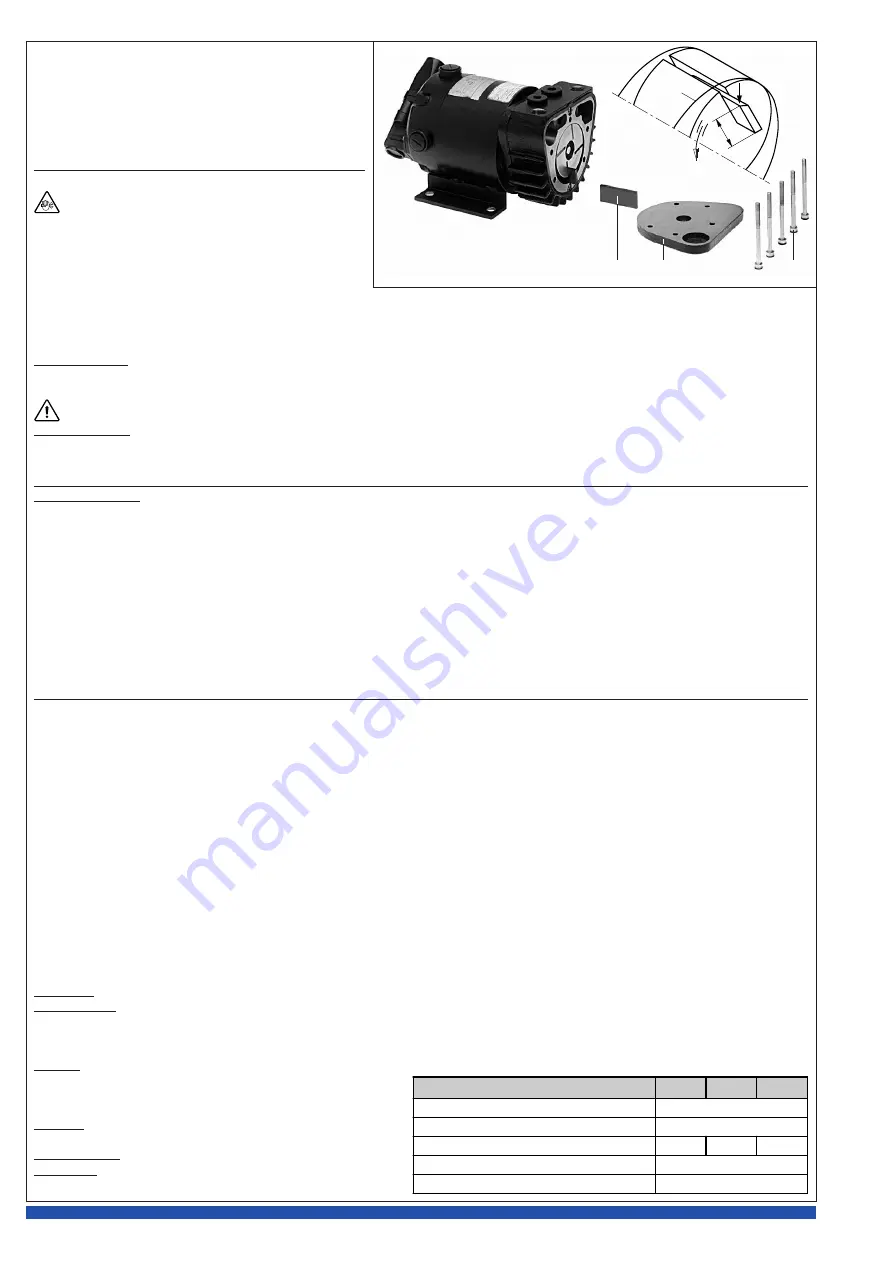

���

Z

Y

X

O

1

DTE 8

(50)

(51)

(52)

dB(A)

65

kg

9

mm

240

278

278

mm

128

mm

119

1.2001

Noise level (max.)

Weight

Length

Width

Height

Initial Operation (picture

���

)

1. Initially switch the compressor on and off for a few seconds

to check the direction of rotation. With right direction of

rotation, air leaves at the pressure connection (B)

Note: The pressure pipework should not be connected.

If the compressor runs backwards this could result in

damaged rotor blades.

2. Connect the pressure pipe at (B).

Maintenance and Servicing

When maintaining these units and having such situ-

ations where personnel could be hurt by moving

parts or by live electrical parts the compressor must be

isolated by totally disconnecting the electrical supply

after free-switching. It is imperative that the unit cannot be

re-started during the maintenance operation.

Do not maintain a compressor that is at its normal operat-

ing temperature as there is a danger from hot parts.

1. Lubrication

The DTE compressors have bearings that are greased for life. They need not be serviced.

2. Blades (picture

���

)

Checking blades: The models DTE have 4 blades which have a low but permanent wear factor.

First check after 6,000 operating hours, thereafter every 1,000 operating hours. Screw off housing cover (d) from housing. Remove blades (e)

for inspection. All blades must have a minimum height (X) of larger than 12 mm.

Blades must be changed completely.

Changing blades: if the minimum height is reached, then the whole set of rotor blades should be changed.

Before fitting new blades clean the housing and rotor slots with compressed air. Place the blades with the radius outwards (Y) so that the bevel

is in the direction of rotation (O

1

) and corresponds with the radius of the housing (Z). Replace housing cover (d) and slightly tighten the screws (s).

Start pump and check for free and smooth running blades. Then firmly tighten end cover screws (s).

Trouble Shooting:

1.

Insufficient pressure capacity:

1.1 Prefilter is obscured.

1.2 Pressure pipe work is too long or too small.

1.3 Leak on the compressor or on the system.

1.4 Blades are damaged.

2.

Compressor does not reach overpressure:

2.1 Leak on the compressor or on the system.

2.2 Blades are damaged.

3.

Compressor operates at an abnormally high temperature:

3.1 Ambient or suction temperature too high.

4.

Unit emits abnormal noise:

4.1 The compressor cylinder is worn. Solution: send your complete unit off for repair to the supplier or approved service agent.

4.2 Blades are damaged.

Appendix:

Repair on Site: For all repairs on site an electrician must disconnect the motor so that an accidental start of the unit cannot happen.

All engineers are recommended to consult the original manufacturer or one of the subsidiaries, agents or service agents. The address of the nearest

repair workshop can be obtained from the manufacturer on application.

After a repair or before re-installation follow the instructions as shown under the headings ”Installation and Initial Operation”.

Storage: DTE units must be stored in dry ambient conditions with

normal humidity. We recommend for a relative humidity of over 80%

that the compressor units should be stored in a closed container with

the appropriate drying agents.

Disposal: The wearing parts (as listed in the spare parts lists) should

be disposed of with due regard to health and safety regulations.

Spare parts list:

E 387 / 50

➝

DTE 8 (50), (51), (52)

Data sheet:

961271

➝

DTE 8 (50), (51)

961272

➝

DTE 8 (52)