14

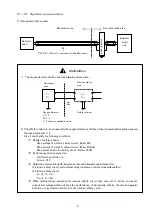

6-2.How to calibration

Perform gas calibration at new installation, 6 months maintenance and sensor replacement.

6-2-1.Required kit and tools for calibration

Prepare following jigs and tools to perform zero and span adjustments.

Calibration gas (standard gas for zero and span)

Gas sampling bag for calibration gas.

Gas sampling bag for exhaust gas.

Suction pump to lead calibration gas

Flow meter with flow control valve (enable to control 1.0L/min).

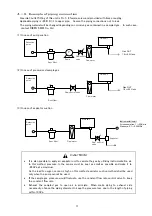

6-2-2.Performing a zero adjustment

①

Pack the zero gas (Nitrogen more than 99.9 vol %) into gas sampling bag.

②

Disconnect piping for both gas inlet and gas outlet of this unit.

③

Connect flow meter (with flow control valve) and suction pump to the detector head. Turn on the

pump and adjust the reading of flow meter to 1.0±0.3L/min.

④

Connect gas sampling bag for calibration to the IN side of the pump and gas sampling bag for

exhaust gas to the outlet of this unit respectively.

⑤

After reading by indicator/alarm unit gets stable, adjust the reading to zero with respective

potentiometer of indicator/alarm unit.

⑥

Stop the supply of zero gas, disconnect gas sampling bag for calibration and confirm that the

oxygen reading returns to 20.9vol %.

⑦

Return disconnected piping to where they were (completion of zero adjustment).

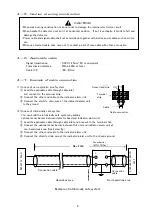

6-2-3.Performing a span adjustment

①

Pack the span gas (fresh air for oxygen deficiency alarm instrument and their concentration is

around preset alarm level for other purpose) into gas sampling bag. For simple calibration, you

may be possible to use an ambient air as span gas containing 20.9vol% O

2

providing that the

ambient pressure is 1 atm (1000±50hPa) and contamination in air is negligible against span gas

concentration.

②

Disconnect piping for both gas inlet and gas outlet of this unit.

③

Connect flowmeter (with flow control valve) and suction pump to the detector head. Turn on the

pump and adjust the reading of flowmeter to 1.0±0.3L/min.

④

Connect gas sampling bag for calibration to the IN side of the pump and gas sampling bag for

exhaust gas to the outlet of this unit respectively.

⑤

After reading by indicator/alarm unit gets stable, adjust the reading to the span gas concentration

with respective potentiometer of indicator/alarm unit.

⑥

Stop the supply of span gas, disconnect gas sampling bag for calibration and confirm that the

oxygen reading is 20.9vol %.

⑦

Return disconnected piping to where they were (Completion of span adjustment).

Summary of Contents for GD-F4A-A

Page 1: ...PT2E 2501 Oxygen Gas Detector Head GD F4A A Operating Manual PT2 151...

Page 25: ......

Page 26: ...1...