4 How to Use

4-6. How to tube

GD-D58 Series

- 32 -

CAUTION

The longer the tube of the GAS IN is, the longer it takes for a sample gas to reach the detector

head. The length of the GAS IN tube must be minimized, since some gases have a highly

adsorptive property which results in slower responses, and possibly a lower reading than the

actual value.

When the humidity in the sampling point is high, condensation may be formed inside of the

tube. (Make sure to avoid condensation when using a gas such as a strong acid gas, which is

dissolved into water and corrodes contacted materials, because it may result in undetectable

condition and furthermore may corrode internal parts.) Also avoid an excessive U-shaped or V-

shaped tube.

Determine the inlet for the sample gas, considering the air flow of the sample gas line and the

gas generating process.

To remove dust, never fail to attach the supplied dust filter in the middle of the tube.

It is needed to decide the length and material of the tube. Please contact RIKEN KEIKI for more

information.

Do not use the detector head under an inert gas atmosphere. The flow rate cannot be detected

correctly under an inert gas atmosphere such as He.

During tubing work, do not bend tubes at a right angle but install them as straight as possible.

Applying too much load on a tube may put too much strain on the pump of the detector head

and shorten the pump life.

If bending of a tube is unavoidable, bend it with an appropriate radius to minimize strain.

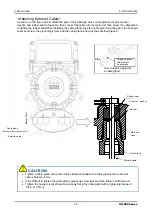

4-6. How to tube

The detector head has an Rc1/8 thread inside of the sampling inlet/outlet (GAS IN, GAS OUT), to which

BS unions are attached as standard. Because their material varies depending on the gas to be detected,

please specify the material.

The compatible tube is a copper tube of

Φ

8 (OD) -

Φ

6 (ID). The tube must be installed with the supplied

sleeves attached to prevent a leak.

When the tube is cut, its cut point may have a smaller inner diameter. Use a file etc. to expand the inner

diameter of the cut point. To remove cut-dust remaining inside of the tube, blow compressed air etc. into

the tube before connecting it to the detector head.

Some sample gases have highly adsorptive or corrosive properties. Select the tube material taking into

account these precautions.

WARNING

The detector head is designed to draw gases under the atmospheric pressure.

If excessive pressure is applied to the sampling inlet and outlet (GAS IN, GAS OUT) of the detector

head, detected gases may be leaked from its inside, thus leading to dangers. Avoid applying

excessive pressure to the detector head while in use.

Gases must be exhausted from the gas exhausting outlet (GAS OUT) to which an exhaust tube is

connected, to a point regarded as a safe place.

Do not use the detector head in the presence of silicone or sulfides.

The gas sensing part of the gas sensor and flow sensor is made of metal porous sintered alloy

permeated with an oxidation catalyst. If silicon or sulfide compounds are accumulated on the

surface of porous sintered alloy, the area of the gas sensing part becomes smaller, which may result

in serious deterioration of its sensitivity.

Do not use the detector head under an inert gas atmosphere. The gas cannot be detected correctly

under an inert gas atmosphere such as He.