RF627Weld [Revision 1.1.1] 03.08.2020

Laser Seam Tracking System for Welding Automation. RF627Weld Series

65

#

Description

1

The scanner fixed to the robot transmits data to the controller (or to the PC with the Riftek Lamia

software installed).

2

Riftek Lamia processes the data in accordance with the selected math algorithm and transmits the

results to the robot controller over the selected protocol.

3

The robot controller makes decisions based on the received information. For example, corrects the

position of the welding torch during the welding process.

15.6.3. Connection procedure

Important!

Before connecting to the robot, it is necessary to activate the license for the Riftek Lamia

software. The license activation procedure is described in par.

.

To connect to the robot, start Riftek Lamia and perform the following steps:

Step

Description

1

Click the SEARCH button and connect to the scanner.

2

Go to the PROTOCOLS tab and click LOCK SENSOR.

NOTE:

This step is performed only once when connecting a new scanner. If the scanner has

previously been connected to the robot, you do not need to click the LOCK SENSOR button

again.

3

Select a protocol and configure parameters.

4

Enable the "State" option.

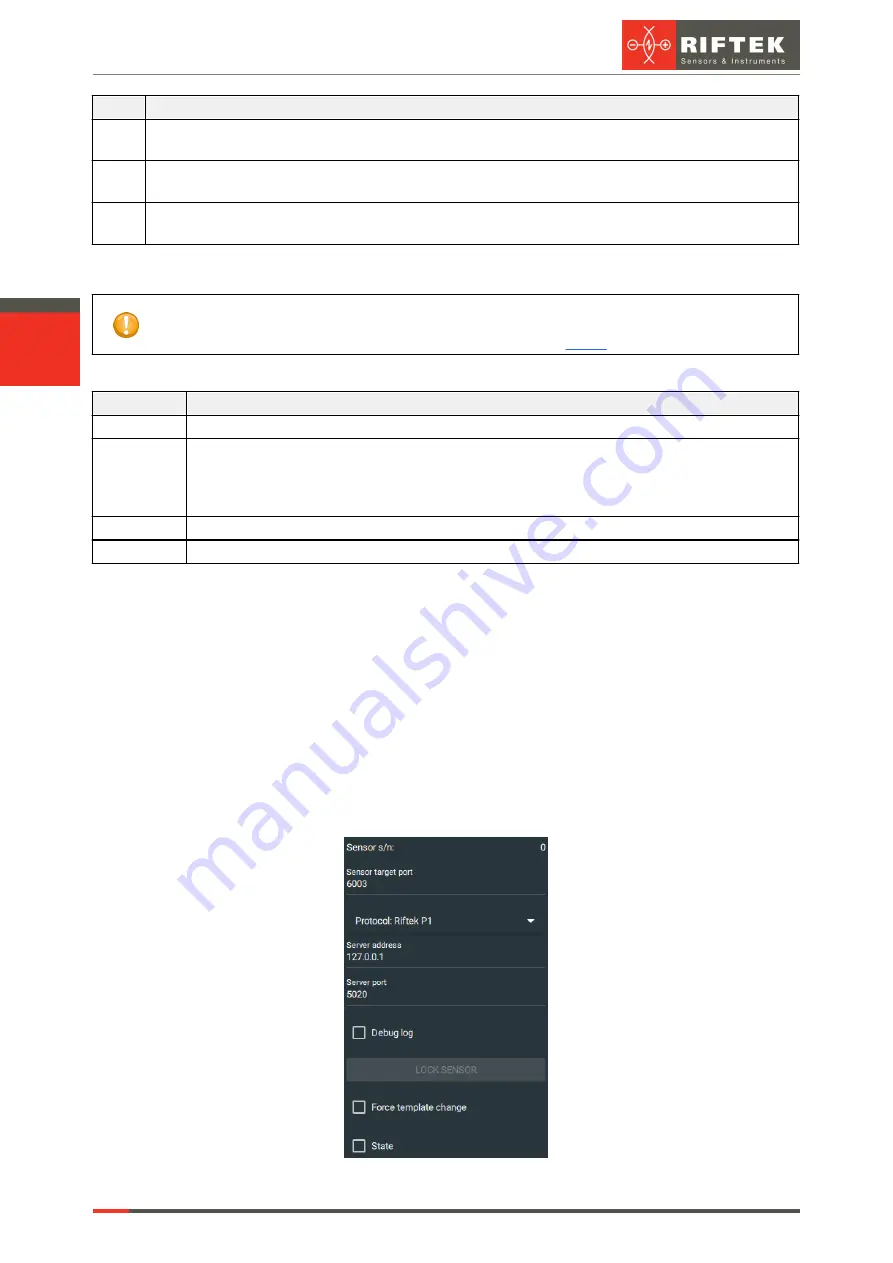

15.6.4. Riftek P1 protocol

15.6.4.1. General information

The

Riftek P1

protocol is based on the client-server model (

Riftek Lamia

is a

client, a robot is a server) and uses port 502 by default.

All values are hexadecimal, byte order – from left to right.

After turning on/off the Modbus function, the scanner must be rebooted. The TCP

connection temporary deactivates the Modbus function; when activating the Modbus

function (the scanner finds the IP address and successfully connects to port 502), other

scanner functions will be deactivated (including TCP).

The

PROTOCOLS

tab with the

Riftek P1

protocol selected: