Page 11

20

H

2

H

1

Y

5

Y

55

S

21

S

2

S

11

S

1

G

11

G

1

G

5

G

51

G

3

G

2

R

EPAIR

I

NSTRUCTIONS

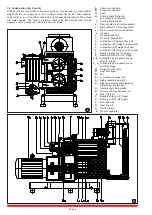

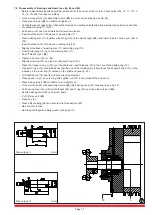

1. Removal and Re-assembly of Water Jacket (fig. 12, 13 and data sheets D 134 + D 137)

• Switch off VWZ and vent to atmospheric

pressure

• Open plug (U

25

) or (U

26

).

• Drain off cooling liquid:

- VWZ (14)

➝

drain cock (K

4

).

- VWZ (13)

➝

drain cock (K

4

). Drainage is

completed by opening plug (K

41

) at the base

of the radiator (R).

• Disconnect the cables of following devices

at the terminal box (G) :

- VWZ (14)

➝

thermostat (U

1

) and level switch

(V

4

).

- VWZ (13)

➝

thermostat (U), level switch (V

4

)

and fan (R

1

).

- Disconnection is unnecessary if you have a

cable conduit and open the cover.

• Remove plug (Y

42

) and turn eye bolts M 12.

• Support the water jacket at eye bolts (Y

42

) by

S-shaped hooks and crane.

• Remove the allen bolts (Y

41

) with an ex-

tended allen key (approx. 1 m).

• Separate the water jacket (Y

4

) from the

connection cover (Y

5

) with a crane and place

on wooden blocks.

• Refit the water jacket in the reverse order.

• Use new sealing rings if necessary.

• Fill with coolant at (H

4

).

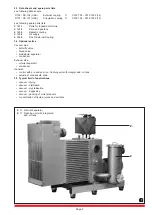

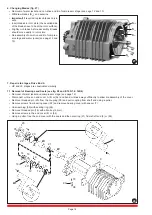

2. Changing LP and HP Stages (fig. 20)

• Removal and Refitting of LP and HP stages are the same.

2.1 Removal of Stages

• Remove water jacket (see above).

• Drain bearing oil:

- LP Stage at (K

1

) / HP Stage at (K

2

).

• Support stage (S

1

) or (S

2

) by slings from crane.

• Remove allen bolts (S

11

) or (S

21

).

• With gentle rocking movements, withdraw stage from flange complete with half coupling.

2.2 Refitting of Stages

• Before refitting, clean out the connecting passage ways (Y

55

) in the connection cover (Y

5

).

• When not replacing the stages, the ports (S

15

fig. 27) must be cleaned, taking care that no dirt enters the compression

chambers (S

16

fig. 27).

• Lightly smear both faces of gasket (30) with anti-seize, non-setting universal jointing compound (see E165/1).

• Refitting is reverse of removal.

• Use new sealing rings if necessary.

• Fill bearing oil tanks:

- LP stage at (H

1

) / HP stage at (H

2

).

• Refit water jacket (see above)

3.

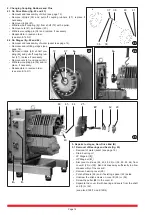

Removal and Reassembly of Drive (fig. 21)

• Disconnect cable of motor (G

1

).

• Remove hex-nuts (G

11

) and withdraw motor from mounting flange

(G

2

) with half coupling (G

3

).

• Remove hex-nuts (G

51

) from mounting flange (G

2

)

and separate from base frame (G

5

).

• Remove hex-nuts (G

21

) and withdraw

mounting flange (G

2

) from gear-

box housing (Y

3

).

• The half coupling (G

3

)

can now easily be

reached.

• Refit in reverse order.

´

` ¸

Y

3

21