15

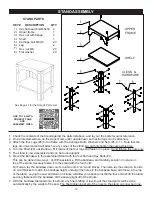

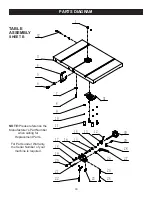

FIGURE 19

ADJUSTMENTS

ADJUSTING THE BLADE TENSION

1. Always tension the blade with

the Quick Release Lever (#17C) in the “ON” position.

Failure to do so could result in lack of blade tension or

tension failure. Figure 16.

NOTE:

Release / turn ‘OFF’ the Tension Lever only to

change the blade, or to prolong the life of the blade

when the saw is not in use for extended periods.

2. To adjust the blade tension, turn the Blade Tension

Handwheel (#1D, Fig. 17) on the top of the saw.

To tighten the tension of the blade, turn the hand

wheel clockwise. Tension the blade until the Tension

Indicator Arrow (#16A, Fig. 19) corresponds to the

width of blade you are using. View the indicator Arrow

through the top door’s front window. Fig.18.

NOTE:

The blade tension scale may read

differently due to different blade specifications from

manufacturers - steel thickness, material, or variations

in the welded blade length. It may be necessary to

adjust the tension arrow up/down one size on blade

tension scale to match your blade. Note the blade

setting for the next time the same blade is used.

General Rule

for blade tension: With the saw

unplugged and the blade guard up, the saw blade

should deflect about 1/4” when pressed with a finger

to the side of the blade.

See page 16 for information on ‘Adjusting the Blade

Tension Stop’ for tensioning blades that are welded a

bit longer than the specified 111” length.

NOTE:

Excessive counterclockwise turning of the

Blade Tension Handwheel to release blade tension

may unscrew the threaded Blade Tension Rod

(#2C) from its tapped Block (#13C, Fig. 19, C). If

this occurs, blade tensioning is impossible as the

handwheel will just freely turn. The Rod must be re-

threaded into the Block to resume blade tensioning.

ADJUSTING THE BLADE TENSION INDICATOR

The Blade Tension Indicator Arrow (#16A, Fig. 19, A)

should be checked and adjusted the first time the

saw is set up and run, and whenever a new blade is

installed.

The blade tension indicator should be adjusted for

blades made from thicker steel, if over cut or undercut

in length, or made by different manufacturers.

FIGURE 16

FIGURE 17

Quick Release Lever

ON

OFF

FIGURE 18

THE MACHINE MUST NOT BE

PLUGGED IN AND THE POWER SWITCH MUST BE IN THE

OFF POSITION UNTIL ALL ADJUSTMENTS ARE COMPLETE.

A

B

C

1. With moderate tension on the blade, loosen

the Indicator Plate’s adjusting Screw (#14A) with a

Phillips head screw driver (Fig. 19, B).

2. Adjust the blade indicator up/down as needed and

then tighten the plate’s adjusting screw.

Summary of Contents for 10-324TG

Page 43: ...43 OPERATION...