28 |

P a g e

R i g e l M e d i c a l U n i - T h e r m u s e r M a n u a l V 1 . 0

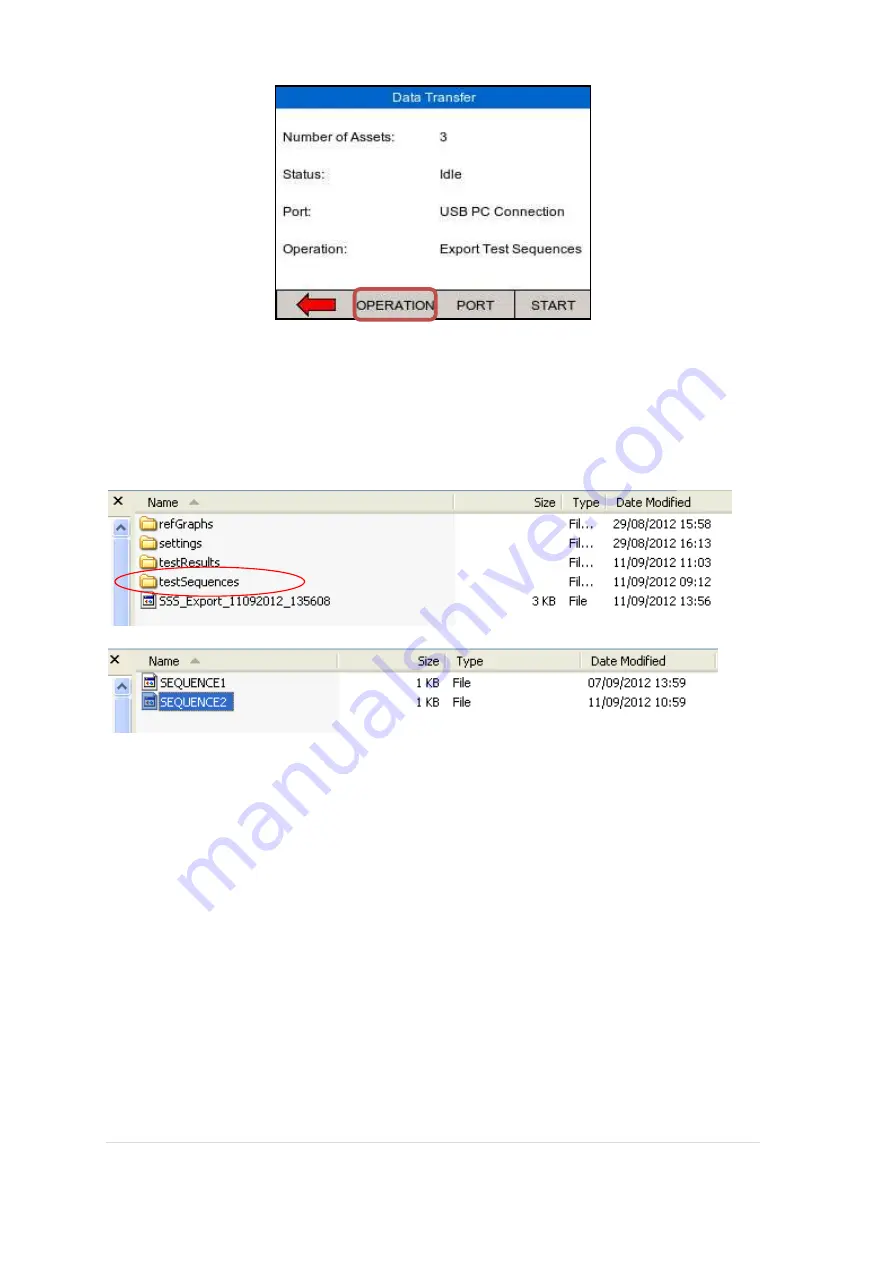

Press start to connect the Uni-Therm as an external drive to the PC.

Using Med-eBase, import the test sequences by following the instructions in the Med-

eBase instruction manual.

When using windows Explorer, locate the REMOVABLE DISC and navigate to the

corresponding folder;

Select the sequence (or all) and copy them to a folder of choice.

The files can then be shared between other PC’s and uploaded back into other Uni-

Therms.

To import the test sequence(s), put the sequence in the corresponding folder as shown

above. The new test sequences will now appear in the Uni-Therm test sequence library.