Page 10

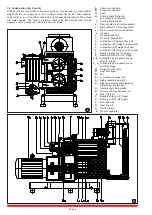

J

5

J

1

J

4

J

7

J

6

J

9

J

3

V

7

J

2

14

B

1

A

Q

1

X

1

Q

2

15

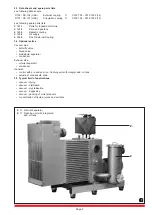

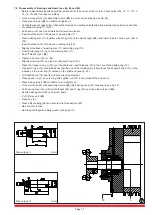

7.2 Oil Mist Separator (Optional Extra Exhaust Side)

The oil mist separator which is mounted directly on the

exhaust flange of the vacuum pump is a 2-stage device:

Separation:

➞

liquid droplets in the condensate collector

➞

aerosol in the filter elements

The oil mist separators are available in 2 material varia-

tions for the chemical and pharmaceutical industries:

➞

Stainless steel: 1.4541

➞

glass

The filter candles are made of teflon or borosilicate glass

and hence are fully resistant to solvents and largely

resistant to acids.

Please note: If the material being handled is subject to

polymerisation or resin hardening it is not advisable to use

this type of oil mist separator as the filter elements would

quickly become blocked and would require frequent chang-

ing.

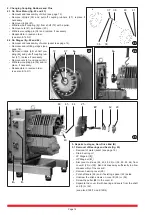

7.2.1 Oil Mist Separator Maintenance (fig. 14)

If the backpressure on the vacuum pump as shown on the

gauge (J

2

) rises to 0.5 to 0.6 bar then the filter candles (J

1

)

should be changed and the vessel (J

4

) cleaned out.

To change filter candles: after releasing the clamp screws

(J

5

) the oil mist separator cover (J

6

) and o-ring (J

7

) can be

removed. Remove the thumb wheels (J

8

) and take off the

locating plate (J

9

). Remove the filter candles (J

1

) and

before replacing the o-ring (J

7

) check it with particular

attention. During normal operation of the pump it is impor-

tant to ensure regular draining of the condensate and oil

mixture from the base of the separator and this can be

arranged for manual or automatic operation. A level switch

(V

7

) is fitted as standard and this will shut down the pump

when the exhaust condensate level becomes too high. For

the drain cock (J

3

) as shown a solenoid valve is available

for automatic drain of oil/condensate as an optional extra.

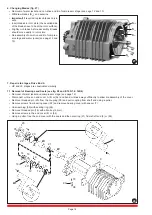

8. Trouble Shooting

8.1 Pump Overload

1. Check oil level in gear box (only when pump is stopped),

if necessary drain down to normal.

2. Measure back pressure in exhaust lines, if necessary

change filter elements.

3. Check ease of rotation of gearbox and pumpstages:

➝

remove motor and turn coupling.

8.2 Drop Off of Vacuum (pict. 15)

• Measure the vacuum directly at the vacuum connec-

tion (A), if necessary change mesh (A

1

).

• Measure the back pressure on the pump exhaust (B

1

).

It should not exceed 0.3 bar.

• If the ultimate vacuum was not achieved in the first

test:

- remove suction flange (X

1

), loosen circlip (A

2

), re-

move mesh (A

1

) and clean.

- remove inter-stage relief valve (Q) at (Q

1

) and check

operation as well as position of the valve.

• Measure the vacuum between the stages using tapping (Q

2

). If the same reading is obtained at suction flange (A) and (Q

2

)

then the LP stage is not functioning. If the reading at (Q

2

) is closer to atmospheric pressure, then the HP stage is not

functioning.

8.3 High Oil Consumption

• In case of bearing oil loss check the shaft seals between bearing and compressor stage and change (see page 14)

• High fresh oil consumption, check the non-return valves in the oil lines for correct function and replace. Disconnect oil lines

and check if they are under vacuum.

J

8

A

1

A

2

Q