7 Maintenance

7-2. Regular maintenance mode

- 34 -

SD-2600

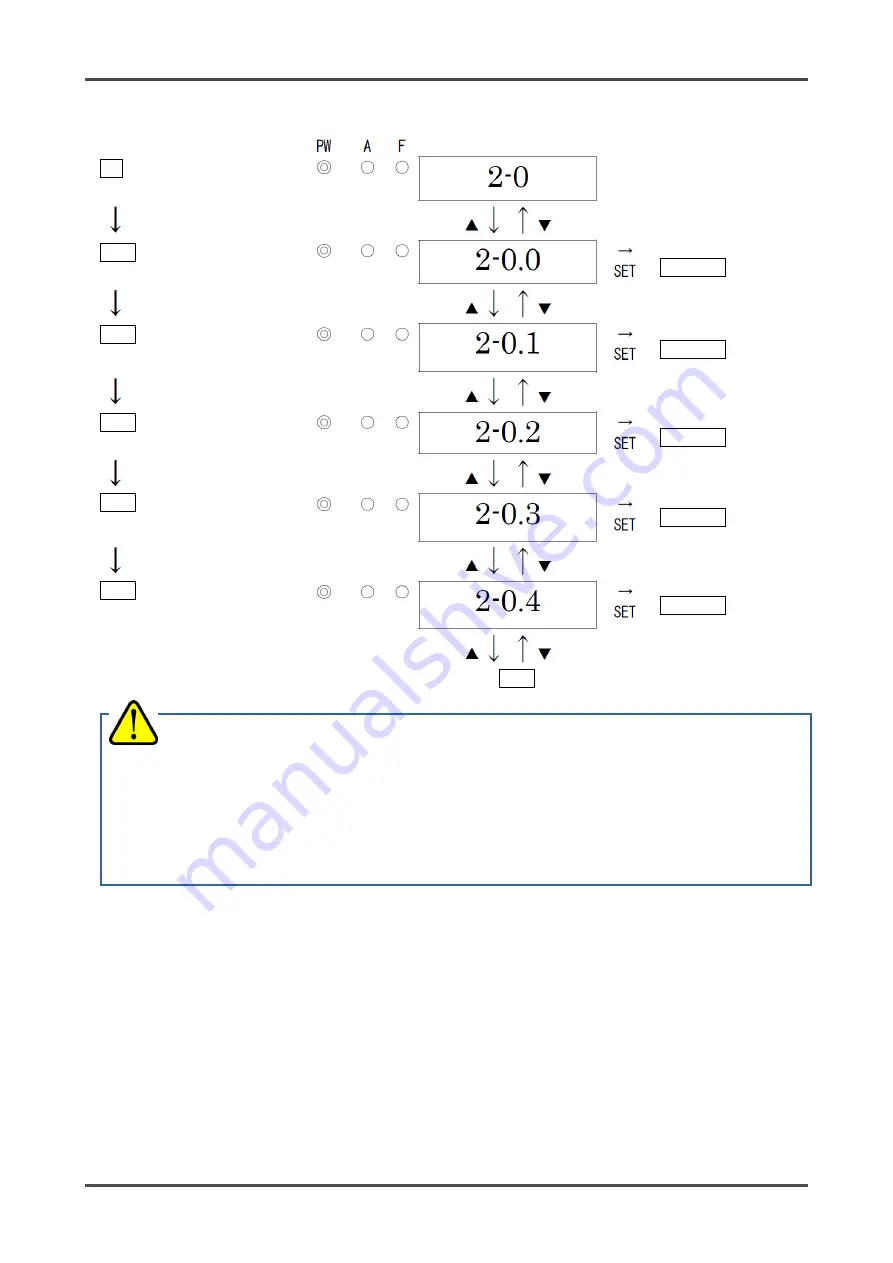

<Alarm Test Mode "2-0">

2-0

Press the SET key.

Gas Test

=> P35

2-0.0 Gas Test

Alarm Test

=> P35

2-0.1 Alarm Test

Fault Test

=> P36

2-0.2 Fault Test

LED Test

=> P36

2-0.3 LED Test

Memory Test

=> P37

2-0.4 Memory Test

To 2-0.0

WARNING

Before starting the alarm test (transmission test), provide a notification to the related sections so that

they can prepare for false abnormalities (external output signals and alarm contact). After the test is

completed, never fail to press MENU/ESC key to return to the detection mode. (If the gas monitor

remains in the alarm test mode, it automatically returns to the detection mode in ten hours.)

In the alarm test mode, the gas concentration equal to the reading is output even in the maintenance

mode depending on the setting. Take actions, if necessary, so that the signal receiver side can

prepare to avoid false alarms.

LED