Page 2

Contents

Page

Instruction and service manual VWZ 102 – VWZ 402

1.

Introduction

3

2.

Application

3

3.

Variations and Construction

3

3.1

Variations

3

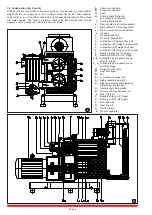

3.2

Construction

4

3.3

Data sheets and spare parts lists

5

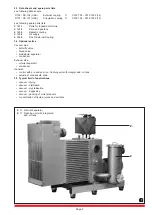

3.4

Accessories

5

3.5

Typical Field of Application

5

4.

Method of Operation

6

4.1

Pump

6

4.2

Pressure Relief Valve

6

4.3

Oil Lubrication

6

4.4

Shaft Seals

6

5.

Installation

6

5.1

Mechanical Installation

6

5.1.1

Mounting

6

5.1.2

Suction side

6

5.1.3

Exhaust

6

5.2

Electrical Installation

7

5.2.1

General

7

5.2.2

Approximate values for setting motor overload protection

7

5.2.3

Electrical connections for the motor and control equipment

7

5.2.4

Terminal Box Connections Closed Circuit Cooling

7

6.

Normal Operation

8

6.1

Cooling Liquid

8

6.1.1

Fresh or External Cooling

8

6.1.2

Closed Circuit Cooling

8

6.1.3

Cooling Liquid Control

8

6.2

Oil Lubrication

8

6.3

Oil Metering Pump

8

6.4

Initial Operation

9

7.

Maintenance

9

7.1

Oil Metering Pump

9

7.2

Oil Mist Separator

10

7.2.1

Maintenance of Oil Mist Separator

10

8.

Trouble Shooting

10

8.1

Pump Overload

10

8.2

Drop off of Vacuum

10

8.3

High Oil Consumption

10

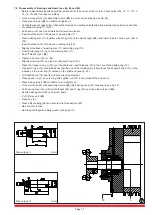

Repair Instructions VWZ 102 – VWZ 402

1.

Removal and Reassembly of Water Jacket

11

2.

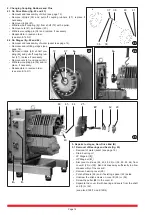

Changing LP and HP Stages

11

2.1

Removal of Stages

11

2.2

Refitting of Stages

11

3.

Removal and Reassembly of Drive

11

4.

Changing Coupling Rubbers and Pins

12

4.1

Drive Motor

12

4.2

On Stages

12

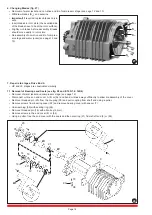

5.

Repairs to Stages, Non-Drive End (B)

12

5.1

Removal of Bearings and Seals

12

5.2

Reassembly of Bearings and Seals

13

6.

Changing Blades

14

7.

Repairs to Stages, Drive End (A)

14

7.1

Removal of Bearings and Seals

14

7.2

Reassembly of Bearings and Seals

15

8.

Repairs to Gearbox

16

8.1

Removal and Reassembly of Gearbox

16

8.2

Changing Gear Wheels and Ball Bearings in Gearbox Housing

16

8.3

Changing Bearings, Shaft Seals and Seals

17

9.

Other Repairs

17

9.1

Cleaning the Suction and Exhaust Parts in Connection Housing

17

9.2

Changing the Pressure Relief Valve

17

10.

Instructions for Storing Oil Metering Rotary Vane Vacuum Pumps

17