- 7 -

E

N

G

L

IS

H

TECHNICAL DATA

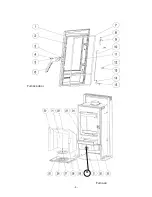

(Fig. 1 - fitting dimensions)

This is a Design 1 fire and has a connection for

fitting to a chimney that is equipped for other fires

and boilers for solid and liquid fuels, insofar as the

chimney dimensions are in accordance with DIN

4705, Part 3.

Exhaust values for multiple use of the chimney

according to DIN 4705, Part 3 or to dimension

the chimney according to DIN 4705, Part 2

Exhaust mass flow

7,4 g/s

Exhaust temperature

218,8°C

Minimum feed pressure at rated

useful heat

12 Pa

The owner of the small heating system or the

authorised person for the small heating system

must keep the technical documentation in a safe

place and present it to the local authority or the

chimney sweep.

THE PACKAGING

Your first impression is important to us!

The packaging of your new stove provides excellent

protection against damage. However damage to the stove

and accessories may still occur during transport.

Therefore please check your stove on receipt for

damage and completeness! Report any deficiencies to

your dealer immediately! Pay particular attention

during unpacking that the stone and ceramic panels

remain intact. Scratches to the material can easily

occur. Natural stone and ceramic panels are excluded

from the warranty.

The packaging of your new stove is environmentally

neutral to a great extent.

The wood used in the packaging has not been surface

treated and may therefore be burnt in your stove. The

cardboard and film (PE) can be disposed of via the

municipal waste collection for recycling.

PARTS - OVERVIEW

DESCRIPTION

1 Fire door machined and painted

2 Door glass

3 Disk spring D16x8.2x0.9

4 Handle

5 Hexagon socket screw

6 Fire door handle

7 Toroidal sealing ring

8 Fire door bolts

9 Top fire strip

10 Torsion spring

11 Sealing ring flat CULIMETA

12 Glass holder

13 Hexagon bolt

14 Bottom fire strip

15 Hinge nut black, galvanised

20 Fire clay front left

21 Fire clay rear

22 Flue plate

23 Shaker grate handle

24 Wood stop painted

25 Shaker plate

26 Base tray

27 Hexagon socket screw V2A

28 Fire clay front right

29 Fire clay side

30 Rotary control knob

31 Wood compartment cover

32 Ash drawer

33 Lock complete

40 Soapstone lid for rear connection (optional)

41 Lid soapstone for top connection

42 Bolts

43 Transport mount

44 Fiberfax

45 Side panel soap stone

46 Rear wall

47 Flue gas connection

48 Cooking lid

49 Recessed head screw

50

Air regulation

TECHNICAL SPECIFICATION

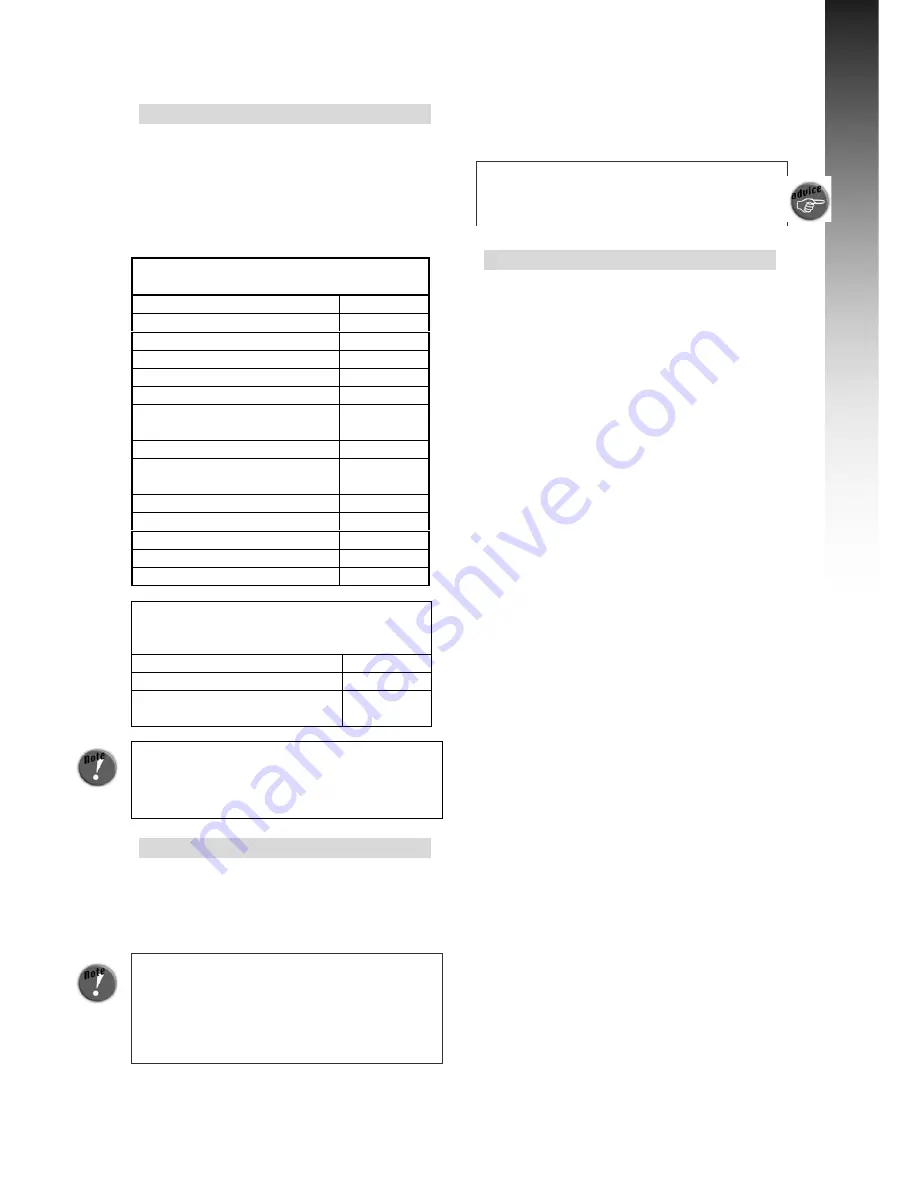

Dimensions (mm) and weights (kg)

Height

1201

Width

610

Depth of the corpus

465

Weight excluding casing

135

Weight with soapstone casing

395

Flue pipe outlet diameter

130

Rated useful heat according to

EN13240

8 kW

Smallest thermal output

4 kW

Room-heating capacity

depending on house insulation

90-210 m3

Fuel flow

2,2 kg/h

Efficiency

81,4 %

CO2 content

9,2 %

CO emission rel. 13% O

804 mg/Nm3

Dust emissions

28 mg/Nm3

Summary of Contents for tara

Page 1: ...1 TARA Instruction Manual...

Page 2: ...2...

Page 3: ...3 Fitting dimensions...

Page 4: ...4 30 Furnace Furnace door...

Page 5: ...5 50 Panel...

Page 21: ...21...

Page 22: ...22...

Page 24: ...24 Z32829 2011 12 05 G U A R A N T E E G A R A N T I E Customer Client To A Stamp Marque...