RF627Weld [Revision 1.1.1] 03.08.2020

Laser Seam Tracking System for Welding Automation. RF627Weld Series

73

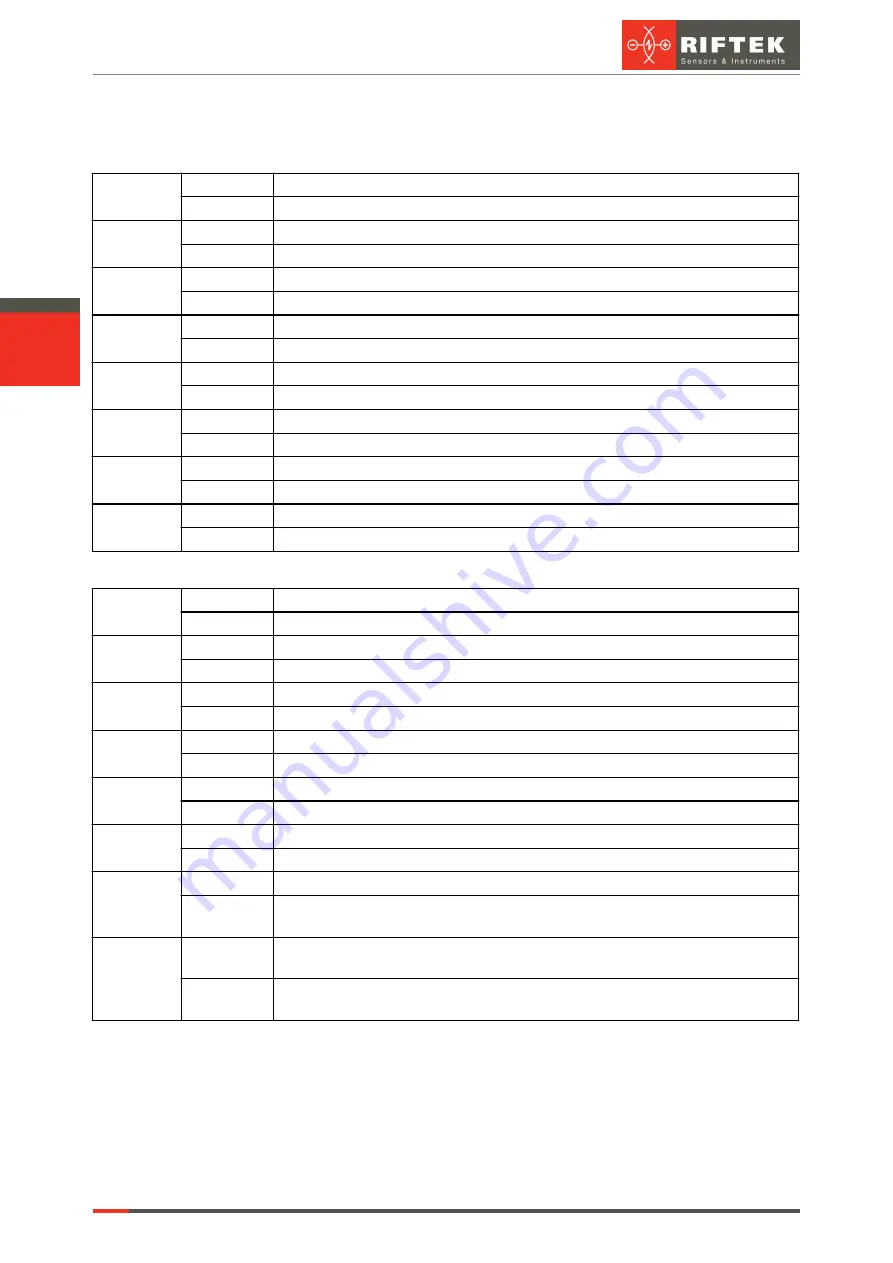

15.6.6.2. Holding registers

Read holding registers:

16 bit

15 bit

Scanner 3D Point X * 10 (absolute value).

1 bit

Least significant bit.

16 bit

15 bit

Scanner 3D Point Y * 10 (absolute value).

1 bit

Least significant bit.

16 bit

15 bit

Scanner 3D Point Z * 10 (absolute value).

1 bit

Least significant bit.

16 bit

8 bit

The latest counter that was received from the robot (unsigned).

8 bit

Reserved.

16 bit

15 bit

Robot P * 10 (absolute value).

1 bit

Least significant bit.

16 bit

15 bit

Robot R * 10 (absolute value).

1 bit

Least significant bit.

16 bit

15 bit

Scanner 2D Point X * 10 (absolute value).

1 bit

Least significant bit.

16 bit

15 bit

Scanner 2D Point Y * 10 (absolute value).

1 bit

Least significant bit.

Write holding registers:

16 bit

15 bit

Robot X * 10 (absolute value).

1 bit

Least significant bit.

16 bit

15 bit

Robot Y * 10 (absolute value).

1 bit

Least significant bit.

16 bit

15 bit

Robot Z * 10 (absolute value).

1 bit

Least significant bit.

16 bit

8 bit

Robot W * 10 (absolute value).

8 bit

Least significant bit.

16 bit

15 bit

Robot P * 10 (absolute value).

1 bit

Least significant bit.

16 bit

15 bit

Robot R * 10 (absolute value).

1 bit

Least significant bit.

16 bit

8 bit

Packet counter (unsigned).

8 bit

Command (unsigned): 0 - no command, 1 - laser ON, 2 - laser OFF. If the

command is the same as previous, nothing will happen.

16 bit

8 bit

Template set selection (unsigned): 0 - Measurement, 1 - Welding. If the

template set number is the same, nothing will happen.

8 bit

Template selection (unsigned). If the template number is the same, nothing will

happen.

15.6.6.3. Operation logic

1) The robot writes at least six registers (will be taken only six, starting with zero) by

six coordinates in the following format: 15 bit - value, 1 least significant bit - sign. The float

value transmitted by the robot will be multiplied by 10 in order to contain 1 digit after the

point.