Page 8

U

1

T

Y

4

U

3

U

5

U

4

U

51

U

25

C

Y

41

Y

5

K

4

D

V

4

U

U

26

H

4

I

4

K

4

R

1

Y

5

K

41

U

2

R

Y

41

Y

4

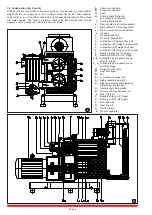

6. Normal Operation

6.1 Cooling Liquid

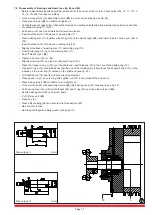

6.1.1 Fresh or External Cooling (fig. 12)

For starting-up the pump (VWZ 702 - VWZ 1202 (14))

first the water supply has to be connected to the hose

connection point (C). The water jacket (Y

4

) is filled by

pressing the spring loaded priming valve (U

4

). This

valve must be depressed until the water flows from

the hose outlet (D). The outlet hose may then be

connected. If rigid pipework has been connected to

the inlet and outlet points, then the bleed plug (U

25

)

should be loosened to allow the air to escape during

the priming operation and to ensure that the water

jacket is filled. This plug should be closed when the

water starts to seep from it. The water outlet pipe

connected to outlet (D) should exert no back pres-

sure on the water jacket (Y

4

).

Cooling liquid pressure higher than 0.3 bar

causes cracking of the water jacket.

The flow of cooling water through the jacket is

controlled by the thermostatic valve (U

3

) and its

sensor (U

31

) which can be set to operate in the range

50°C-90°C. The set temperature, which is chosen

according to the process conditions, will be con-

stantly maintained by the system and can be read off

on the thermometer (T) at the top of the water jacket.

If for any reason the temperature should rise above

this, the high temperature cut-out (U

1

) will shut the

pump down at a temperature of 90°C. This tempera-

ture is set in our works and should not be adjusted.

If a higher temperature is required to suit process

conditions please contact the manufacturer.

In order to keep the thermostatic valve clean a dirt

filter (U

3

) is fitted. This must be cleaned periodically,

depending on the water quality. To do this unscrew

the nut (U

51

) and clean the element.

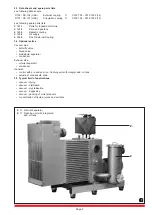

6.1.2 Closed Circuit Cooling (fig. 13)

For starting-up the pump (VWZ 702 - VWZ 1202 (13)):

The recommended coolant is a 50% antifreeze mix

which is poured into the heat exchanger at point (H

4

)

to a level midway up the upper sight glass (I

4

). The

filling should not take place under pressure and the

antifreeze should be well mixed beforehand. The

quantity required is shown on the data sheet D 137.

The coolant can be drained by opening the drain

cock (K

4

) on the water jacket (Y

4

) after removing the

vent plug (K

41

) at the cooler (R). To ensure complete

filling the bleed plug (U

26

) should be loosened.

6.1.3 Cooling Liquid Control (fig. 12 and 13)

The safety thermostat (U

1

) controls the temperature

of the coolant at the pump (fresh or external cooling).

When the pump is running, the safety- and operating

temperature thermostat (U) controls the switching on

and off the radial fan (R

1

) to maintain the pump at a

constant set temperature. When the pump is operat-

ing a slight pressure (approx. 0,3 bar) builds up in the

cooling system. The safety valve (H

4

) prevents this

pressure rising any further. Any air bubbles which

have formed during first filling or re-filling can escape

through the bleed valve (U

2

). For this to operate the cap (U

21

) on top of the valve should be unscrewed 2 to 3 turns.

If the location of the pump is such that there is a danger of freezing, then appropriate measures should be taken for both fresh

cooling and closed circuit cooling. The operating temperature can be set at according to process requirements between 50° and

80°C. If however, the operating temperature should continue to rise, the high temperature thermostat will shut down the pump

at a temperature of 90°C. If a higher temperature is required to suit process requirements, please contact the manufacturer.

U

21

U

2

12

Y

42

13