7 Maintenance

7-2. Parts replacement

- 39 -

GD-D58 Series

7-2. Parts replacement

<Gas Sensor, Flow Sensor, and Pump Replacement>

Our service engineers need to replace and calibrate these parts. Please contact RIKEN KEIKI.

NOTE

The gas calibration using the standard gas is required after the gas sensor is replaced. Adjustment is

required after the flow sensor or pump is replaced. Please contact RIKEN KEIKI.

As a guide, replace the sensors of the detector head with new ones every one to three years.

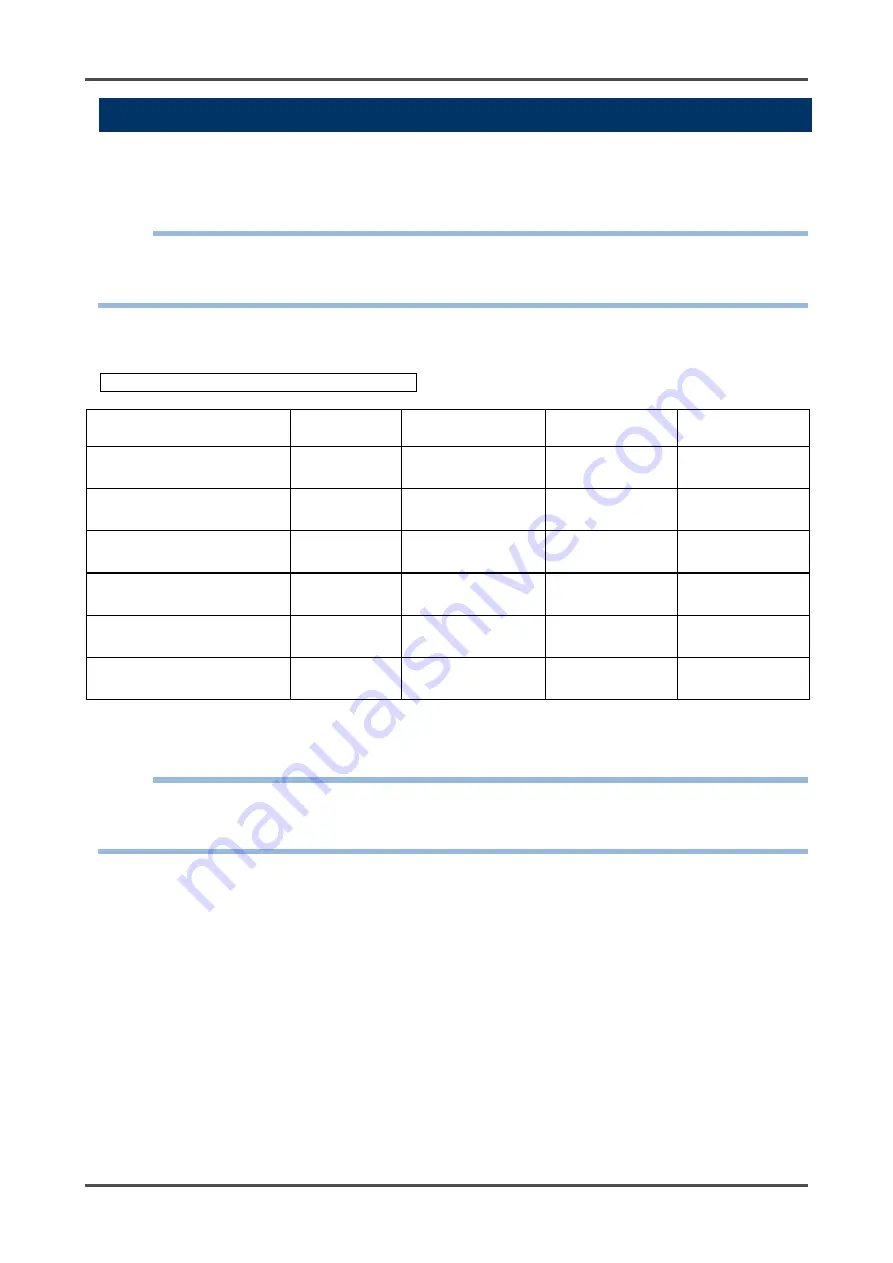

<Replacement of Regular Replacement Parts>

List of recommended regular replacement parts

Name

Maintenance

intervals

Replacement

intervals (year)

Quantity

(pieces/unit)

Remarks

AC/DC converter

6 months

3 - 6 years

1

※

Flow sensor

6 months

2 years

1

※

Tubes

6 months

3 - 8 years

1

※

Pump unit

6 months

1 - 2 years

1

※

Chamber assembly

6 months

3 - 8 years

1

※

Sensor cap assembly

6 months

3 - 8 years

1

※

※

After the part is replaced, the operation must be checked by a qualified service engineer.

For the stable operation of the detector and safety, ask a qualified service engineer to take care of

replacement of the parts whose operation must be checked. Please contact our sales department.

NOTE

The above replacement intervals are recommendation only. The intervals may change depending on the

conditions such as the operating environment. These intervals do not mean the warranty periods either.

The result of the regular maintenance may determine when to replace the parts.