Page 4

4

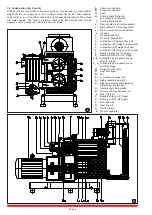

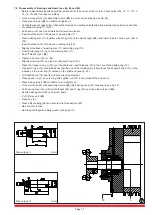

3.2 Construction (fig. 3 and 4)

VWZ pumps are constructed in five main sections, i.e. gear box (Y

3

), compression

stages (S

1

, S

2

), oil supply (L

1

to L

12

), cooling system (R, Y

40

, R

1

) and separator

systems (Z, J

1

, J

2

, J

3

) on the suction side and exhaust side (optional). The pumps

are water cooled. The built in pressure relief valve (Q) permits start-up and

operation of the pumps over the entire vacuum range.

A

Vacuum connection

B

Exhaust connection

G

1

Drive

H

4

Cooling liquid filling cap

and pressure relief valve

I

4

Cooling liquid check

J

1

Filter candles in oil mist separator

J

2

Manometer for oil mist separator

J

3

Drain cock for oil mist separator

L

Oil pump

L

1

Oil pump feed line

L

2

Oil pump leakage line

L

3

Lubrication (LP) stage drive end

L

4

Lubrication (LP) stage non-drive end

L

5

Lubrication (HP) stage drive end

L

6

Lubrication (HP) stage non-drive end

L

7

Bearing lubrication (LP) stage

L

8

Bearing lubrication (HP) stage

L

9

, L

10

Lubrication pump chamber and

slot (LP) stage

L

11

, L

12

Lubrication pump chamber and

slot (HP) stage

Q

Pressure relief valve

R

Heat exchanger

R

1

Fan

S

1

Low pressure stage (LP)

S

2

High pressure stage (HP)

U

High temperature and operating

temperature thermostat

U

2

Cooling liquid de-aeration

V

7

Level control condensate / oil

Y

Fresh oil tank

Y

1

Bearing oil tank (LP) stage

Y

2

Bearing oil tank (HP) stage

Y

3

Gear box unit

Y

30

Gear box oil

Y

40

Cooling liquid

Z

Oil mist separator

3